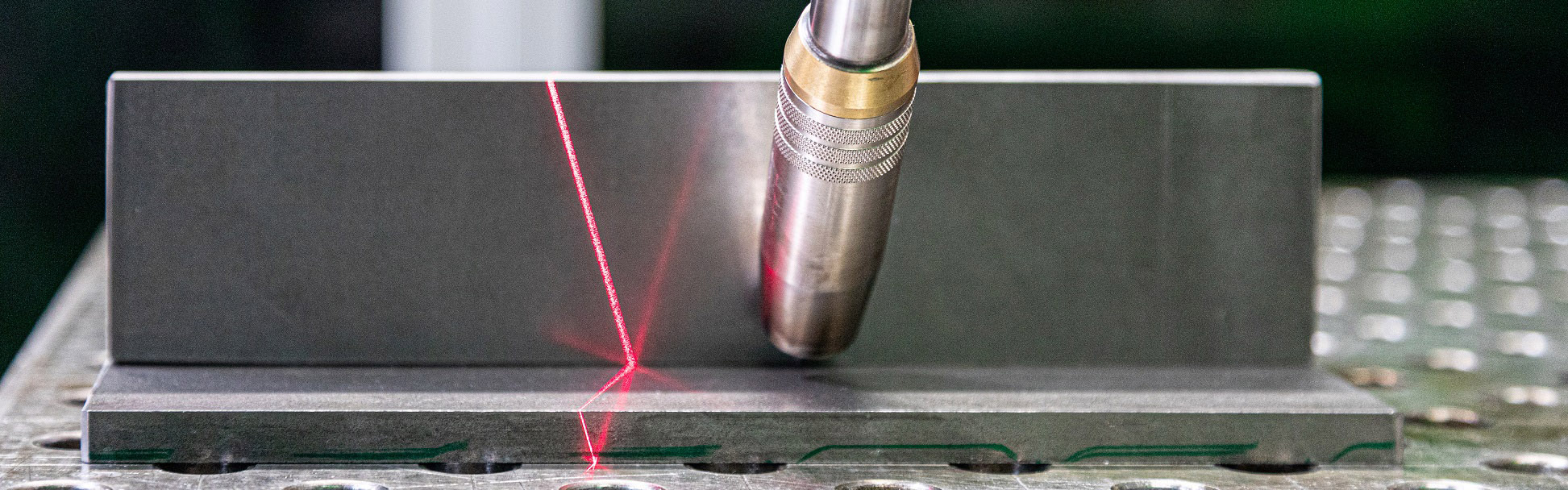

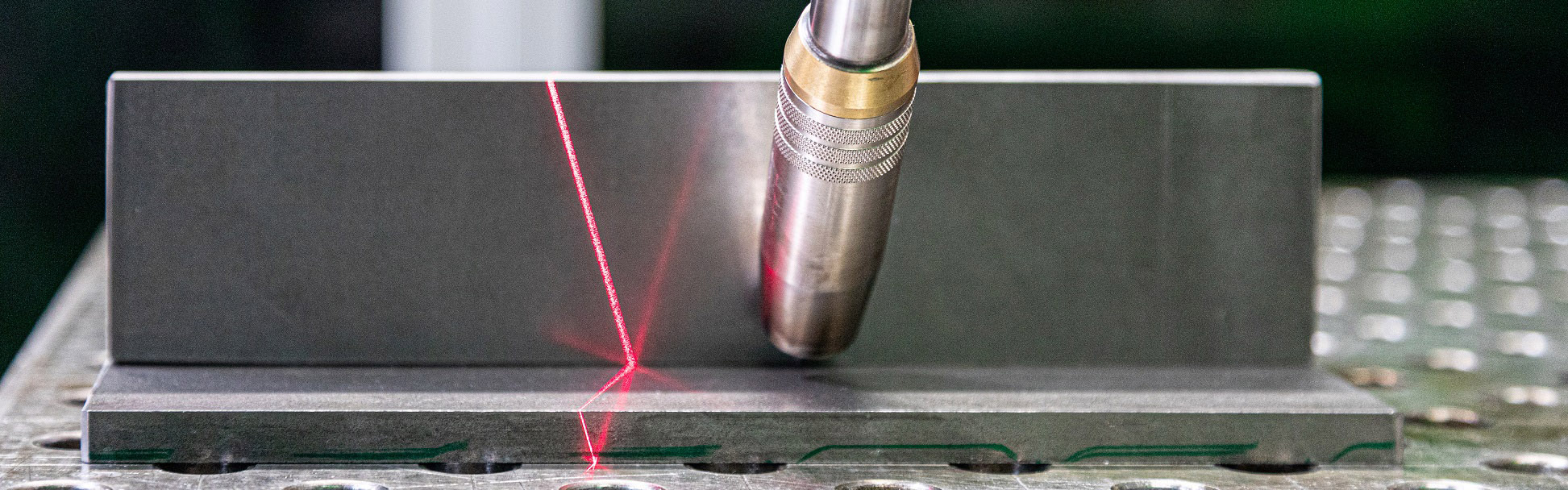

Welding and Machining

Tabbed contents

Expertise

Precision, large work spaces and high payloads: industrial robots offer enormous potentials to automate welding and machining tasks and other continuous-path processes. However, the high accuracy requirements and programming efforts are major hurdles for the use of welding robots, especially for small batch sizes. Fraunhofer IPA is therefore developing methods, technologies, components and software modules to make path processes with industrial robots more accurate and less expensive:

- Technologies for faster programming of the robot system using ROS (Robot Operating System)

- Technologies to improve the accuracy of the robot system

Services

- Manufacturer-independent analysis of your requirements with regard to ease of automation and assessment of cost-effectiveness

- Design and simulation of robot systems for arc welding, deburring, rounding, boring and machining

- Execution of tests with welding and machining systems from Fraunhofer IPA

- Development, implementation and integration of peripheral components

- Integration of sensors and configuration of software for sensor data analysis and process tracking

- Development and implementation of software for fast and simple programming

- Automation of sub-processes

- Realization and implementation of robot systems, including CE-label certification, in collaboration with systems integrators

- Measurement, evaluation and optimization of existing systems

Advantages

The large work space, precision and endurance of robots offer enormous potentials to increase manufacturing efficiency. Thanks to advances in sensor and computer technology, robot programs can now be generated either fully- or partially-automatically. As a result, robots are being used to improve cost-effectiveness in industrial manufacturing, even in cases where small and average batch sizes are produced.

- Fast intuitive programming

- Automated path-planning and program generation

- High-precision detection of objects and tolerances

- Improved accuracy of industrial robots

- Calibration of robot tools and sensors

- Safety systems for industrial robots