Value Stream Mapping and Design

How can you safeguard your company’s ability to remain competitive? Do you have a complex product, multi-stage production and consequently a complex production process? Do you want to be able to implement the principles of lean manufacturing as well as meet customer requirements in your factory? Would you like to change from cumbersome push control to lean and flexible value stream management?

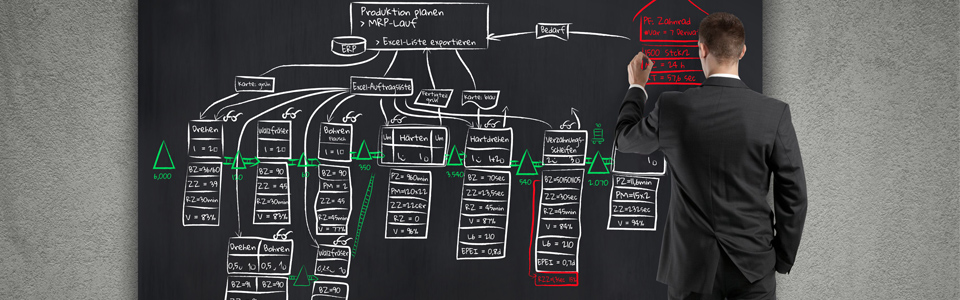

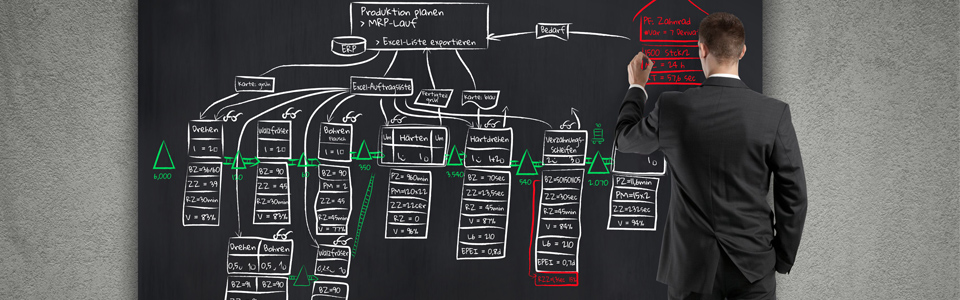

To optimize production processes, Fraunhofer IPA has been applying the value stream method with great success in all branches of industry for more than 20 years. With the aid of value stream analysis, a factory’s status quo can be systematically recorded with all the relevant parameters and assessed with key figures. The resulting value stream map clearly visualizes the entire production process, including the flow of materials and information. This enables any wastage to be easily identified. Fraunhofer IPA particularly focused on further improving how complex information flows are recorded at contract manufacturers and in companies where multiple product variants are fabricated.

Value stream design is used to methodically develop an optimized production state. To this end, Fraunhofer IPA has developed eight design guidelines, which are applied systematically in a predefined order and have been tried and tested in numerous industrial projects. In this way, throughput times can be radically shortened, and the production process is much easier to control. For complex applications such as when it comes to made-to-order products, different product models, or order-related production, Fraunhofer IPA has supplemented its value stream design with new solution modules that take the lean concept even further. One of these is the definition of clear and simple sets of rules for order approval and production control.

Optimizing the production process with value stream design gives you the following advantages:

- Clear overview of the entire production process, including identification of potential for improvement for throughput times and capacities

- Factory audit with identification of wastage

- Drastic reduction in throughput times and stocks on the shop floor

- Improved adherence to delivery deadlines due to clear, transparent processes

- Synchronized production processes

- Design of a simple control logic with smooth production and a balanced range of products

- Optimized lot sizes according to EPEI logic

- The benefit of our extensive planning experience

- Recommendations for future factory planning projects

Further information

- Publication on “Value stream mapping and design” (publica.fraunhofer.de)