Mobile Manipulation

Tabbed contents

Expertise

General information

As the use of service robots becomes more widespread in industrial and everyday environments, such systems have to execute more and more different tasks and meet rising requirements. In intralogistics, assembly as well as fetch-and-carry duties in the home, robots have to be capable of performing complex motion sequences safely and robustly. Compared to industrial robots with fixed safety equipment, a service robot's environment is much more complex. Neither humans nor the environment may be endangered at any time. Moving and unknown objects need to be especially considered in motion planning and execution. The robot system also has to be able to react appropriately and, more importantly, rapidly to changes in its environment. Further requirements need to be met in cases where mobile platforms are combined with different manipulators, especially when synchronizing and coordinating overlapping movements.

Expertise and sample projects

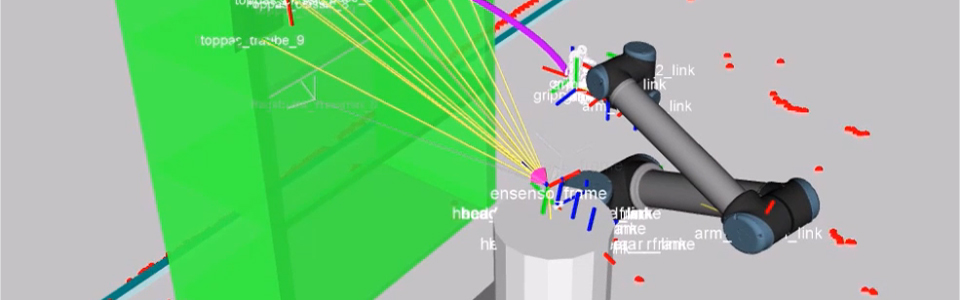

Fraunhofer IPA has a wealth of experience in the field of manipulation with mobile service robots. The department has its own flexible software environment, in which fundamental algorithms for kinematic calculations are united with diverse components for collision-free manipulation. Intelligent control-based methods for synchronizing and coordinating the movements of several actuators are also integrated into the control software.

In previous projects (e.g. R3-COP), various components were developed to enable a robot to clear a table autonomously. In the project interAID, a mobile robot was used to operate a washing machine for a quality assessment procedure. In a later project, these components were extended to create a flexible system for automated dishwasher stress tests.

Services

As your partner, Fraunhofer IPA supports you throughout the entire development of your service robot application:

- Advice on designing a mobile service robot, especially on selecting the right hardware

- Implementation of control software for your robot system, integration of various modules into existing controllers as well as the development of new application-specific components for your control system

- Consulting services, design and realization of complex manipulation tasks and applications

Project videos

Privacy warning

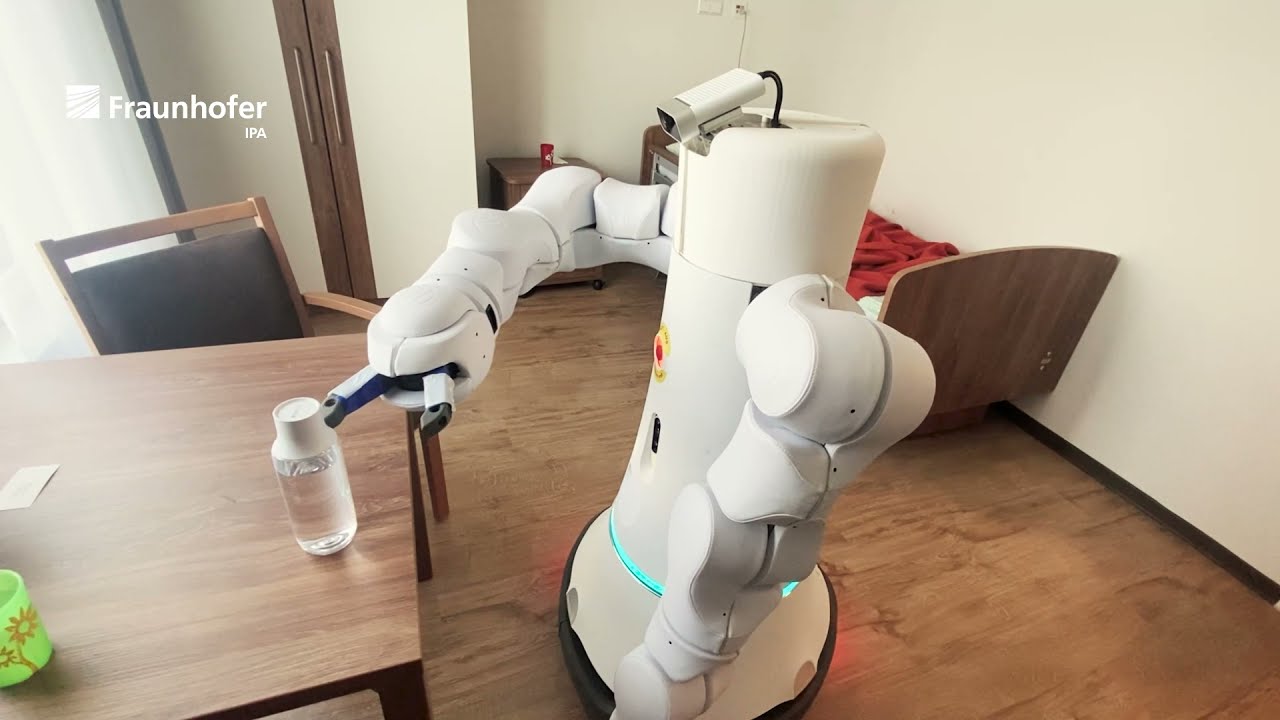

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacySupporting the staff in eldercare facilities by exchanging water bottles with Care-O-bot 4.

Kommissionierroboter für den Einzelhandel und Warenlager

Care-O-bot 3: Kollisionsfreie Manipulation

Care-O-bot 3: Mobile Manipulation

»Twist Control« with Care-O-bot 4

»Twist Control« with SCHUNK LWA 4D