Process Development in Electroplating

Layer properties and surface functions

The aim of applying an electroplated layer is always to create one or more surface properties for a component. In addition to widely known and typical properties such as corrosion resistance, corrosion protection, wear resistance, hardness and gloss or shine, these can also be more specific surface functions such as contact resistance, color, ductility, coefficient of friction, adhesion, adhesive strength or temperature resistance. The advantage of electroplating lies in being able to achieve all these properties cost-effectively, ecologically and upscalable to industrial level. We identify the properties required for the respective task and create them on our customers' components.

Layers and processes

To achieve these properties, a variety of different processes are used in industry. Based on years of experience, we have expertise in all the relevant areas, such as tribology with hard chrome plating, the deposition of nickel alloys including electroless nickel plating or cathodic corrosion protection with zinc plating or the deposition of zinc alloys, especially zinc-nickel. But we also focus on decorative processes such as copper plating, nickel plating and chrome plating. Special processes include those used to achieve specific electrical properties in the fields of silver plating, gold plating and tin plating. The surface treatment of light metals by anodizing, i.e. the deposition of anodized layers, and special electroplating processes, for example electropolishing or electroforming, are further areas of expertise. In addition to refining metal substrates, plating on plastics (POP) is also part of our service portfolio.

Our range of services

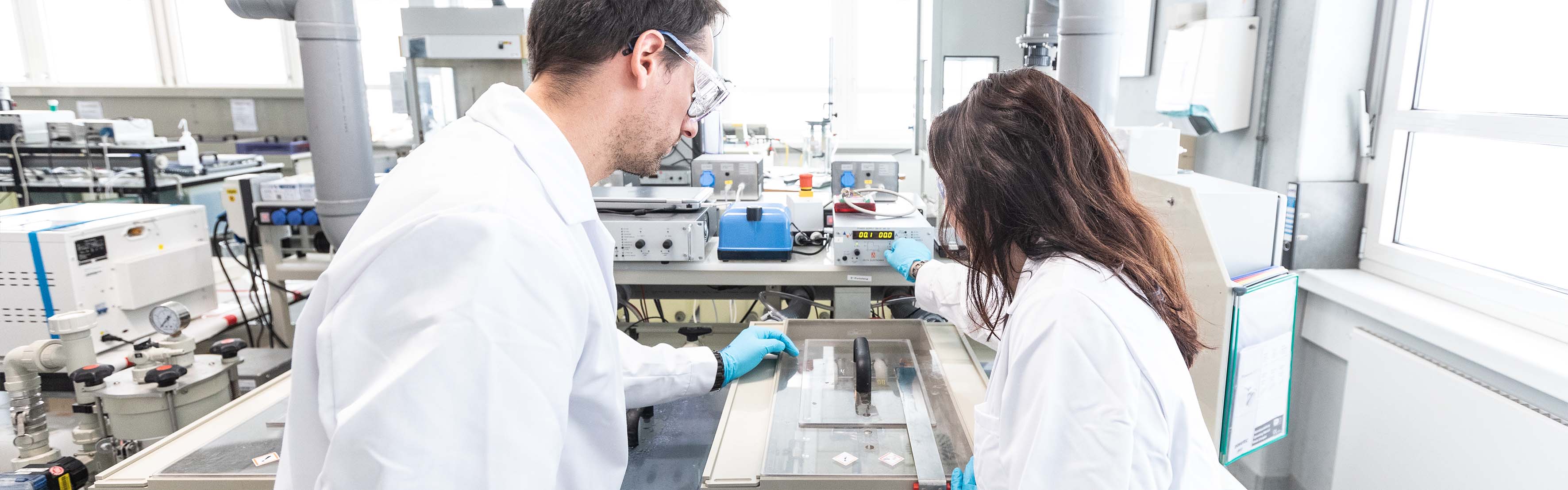

With regard to the above-mentioned processes, we assist our customers in a number of ways to further develop, modify or redevelop the respective processes. Typical types of projects include preliminary studies and feasibility studies in preparation for development projects, as well as carrying out the development projects themselves right up to upscaling them to industrial level.

