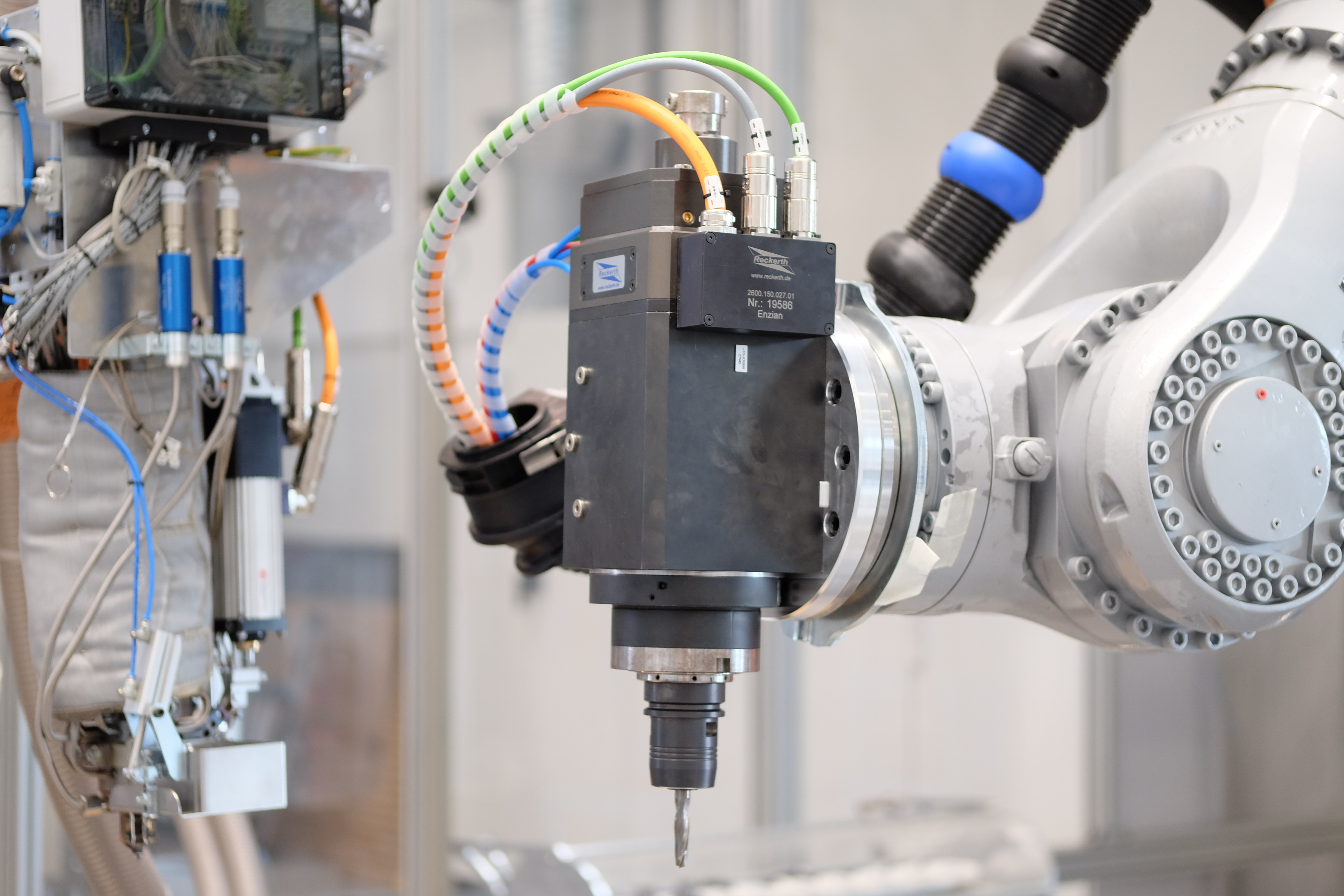

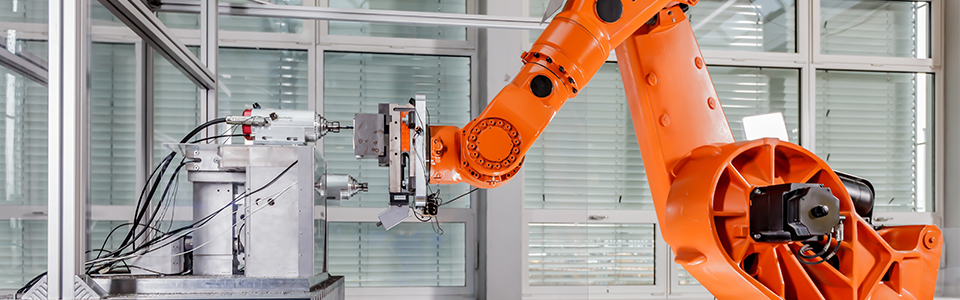

Robot cutting

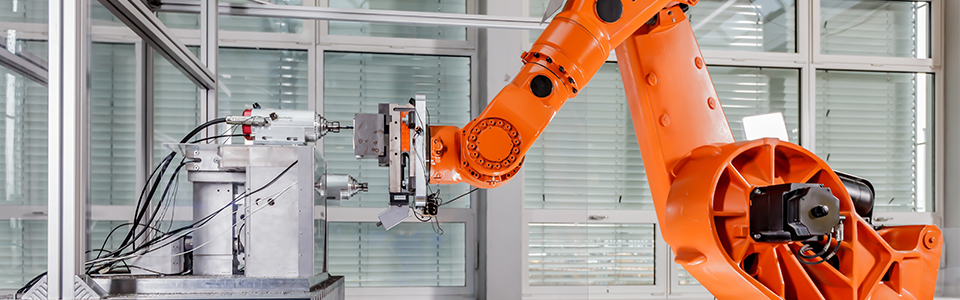

Industrial robots offer huge potential as guiding kinematics for cutting tasks. In comparison with machine tools, vertical articulated robots with up to six axes have a better ratio of workspace to construction space and lower investment costs. The high level of flexibility offered by the robot kinematics and the ability to integrate processes (e.g., machining, handling, assembly) enable complex tool geometries to be machined without the need for re-clamping and reduce the costs of the cutting process.

We are investigating robot-supported cutting processes as a way to drive the increasing use of industrial robots in the cutting industry. Our goal is to increase machining quality and accuracy by improving the vibration and displacement behavior of robots.

Case study — optimization of robot-supported cutting process

In the cutting process, dynamic interference in the form of different vibration phenomena can occur, particularly in the case of milling robots, which demonstrate a greater susceptibility to vibration due to their low structural, drive and bearing rigidity. An industrial project investigated the influence of different cutting and process parameters on the dynamic behavior of robots during milling operations with end mill cutters. The results provided a basis for recommending suitable cutting tools and parameters.

