Solutions for post-processing, including surface finishing and deburring

Efficient post-processing steps are still often overlooked in many companies – despite their significant potential for optimization. From various automation options to innovative processing technologies, we support you with our expertise in post-processing and surface finishing to help you improve and further develop your processes.

Case Study: Post-Processing of Additively Manufactured Metal Parts

Additively manufactured metal components often show process-related “stair-stepping” on the surface. This results in rough finishes that are usually post-processed manually – especially in small batch sizes and high part variety. By using vibratory finishing techniques, manual effort can be significantly reduced while achieving high surface quality and process stability, even on complex inner and outer surfaces.

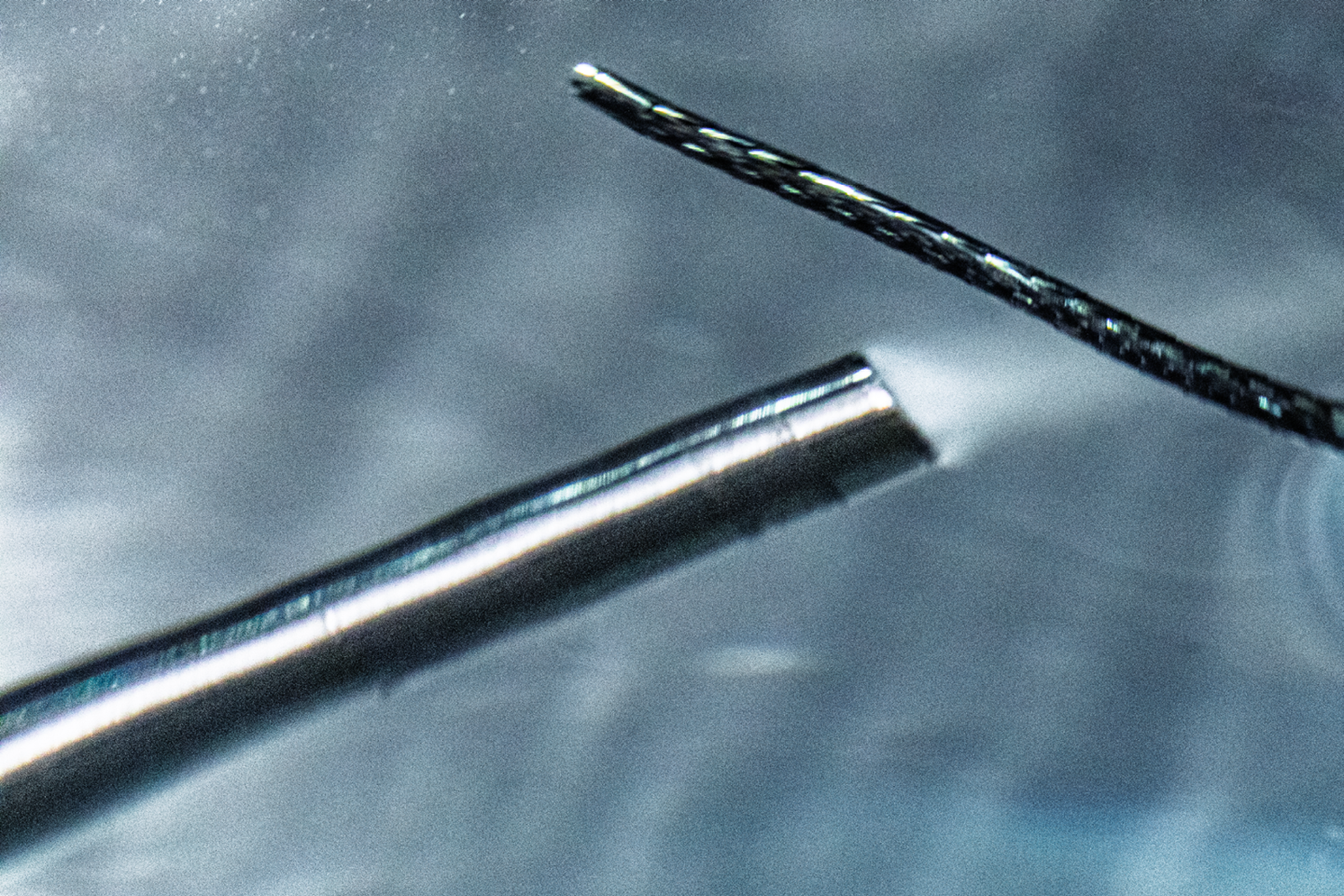

Case Study: Ultrasonic Surface Finishing for Thin-Walled Structures

Thin-walled structures are often cut using lasers, which can cause slag and burrs. These are difficult to remove with conventional methods without damaging the parts or requiring additional cleaning steps. Ultrasonic deburring offers an alternative. Through cavitation effects, burrs can be removed and the components simultaneously cleaned – a particularly effective approach for delicate medical parts such as stents, where we have already demonstrated feasibility.