Anodizing

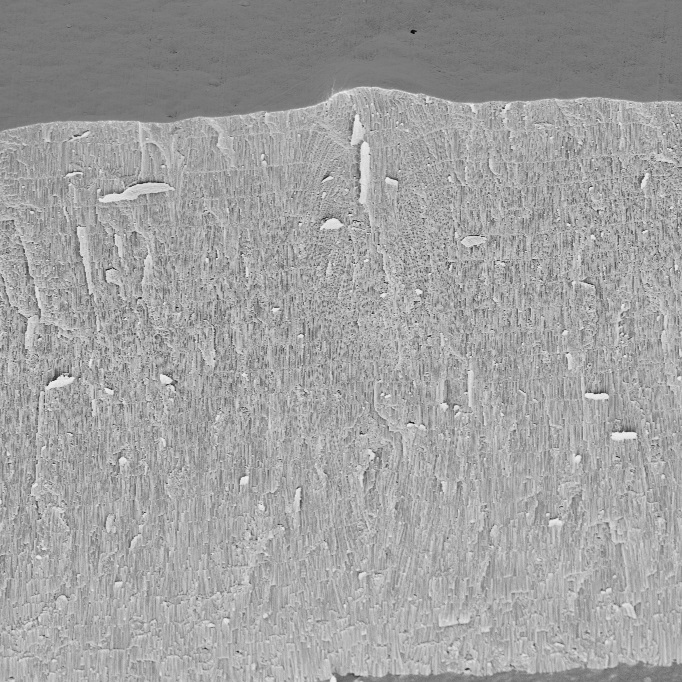

Anodization processes are commonly known as eloxal (electrolytic oxidization of aluminium) processes. In this “reverse” electroplating process - the component is connected as an anode - the surface is coated with an oxide layer. Besides aluminium, metals such as magnesium and titanium can also be used. In such processes, the layer properties are inevitably dependent not only on process parameters, but also on the composition and homogeneity of the base material.

We develop processes to specifically modify properties such as porosity, wear resistance and color. This is linked to plant design when it comes to industrial implementation. Plasma chemical anodizing processes are also taken into account.

Due to the necessary high bath voltages coupled with low electrolyte temperatures, energy requirements are an important issue in anodizing processes. In the Ökoxal project, for example, we succeeded in reducing process energy requirements by over 40 percent. This can only be achieved if interdisciplinary expertise from process and plant engineering come together in projects.

