Development and optimization of cutting processes

The ongoing development of cutting technologies is opening up new opportunities for optimization in every cutting process. To ensure our customers remain competitive over the long term, we develop practical solutions for turning, drilling and milling, ranging from cutting tools and machine tools to complete process chains.

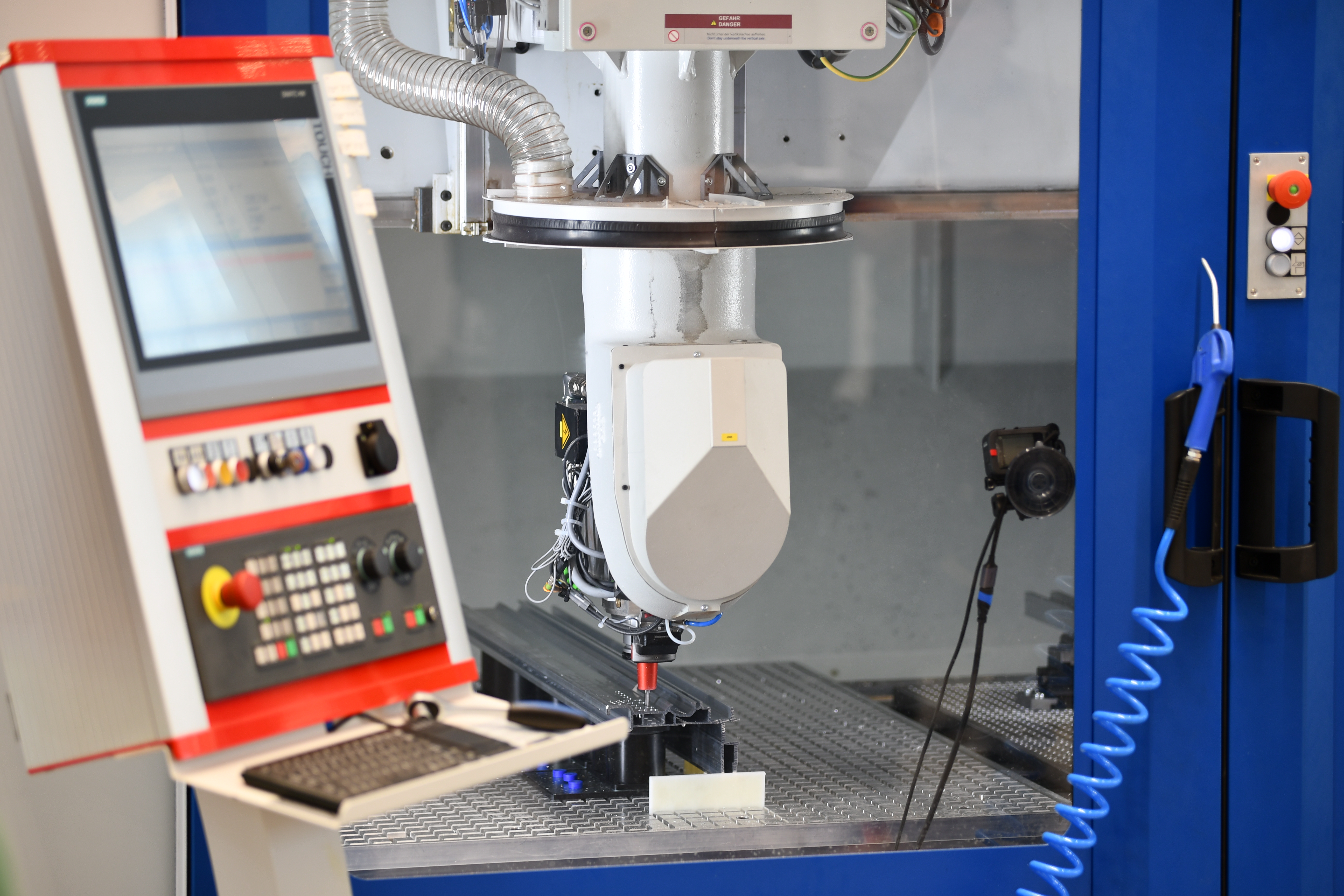

Case study — intelligent complete machining and sealing of CFRP components for large-scale series production

In the “CFK-Complete” research project, Fraunhofer IPA worked with industry partners to develop a modular machine tool that is suitable for large-scale series production and optimized for machining CFRP components. Through the integration of process modules for machining, measuring, cleaning and sealing in a single machine cycle, it was possible to create a complete machining process parallel to main time.

Case study — optimization of aluminum profile machining

The process of machining aluminum profiles was optimized together with industry partners. The analysis covered the complete process chain, from clamping and selection of appropriate tools and cutting parameters to programming and process monitoring, as well as cooling and cleaning of the machined profiles.

Case study — evaluation of a new milling tool for trimming CFRP

As part of an industrial project with the company Cruing Italy s.r.l., a new type of milling tool was examined in terms of temperature development, machining quality and tool wear and compared with a conventional end mill cutter when trimming carbon-fiber-reinforced polymers. This was used as a basis for determining optimization measures.