Validation of innovative cutting processes

Cutting processes are indispensable in industry: They are used both in production for manufacturing new products and during disassembly processes at the end of a product’s lifecycle. Thanks to our extensive and diverse machinery — ranging from classic circular saws to advanced ultrasonic technology — we provide independent, process-neutral consulting for any task, conduct trial cuts, and calculate the economic feasibility of new processes for you.

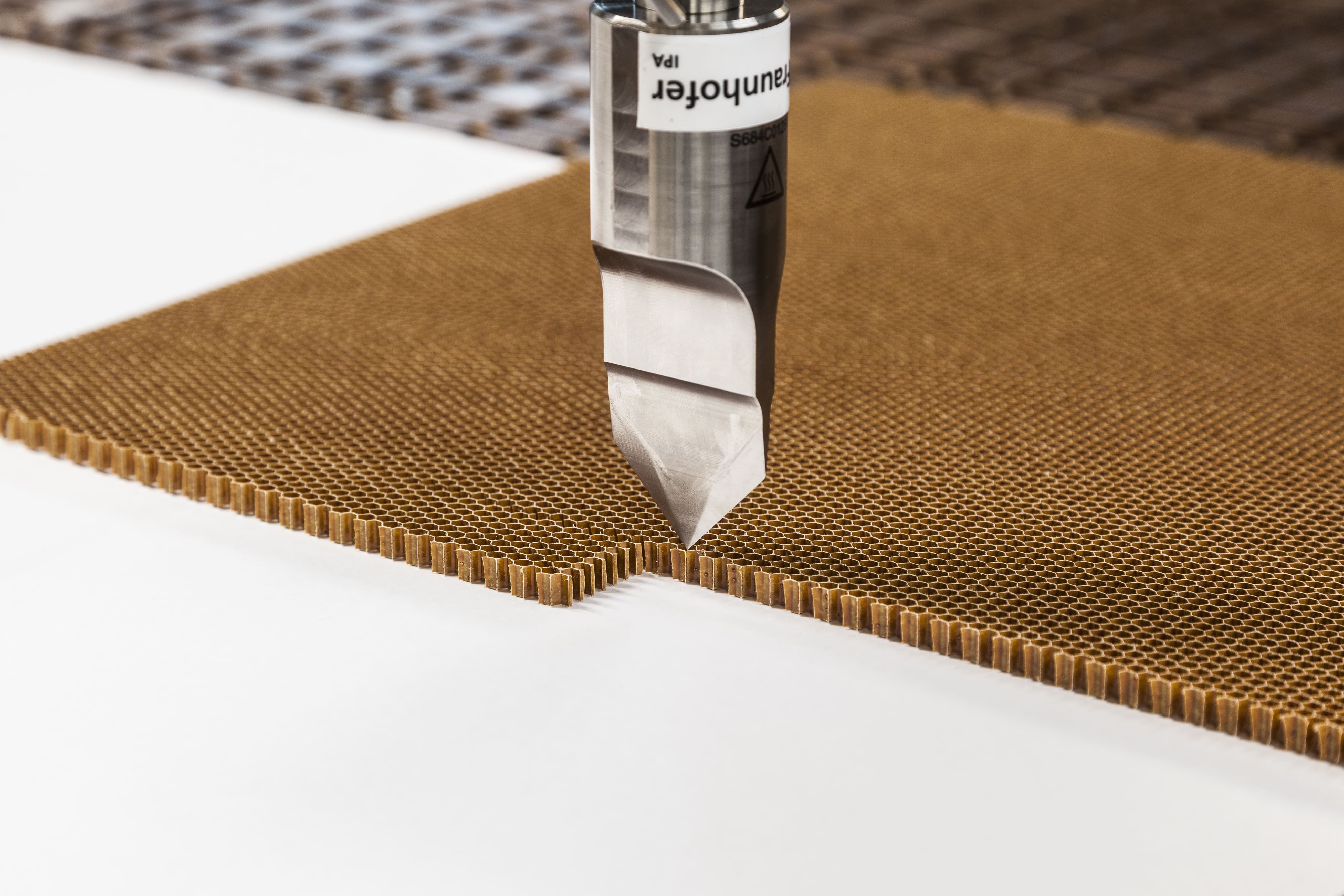

Case Study: Ultrasonic cutting of honeycomb structures

Honeycombs for sandwich components are difficult to process using conventional cutting methods. Traditional cutting often causes crushing and damages the honeycomb, which can render the final sandwich structures unusable. Through targeted development and process optimization, ultrasonic cutting has significantly reduced these defects.

