Cutting simulation

A cutting simulation is a cost-effective method for analyzing and optimizing cutting processes. Compared to direct analysis of the actual process, which requires complex testing of the cutting process, a simulation allows a comprehensive analysis to be implemented without any physical interventions. This means the development costs and times for new tools can be reduced considerably. We offer comprehensive services in the field of cutting simulations, with the aim of optimizing efficiency in production. Using state-of-the-art simulation tools, we analyze cutting processes, identify potential improvements and help companies to reduce their production costs.

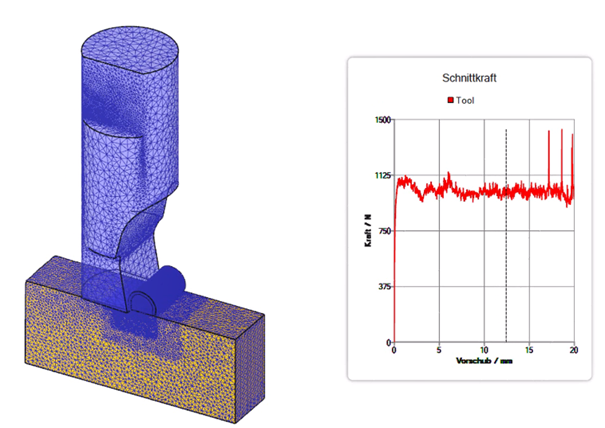

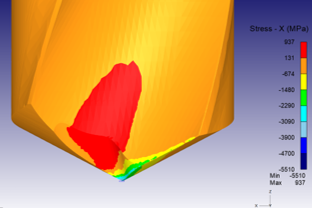

Case study: Influence of laser-applied microstructures on shaping tools

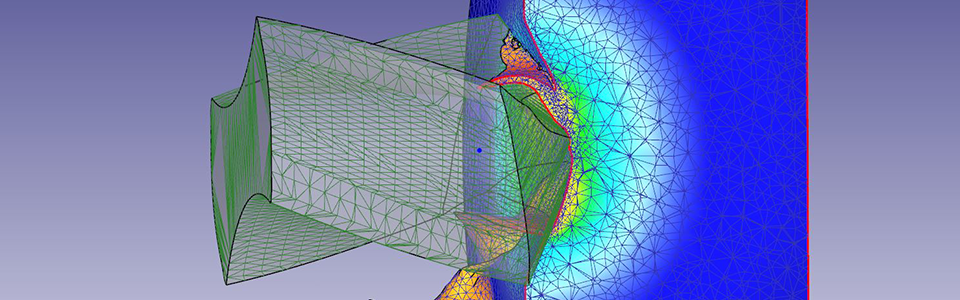

The “BionicTools” research project involved a systematic examination of the use of laser-applied microstructures on milling tools for machining aluminum. In order to simulate simplified physical environments, the initial investigations focused on the application of microstructures to planar surfaces, particularly on shaping tools. In order to reduce development times and costs, an evaluation of potential microgeometries using a finite element method (FEM) simulation was conducted before application to determine their process-optimizing properties.