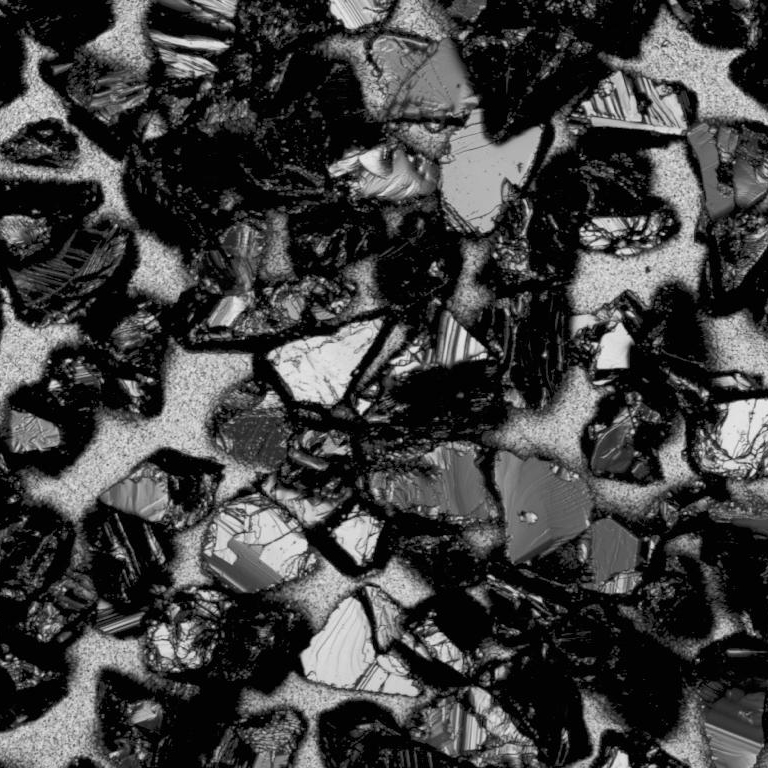

Dispersion deposition

Dispersion deposition is the selective integration of foreign substances into electroplated layers. The metal layer serves as a matrix for integrating particles with diverse attribute profiles. The particles used are insoluble in electroplating electrolytes and have a diameter of a few nanometers up to 0.5 mm. The integrated particles can be anything from hard materials to dry lubricants. Even encapsulated liquids can be incorporated into metal layers.

The controlled addition of particles enables the layer system to be specifically modified to suit to the respective requirements and thus open up new application possibilities.

Integrating a dry lubricant gives a layer enhanced gliding properties and may even eliminate the need for additional lubrication of the system in some cases.

By incorporating liquid-filled nano- and microcapsules into the metal matrix, active ingredients such as lubricants or corrosion inhibitors can be specifically incorporated into a metal layer. When the capsules are subjected to chemical or mechanical stress, these substances are released and start taking effect. Electroplated layers can thus prevent systems from running dry or ensure that damaged surfaces are still resistant to corrosion.

Hard materials such as diamond are usually embedded in a metallic matrix if a part needs to be abrasive, for example drills, cutting inserts and dressing tools. The service life of components can also be extended. By using electrolytes that are specifically adapted to the customer’s circumstances, the performance of the layer can be significantly improved. The main aspects to be considered are residual layer stress, the defined use of wetting agents and optimized particle integration.

Conventional metal deposition

Copper, nickel, chrome, zinc and precious metals are typical examples of materials used in electroplating. They have been implemented in various forms for many years. However, even these commonly-used metals need to be modified from time to time in order to meet new demands. This is especially the case if products are required to display certain functional properties, which may be highly specific to the application concerned. For this reason, we have made it our goal to adapt electrolytes and processes to our customers’ needs so that they can improve the quality of their products. After all, electroplating is one of the most common technologies used to manufacture products fulfilling the highest quality standards.

Electrolytes and processes can be modified in different ways. Innumerable variations are attained through the interaction of current density and temperature as process parameters combined with electrolytes from inorganic base elements and organic additives. These variations can be adjusted in many ways to obtain the desired layering properties. At the same time, broad product diversity means that many process parameters in industrial manufacturing have to be monitored and kept within the respective process window. Therefore, when developing electrolytes and processes, process windows need to be scaled to industrial productions. Process control measures, such as chemical analysis, also have to be implemented. Our expertise in developing electroplating processes ranges from conventional metal deposition through chemical deposition right up to anodizing processes. Developments are supported by an excellently-equipped infrastructure, including our very own process development platforms.

Alloy deposition

Binary or ternary alloys are used in industry for both decorative and technical applications. Intensive development work is currently being carried out subject to new demands regarding attribute profiles and bans on various substances. The advantage of alloy layers is that their properties can be adjusted highly specifically by modifying their composition, thus making them suitable for a wide range of uses.

Alloy electrolytes are generally extremely complex and need to be applied within a defined process window in order to achieve a consistent composition. For this reason, when developing alloy layers, it is essential to consider the industrial application and the corresponding process windows right from the outset, otherwise it will not be possible to implement a technical solution.

One of the focuses of our current work is on developing alloy layers that are subjected to extreme corrosive and tribological stress, in particular layers for bearings in seawater power plants. A key prerequisite for use in seawater is a layer that is as uniform as possible without the formation of any weak spots during the deposition process. To meet this requirement, we have invented and implemented a special machine for plating the full surface of bearings in a seamless process.

An important aspect to consider when developing alloy layers is the versatility of the application. Due to the different alloy compositions that can be specifically created and their respective attribute profiles, the areas of application of alloy layers are endless. Our experience in process development and in designing and planning electroplating systems enables us to develop alloy layers tailored exactly to your requirements.