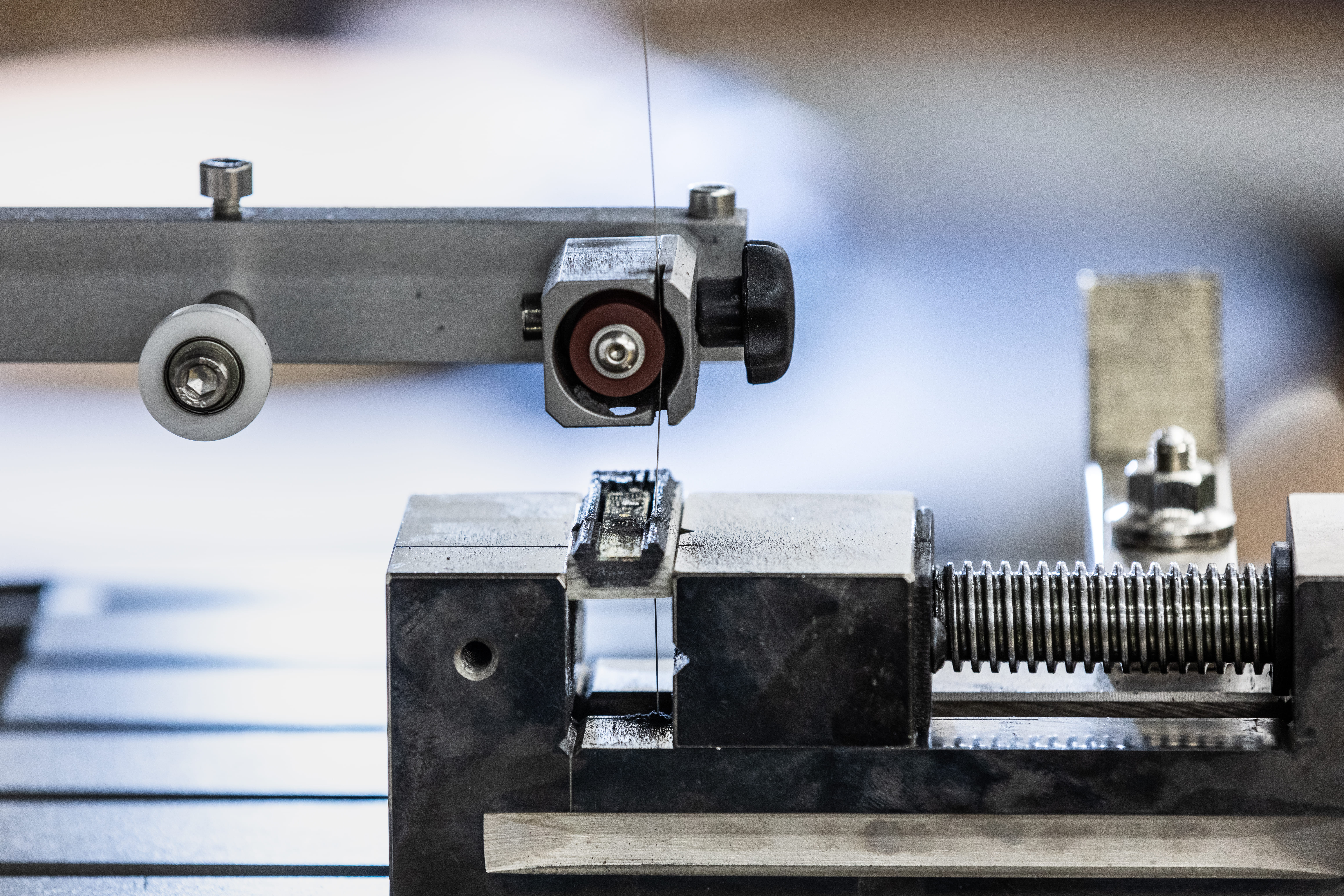

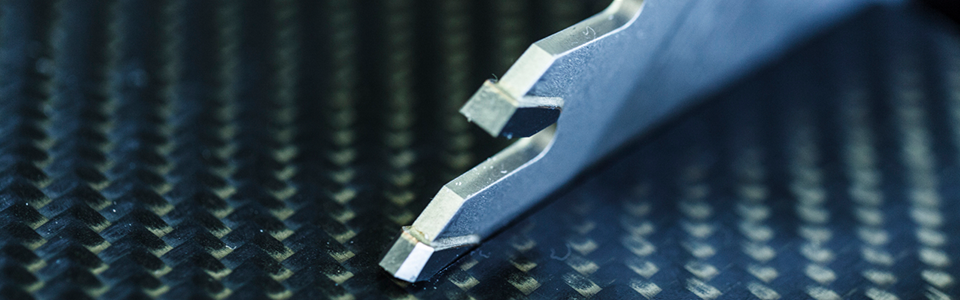

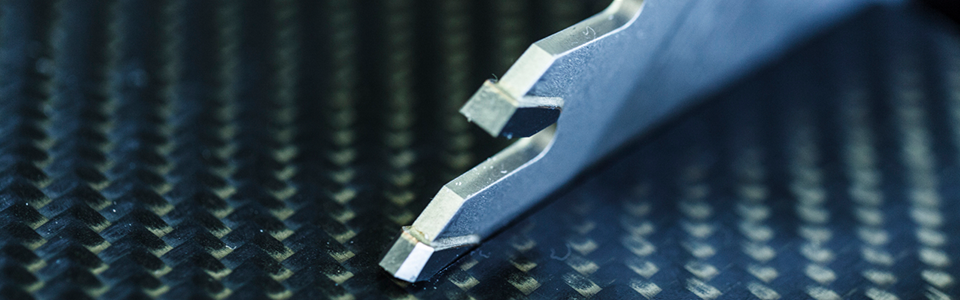

Case Study: Wire sawing of additively manufactured metal parts

Additive manufacturing of metal parts relies on support structures during printing, which are often removed manually afterwards. This manual removal wastes a lot of labor and time. Currently, we are investigating in several research projects how to automate the separation of support