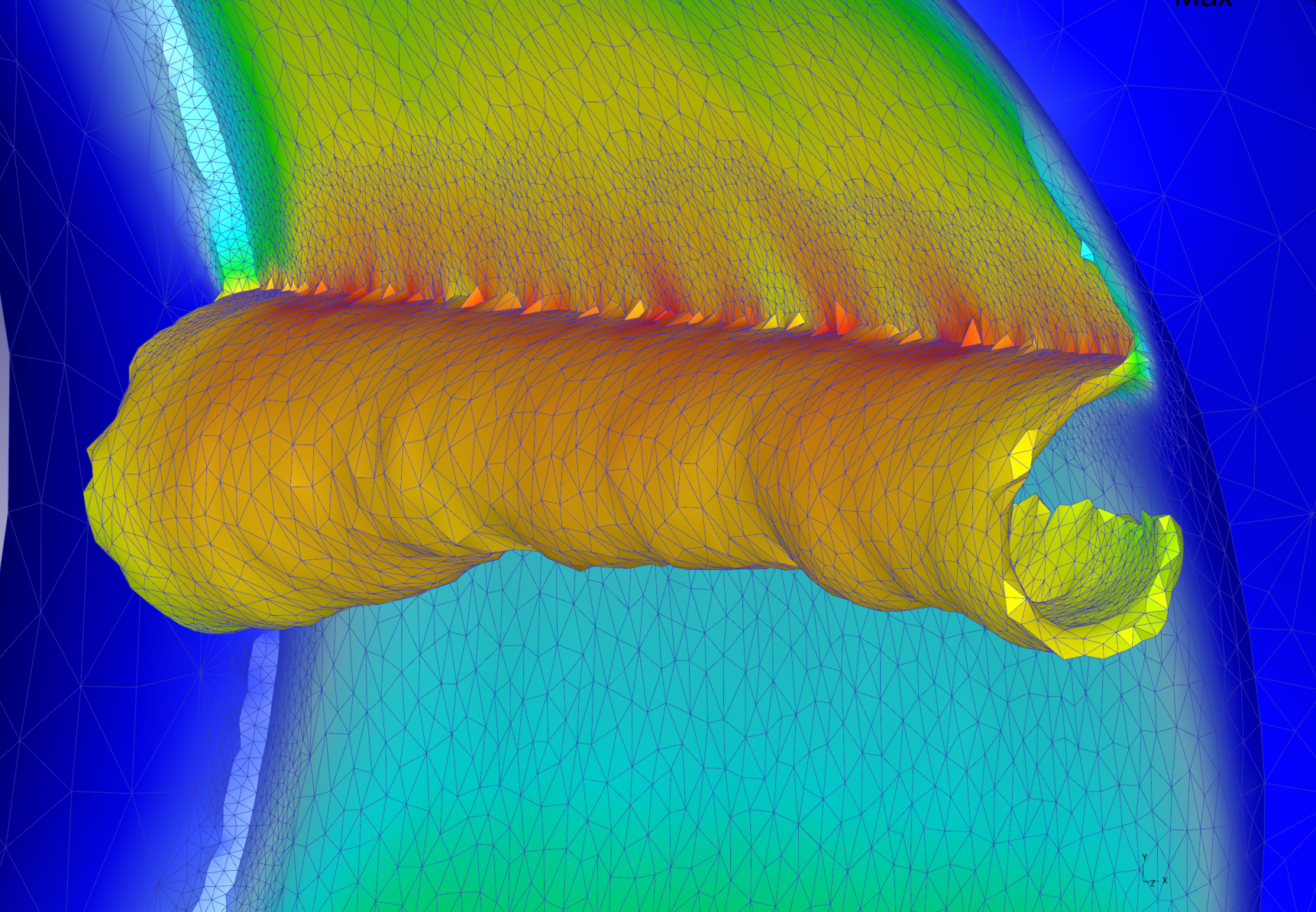

Case study: Tool development for titanium/CFRP stack machining

The process of machining laminar materials with different material layers places particular requirements on the cutting tools. As the mechanical properties of the individual layers vary significantly, specific tool geometries are required. In the “EasyDrill” research project, the displacement behavior of different drill geometries when drilling titanium-CFRP stacks was therefore analyzed using FEM simulation and an optimal tool geometry was developed.

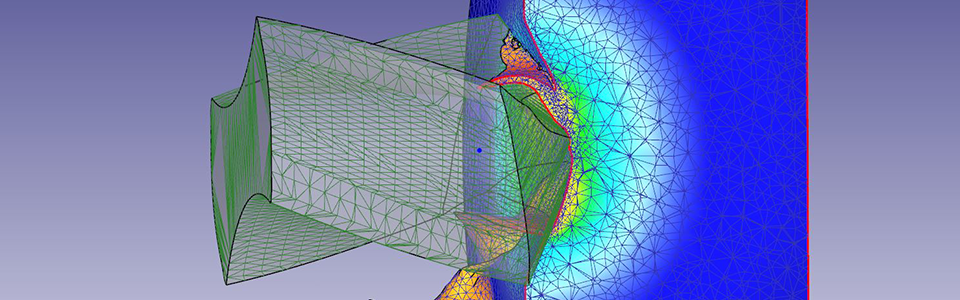

Case study: Influence of modified parameters on the process temperature

Due to the complexity of modern machining processes, even slight changes in the material, tool or cutting parameters can have a significant impact on the machining results. An industrial project examined the influence of different types of cutting edge rounding, as well as different drilling diameters and cutting parameters, on the process temperature of the tool and material in a reaming process.