Development and optimization of machines and tools for cutting and sawing processes

Sawing processes are a vital part of almost every manufacturing chain and play an essential role in machining a wide variety of materials. These processes require highly specialized tools and machines, which are often underestimated. We support you in optimizing this crucial step of your production line or in advancing your tool design. Our expertise ranges from tool design and tool body construction to production steps such as brazing, grinding, and micro-edge shaping. We support you in validating tool performance for your specific use case.

Case Study: Internal Cooling for Circular Saw Blades

In machining operations, it is crucial that the cutting edge is properly wetted with coolant. This is not always possible with conventional circular saw blades and standard cooling methods. Together with industrial partners, we developed the world’s first internally cooled circular saw blade. This ensured continuous cooling of the cutting edge throughout the entire process, significantly improving the cutting performance.

Case Study: OneShot – A Combined Sawing and Deburring Tool

Even with the most advanced tools and processes, fully burr-free cuts cannot always be achieved—though this would be highly desirable to eliminate downstream operations and boost productivity. The OneShot system, combining a circular saw blade and a grinding tool in one, provides a solution: It enables simultaneous sawing and deburring of aluminum profiles in a single step.

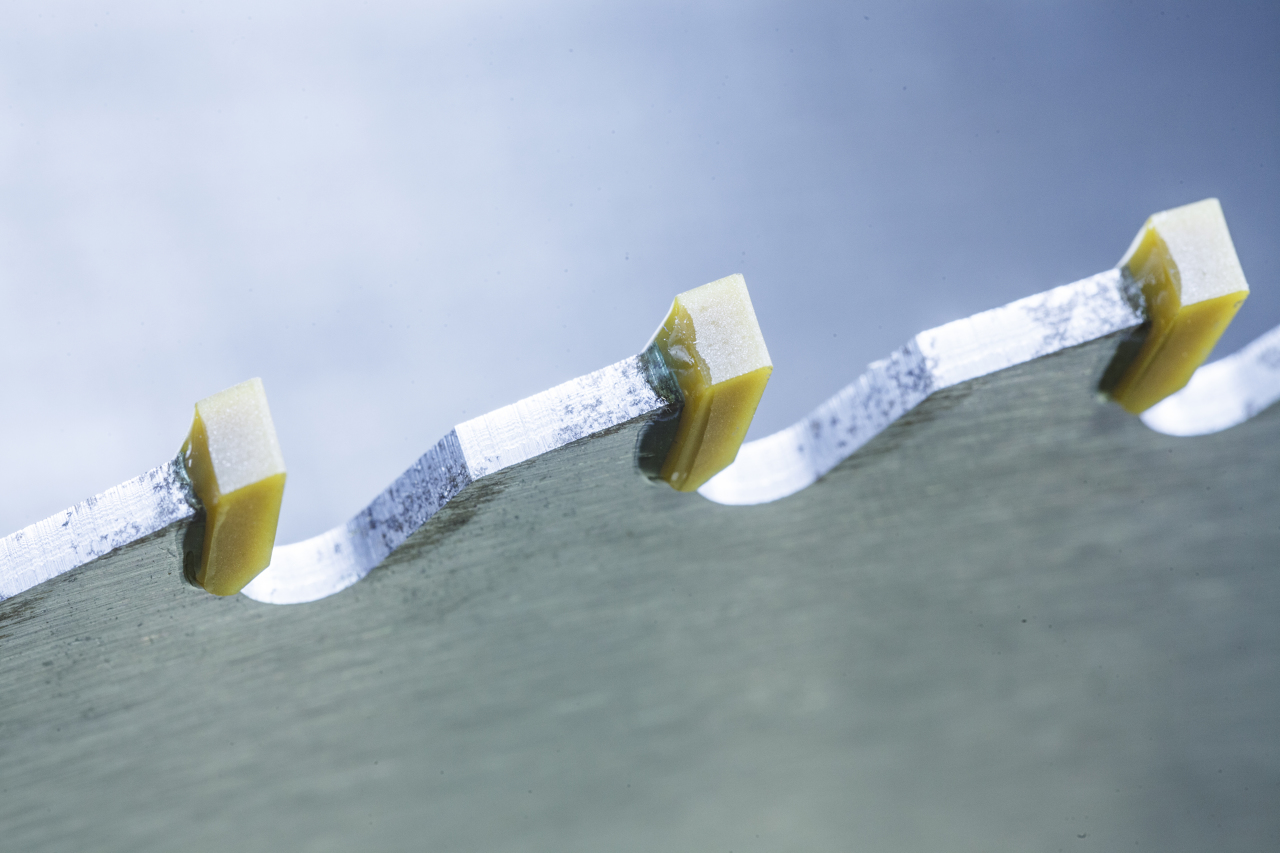

Case Study: Bonding Ceramic Circular Saw Blades

The productivity of circular saw blades cannot always be increased through geometry optimization alone. Switching to alternative cutting materials such as ceramics offers another path forward. However, ceramic tools must be bonded rather than brazed, introducing challenges such as surface preparation, long-term durability, and automated manufacturing. Once these were overcome, the ceramic saw blades showed a significant increase in productivity—while eliminating the need for expensive silver brazing alloys.