Clamping and handling technology

The process of machining workpieces requires clamping and handling technology that is system-specific so that workpieces for the machine tool can be correctly positioned and secured in place, and securely clamped throughout the machining process. We will help you to select appropriate clamping and handling equipment by working with you to identify the process-related requirements. Through a requirements analysis, we will develop and implement appropriate clamping and handling concepts, including the optimization of machining steps and their sequence.

Case study — development of 3D-printed, highly integrative clamping templates for CFRP components

The “CFK-Complete” research project involved the production of a prototype of a clamping template with integrated functions for post-machining of components made from carbon-fiber-reinforced plastics. Through the combined use of additive and subtractive manufacturing methods, topology optimization and a high level of functional integration, it was possible to identify new approaches for the efficient production of clamping templates.

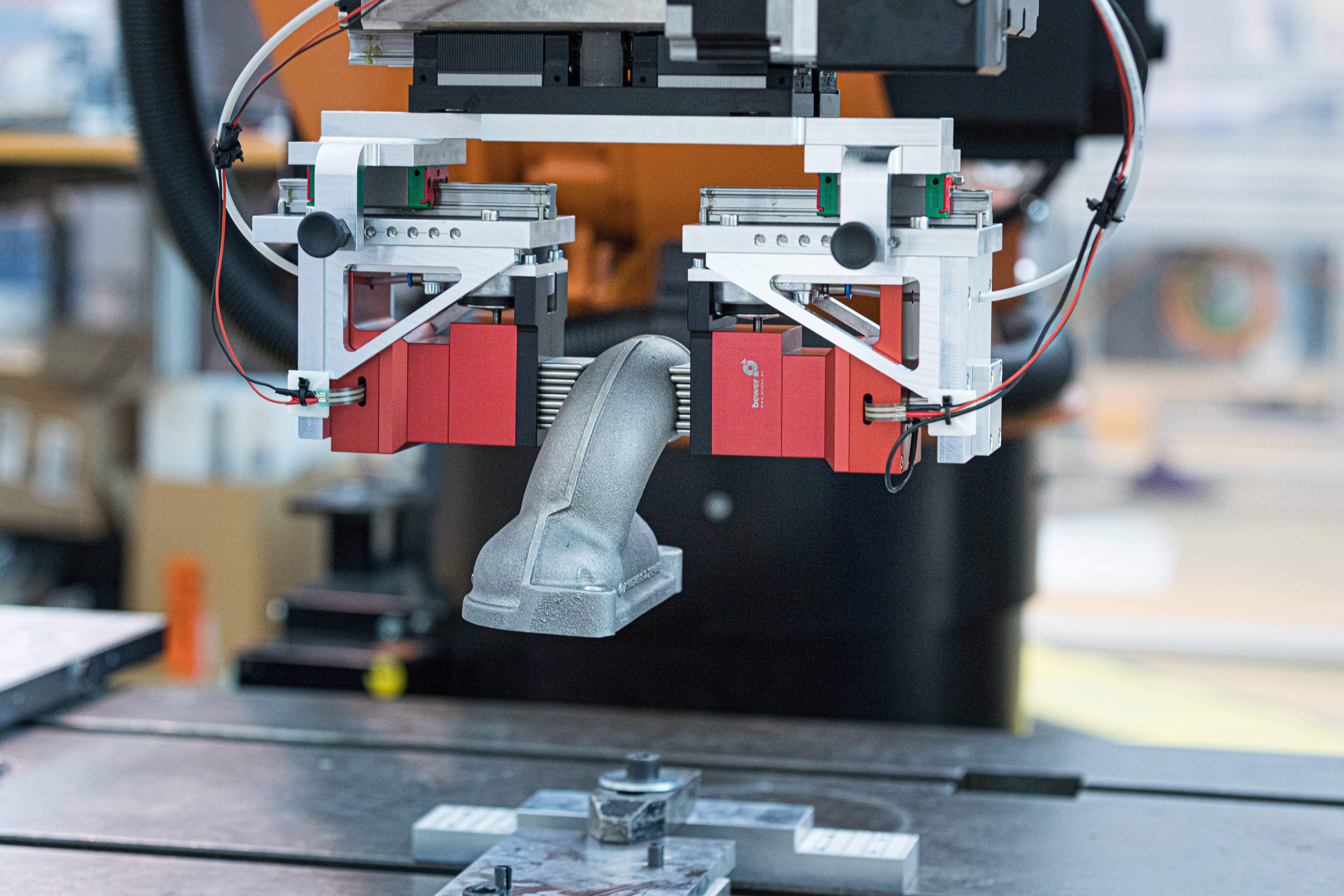