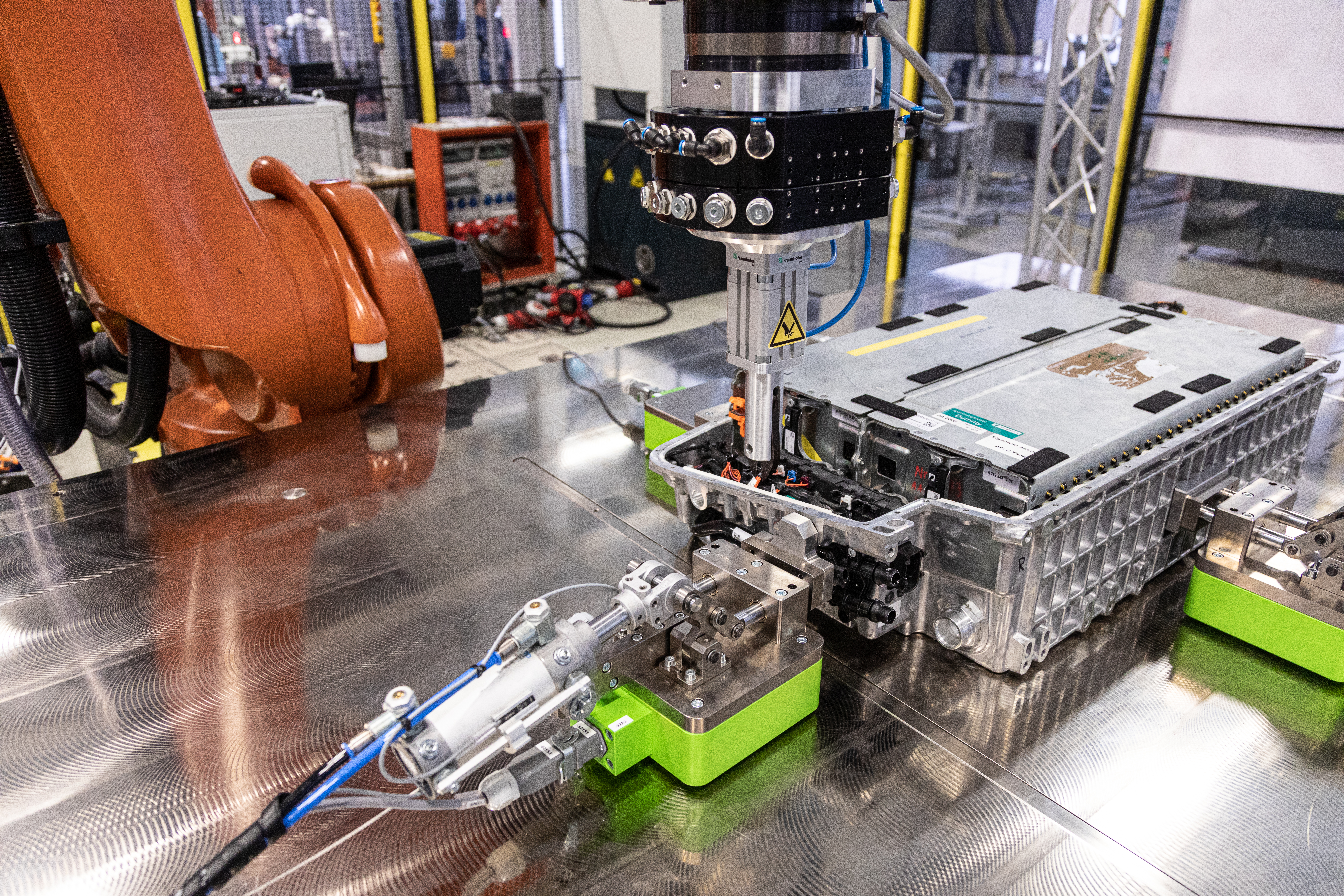

Case study — industrial disassembly of battery modules and electric motors

In the “DeMoBat” joint research project, a robot cell for automatic disassembly of battery modules from battery systems was constructed at Fraunhofer IPA and the feasibility of industrial disassembly was demonstrated under general economic and regulatory conditions. Severing and cutting methods for the robot-supported cutting of screw connections, plug connections and cables are important building blocks in the fully automated disassembly of battery systems. During the project, appropriate tools and processes were developed and validated.

