Here we show a small selection of our current and successfully completed research and industrial projects.

Please note that many of our references are subject to secrecy and therefore can not be displayed.

Please do not hesitate to contact our departments directly if you can not find your task.

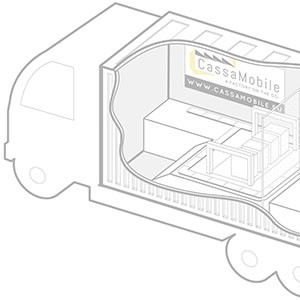

CassaMobile: the mobile, modular and smart networked minifab in a container.

more info