Robot-based hybrid manufacturing

Hybrid manufacturing combines the benefits of additive and subtractive manufacturing, enabling greater flexibility and improved material efficiency to be achieved, as well as the ability to manufacture complex geometries while maintaining optimal surface quality and dimensional accuracy.

In the field of hybrid manufacturing, we offer a wide range of solutions, including feasibility studies, the development and optimization of additive and subtractive processes and the implementation of additional processes. Through targeted analysis and individual consultations, we help our partners to optimize their production processes, reduce costs and improve the quality of their products.

Case study — development of 3D-printed, highly integrative clamping templates for CFRP components

The “CFK-Complete” research project involved the production of a prototype of a clamping template with integrated functions for post-machining of components made from carbon-fiber-reinforced plastics. Through the combined use of additive and subtractive manufacturing methods, topology optimization and a high level of functional integration, it was possible to identify new approaches for the efficient production of clamping templates.

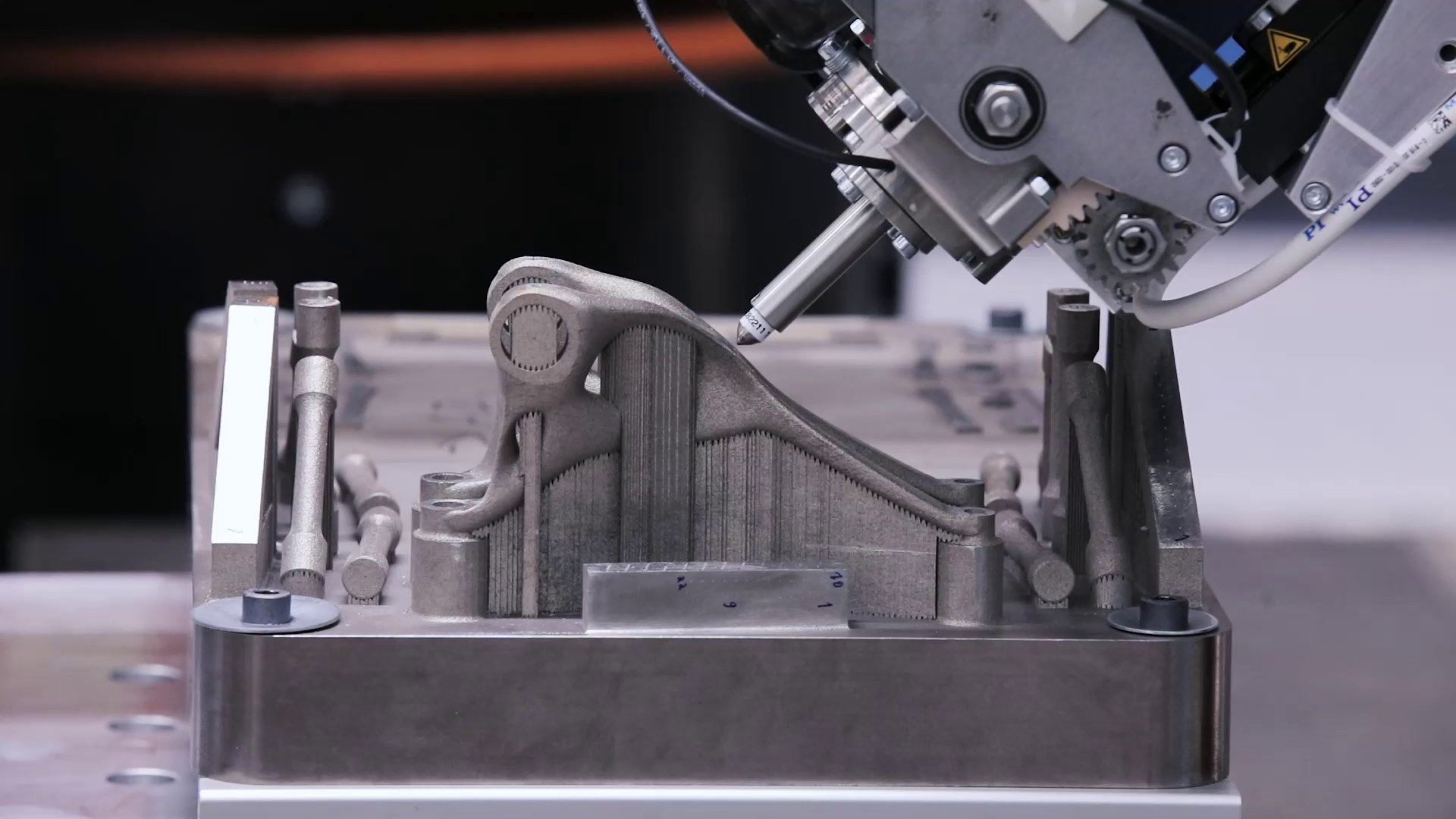

Case study — automated quality control of 3D-printed components

For safety-related components made using 3D printing, a comprehensive quality inspection is essential. In the “Enabl3D” project, an automated hardness measurement process with a six-axis industrial robot was demonstrated for Imprintec GmbH. Integration into the machining cell for post-machining and for removing the supporting structures made it possible to remove the separate measuring station and significantly reduce the process time.

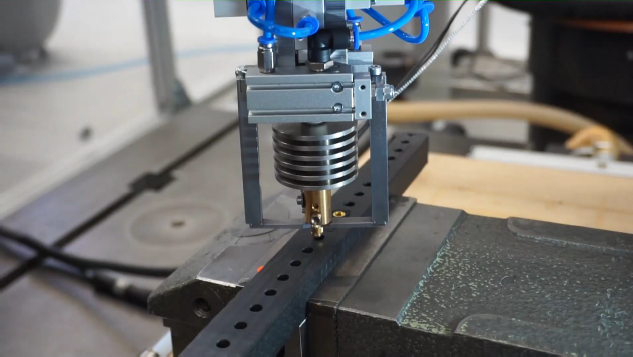

Case study — in-process insertion of threaded inserts

Additive-manufactured components often need interfaces with other components. However, inserting the thread directly into the plastic does not offer sufficient strength and resistance to wear. This is why a system has been developed that enables threaded bushes in sizes M3 to M10 to be inserted into additive-manufactured components without the need for any re-clamping. The system can be inserted into the milling spindle and the threaded bush can be inserted automatically in a defined position and alignment.