structures. With proper parameter selection, it is possible to perform the cutting and surface finishing in a single step.

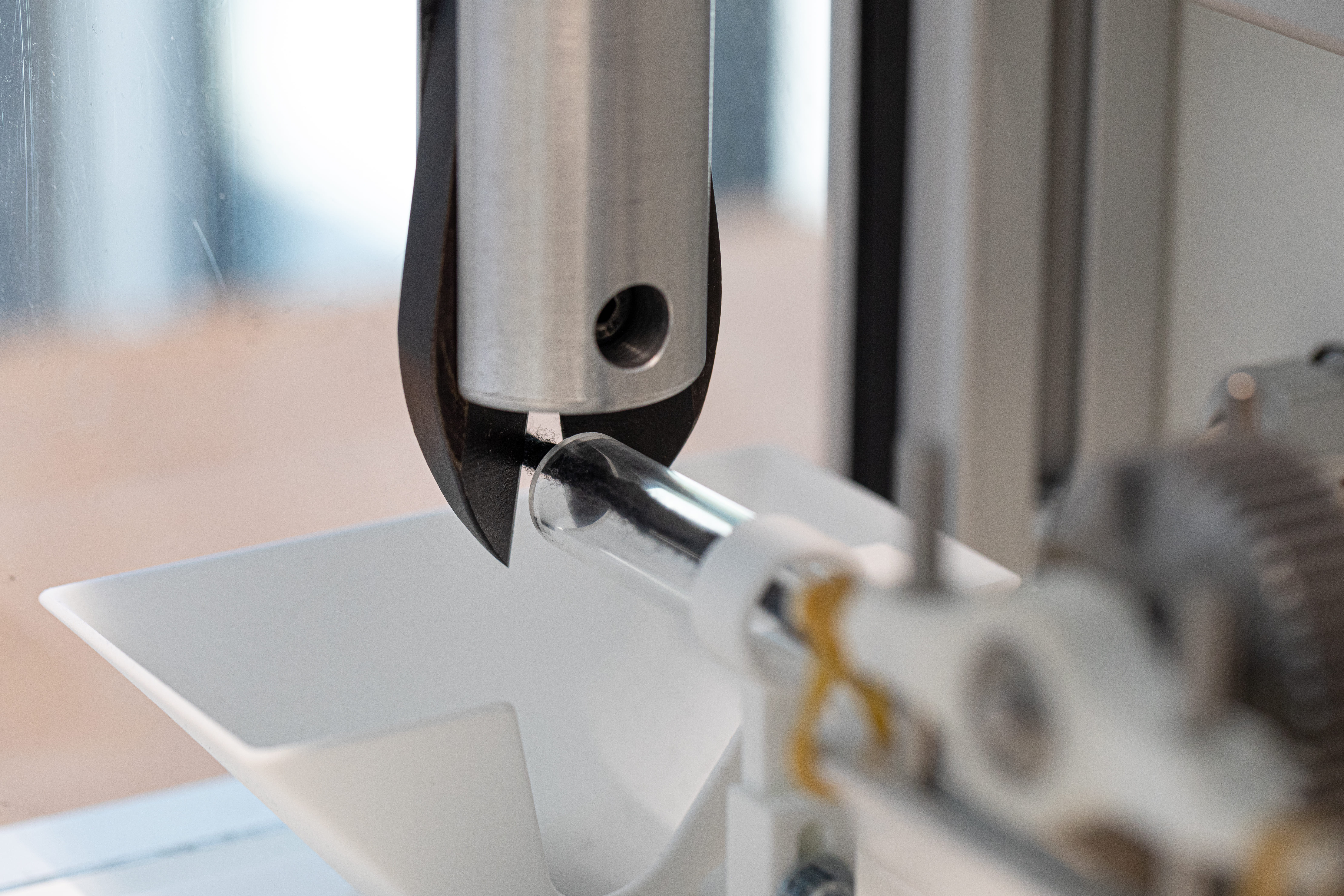

Case study: Cable-cutting technology for battery disassembly

Battery disassembly faces various challenges, one of which is selecting a suitable cutting method for cable connections. Within the DeMoBat project, an automated cable cutting technique was developed, tested, and evaluated for its performance.