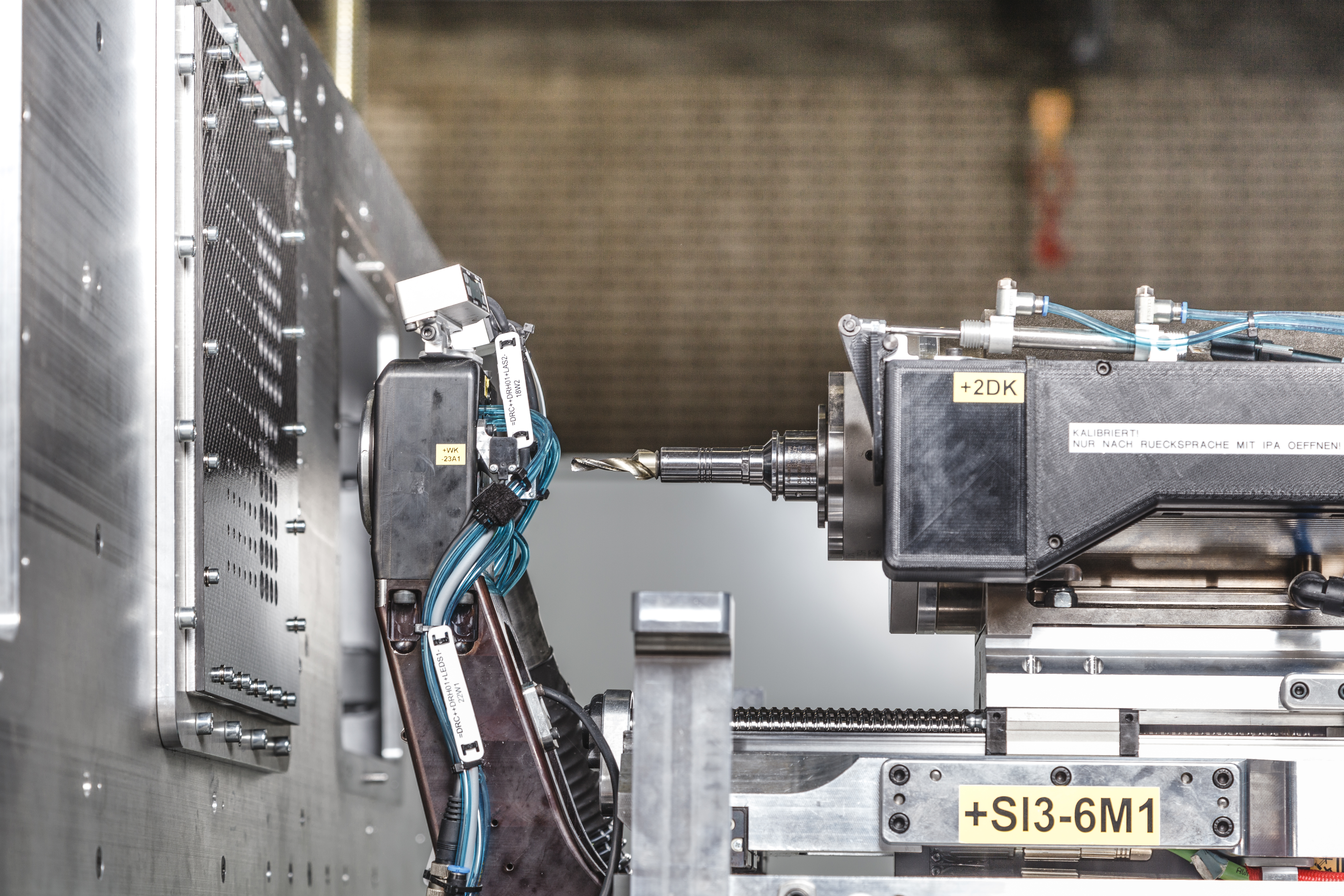

Case study — robot-based drilling and riveting

Drilling and riveting are key process steps in aviation and the automotive industry. In aviation in particular, the machining quality, countersink depth and orthogonality of the bore holes are subject to strict requirements. Conducted together with the company Lübbering, the “RDR” project involved developing a robot-based drilling and riveting end effector that meets the strict accuracy requirements of the aviation industry and processes a range of materials, including aluminum, titanium, carbon fiber composites and stacks.