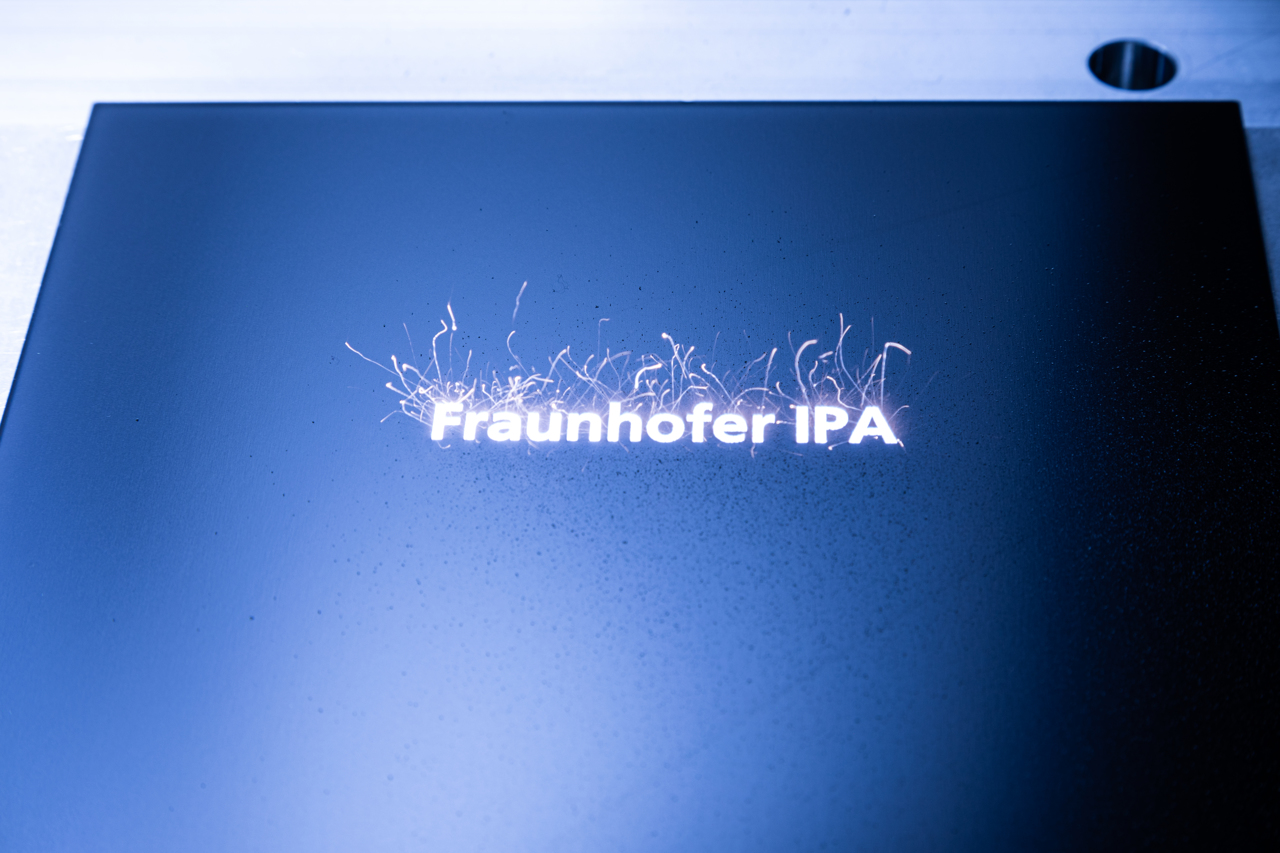

Case Study: Surface Functionalization for Adhesive Bonding

The surface condition of joining parts is critical for adhesive bonding. Surfaces must be clean and promote both mechanical and specific adhesion. Common methods such as grinding or blasting are often not reproducible and only enhance mechanical adhesion, which may also contaminate the surface again. Laser technology provides a more effective solution: It can clean and activate surfaces in one step, creating chemically active bonding zones that significantly increase joint strength. This applies even to challenging materials like carbides or ceramics.