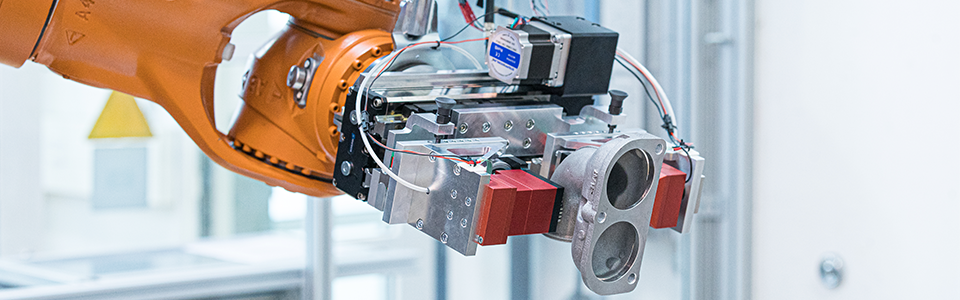

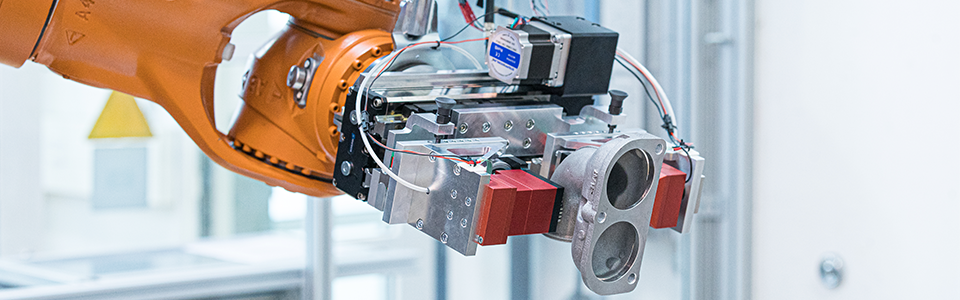

Case study — automated clamping technology for robot handling

Flexible handling technology is needed when handling a wide variety of products and components in order to avoid the work involved in changing over rigid shape grippers. Based on an existing Flexform clamping module from Christian Bewer GmbH, our experts have developed a fully automated gripping kinematics system with force monitoring. The system registers the molding of any given workpiece and locks the ram pad in place. A definable clamping force can then be applied that ensures safe component handling.

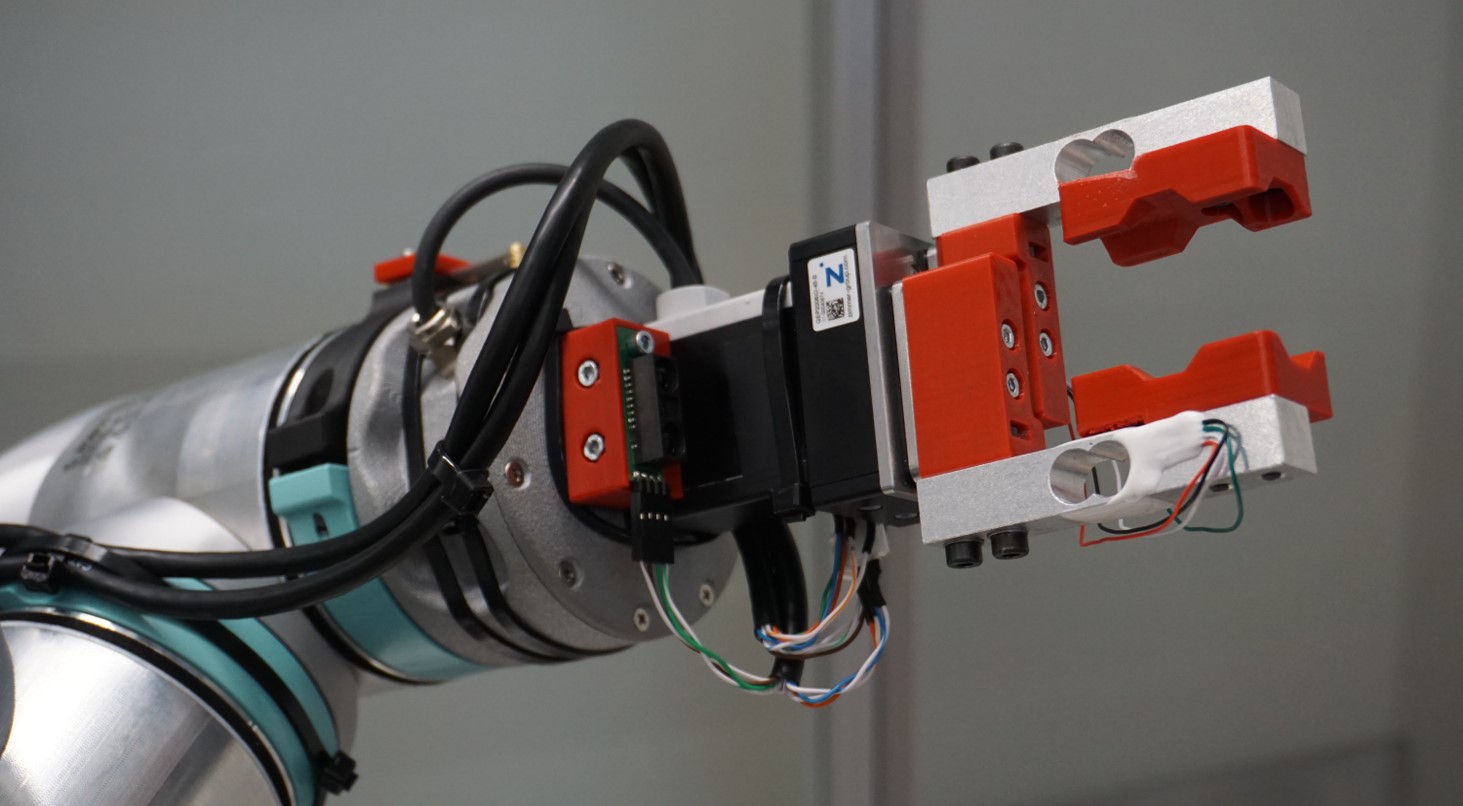

Case study — low-cost sensors for robot-supported feeding of turning and milling machines

The process of feeding turning and milling machines is a challenge when handling small batch sizes and changing components, since every handling task must be taught from scratch. As part of an industrial project with RobCo GmbH, a low-cost sensor package with retrofit capability was developed that enables automated loading and unloading of turning and milling machines.