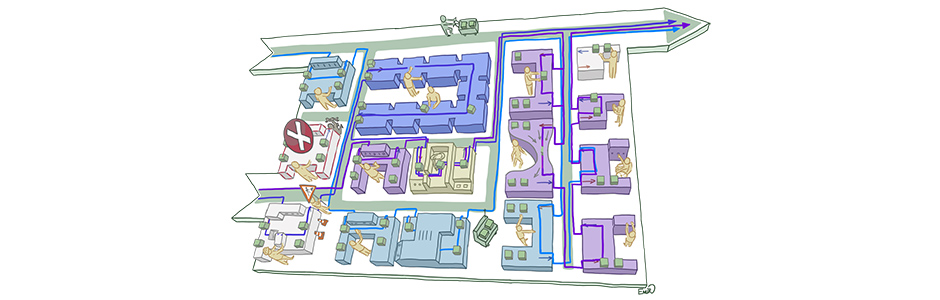

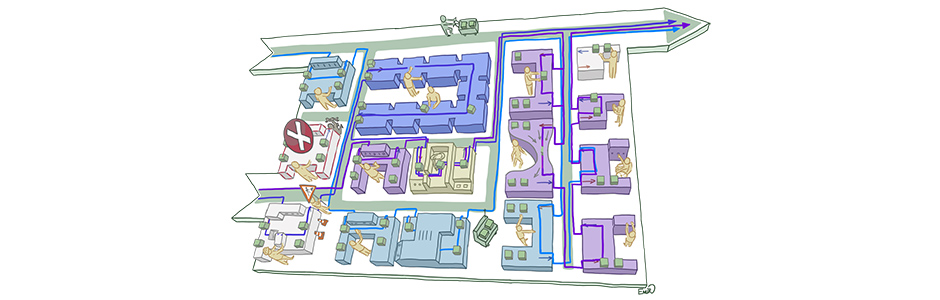

Flexible and productive: matrix production

To meet the challenges of the market, the production system must be designed in line with requirements. On the hardware side, matrix production focuses on flexibly-linked process modules that are planned according to the processes, capacity and resources. Intelligent control makes use of the structural degrees of freedom for variant-specific order flows - right down to batch size 1!

The advantages:

- Creates new automation potential

- Shorter waiting times for employees and resources

- Higher variant flexibility and low-waste mapping of high variant diversity

- Up/down-scaling in small steps

- Less susceptibility to disruptions in the event of resource shortages or supply chain upsets

- Heterogeneous employee development (short training period at the beginning, varied work distribution for skilled workers)

A matrix production can be used at division and segment level. The priority is to increase flexibility where it is needed, thus improving the overall system.

In many applications, we see that existing concepts and solutions are reaching their limits and that there is a need to change to flexible and resilient systems. These must always be aligned with requirements to ensure a balance between benefit and effort. We help you to strike this balance and to respond to the challenges of the VUCA world on the production side.

The range of services offered by the Automotive Business Unit covers a broad spectrum of processes for designing systems and enabling hardware and software to meet new challenges.

In detail, these are:

- Matrix production system design

- Classic and AI methods for customer-specific control and order management

- Tapping new automation potential

- Adaptive building services and flexible energy supply

- Process assurance in multi-variant production

- Consistent use of data

- Empowering employees to perform physically challenging processes