Accuracy enhancement for robotic systems

Tabbed contents

Expertise

Zero-defects, top-quality production results can only be achieved if all system components interact precisely. Furthermore, in order to carry out targeted manipulation using industrial robots, the exact position of components in the robot cell must be known. Especially the position of tools and sensors located at the robot's end effector needs to be accurately identified in order to move the tool on a defined path and execute the process as accurately as possible.

Time and again, however, processes fail to meet these high accuracy requirements. Experience shows that these reliability problems are due to the fact that the robot cell is not calibrated accurately. Fraunhofer IPA offers tailor-made solutions for this. With our state-of-the-art measuring systems and robotics expertise, we pinpoint sources of error and help you optimize your equipment. In addition, our expert knowledge combined with our first-class facilities enables you to calibrate your robot components with a high degree of accuracy, thus improving the reliability and quality of your processes. We would be pleased to advise you on site or in our research laboratories.

Services

- Measuring your robot cell and robot tools with our own measuring equipment and determining exact parameter sets for cell and tool calibration

- Calibrating integrated sensor technology: 3D, 2D or 1D measuring systems

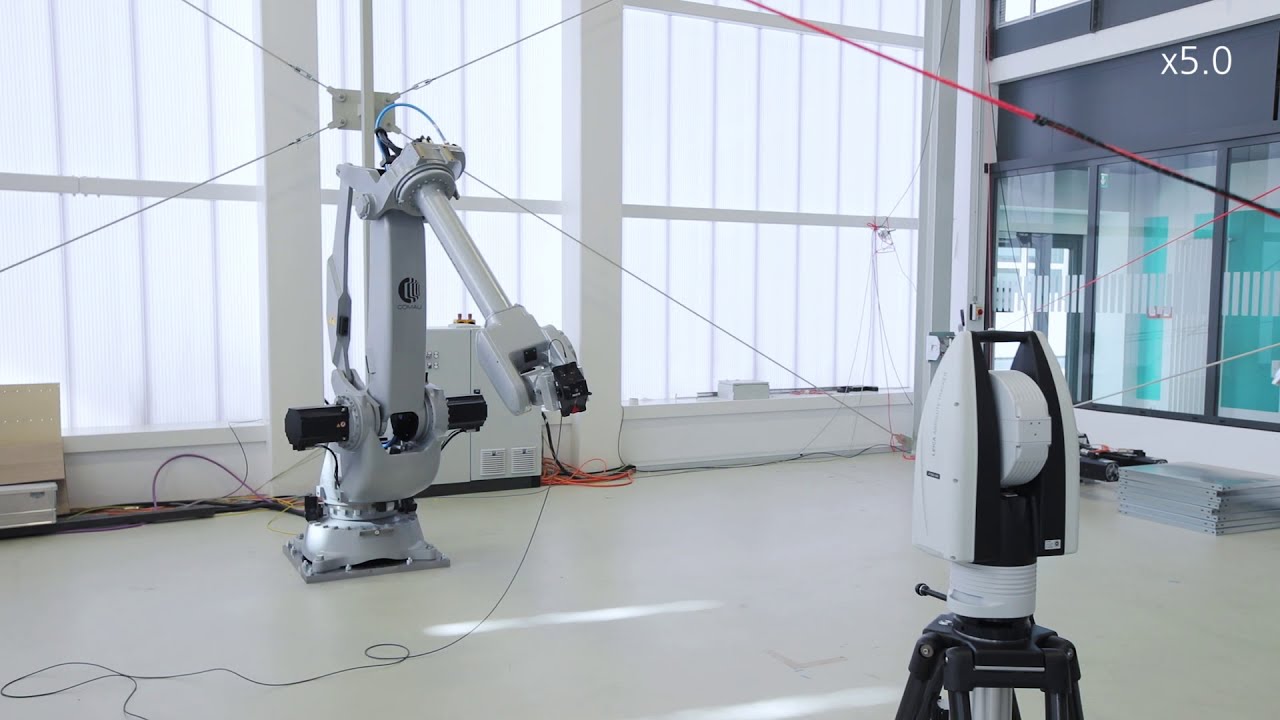

- Determining the absolute, repeat and path accuracy of industrial robots with the Leica Absolute Laser Tracker, which can measure positions at a sampling rate of 1000 Hertz and with an accuracy of 15 µm

- Investigating the impact of external influences on robot performance, for example ambient temperature, vibration of the machine base and upstream processes

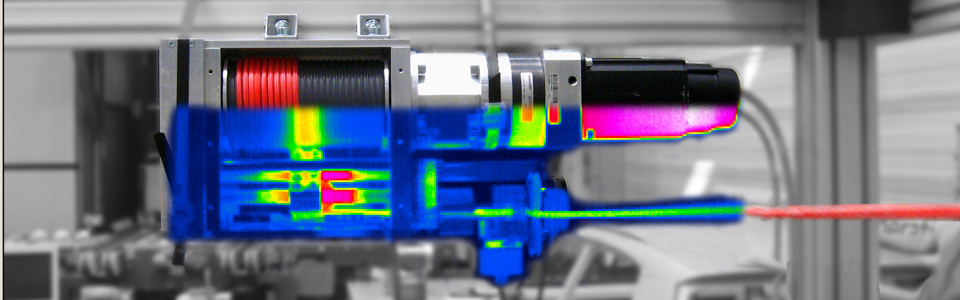

- Measuring the thermal response of assemblies and automation components with a thermographic camera

- Measuring and calibrating portal robots and special kinematics

- Designing calibration systems tailored to your application, for example for deburring, milling, quality inspection and all high-precision and sensor-supported robot processes

Measurement of industry robots to improve precision