Peripheral Systems and Energy Efficiency

For both precise and productive as well as cost-effective and safe sawing processes, the tool itself is only part of the equation. Peripheral systems also play a crucial role. These include clamping systems, chip removal, cooling and lubrication systems, extraction technology, and more. Even simple monitoring systems can be considered part of the process periphery—especially when integrated into comprehensive process monitoring, such as energy monitoring on legacy equipment without OPC-UA interfaces.

We support you in developing, optimizing, selecting, integrating, and validating peripheral systems tailored to your cutting process.

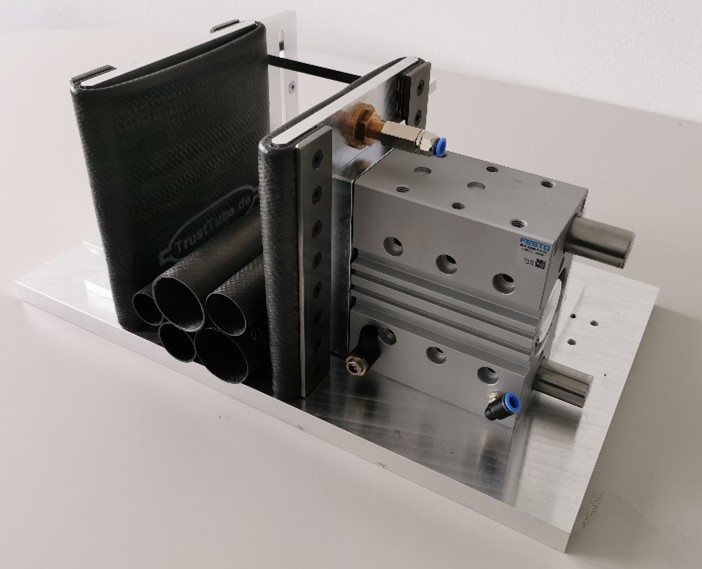

Case Study: Adaptive Clamping System for Thin-Walled Tubes

For high-throughput processes, it can be beneficial to clamp and process multiple tubes in a disordered (chaotic) arrangement. Conventional systems for this purpose are often complex, customized, and expensive. To overcome this, we developed a flexible tube clamping system using air cushions, allowing for the chaotic positioning and simultaneous cutting of tubes—without the need for rigid clamping mechanisms.

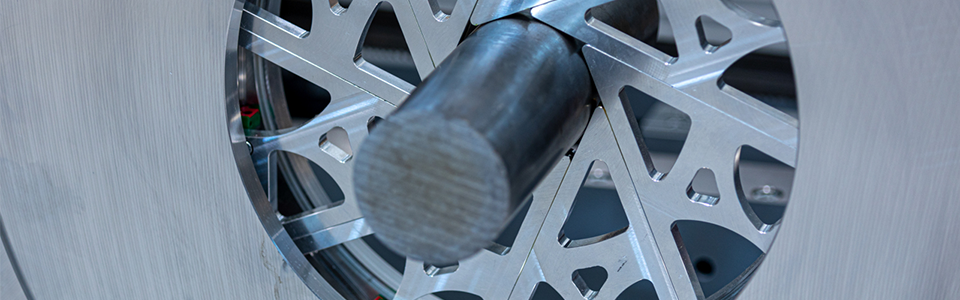

Case Study: Extraction Technology

Many materials release hazardous or even explosive dusts during processing. This is not limited to composites like CFRP and GFRP but also includes certain wood types. The health and safety risks posed by such dusts are often underestimated. In several research projects, we are continuously improving dust extraction systems through experimental validation and simulation—ensuring both safety and performance.

Case Study: Energy and Productivity Monitoring

In many SMEs, productivity and energy use are not sufficiently tracked—not due to a lack of awareness, but because older machinery lacks built-in monitoring capabilities. In several projects, we have developed retrofittable sensor solutions that allow for the monitoring, evaluation, and visualization of energy and productivity data, regardless of the machine’s age. This creates new opportunities to identify and realize process improvements.