Design and Selection of Joining Processes

Joining processes must always be precisely tailored to the respective application. That’s why we specialize in identifying the optimal joining method for your specific requirements. Thanks to our technology-neutral approach and broad expertise, we provide independent consulting based on a detailed requirements analysis.

We also support you in the development and further improvement of innovative joining technologies.

Case Study – Friction Stir Welding of Plastics

Traditional joining methods for fiber-reinforced plastics increasingly reach their limits, particularly due to the matrix-limited strength of the materials. We have developed a solution that enables fiber distribution across the weld seam, making full use of the fiber’s mechanical properties. This results in significantly higher joint strengths compared to conventional techniques.

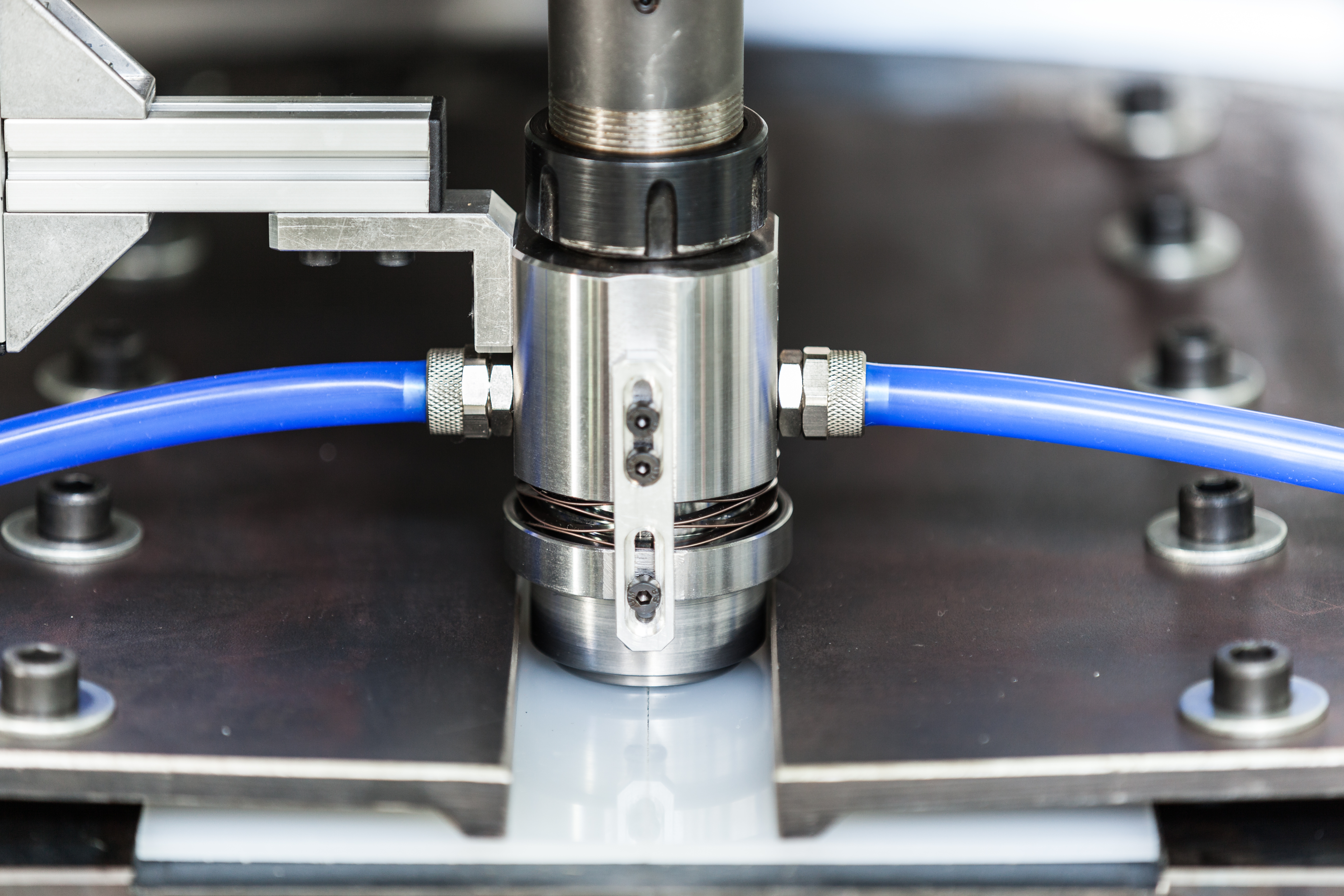

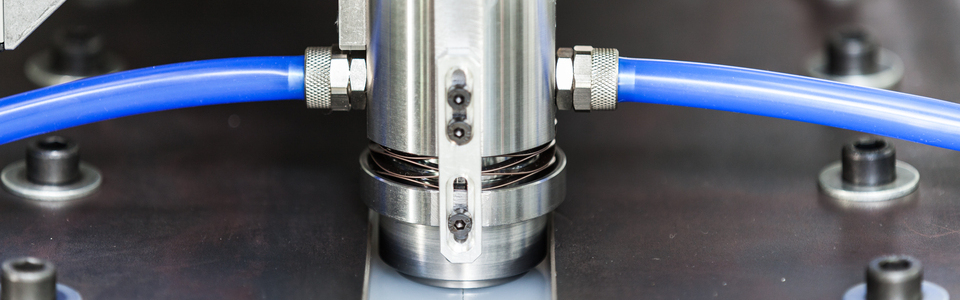

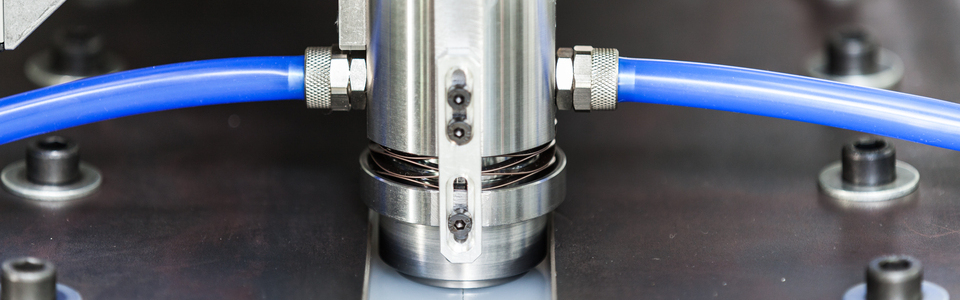

Case Study – Adhesive Bonding of Cutting Tools

Cutting tools are typically made from a tough tool body and a wear-resistant cutting edge. Conventional joining methods like brazing expose the cutting edge to high thermal loads, which can impair its performance. We have replaced brazing with adhesive bonding to reduce thermal stress, extend tool life, and enable the use of novel cutting materials.

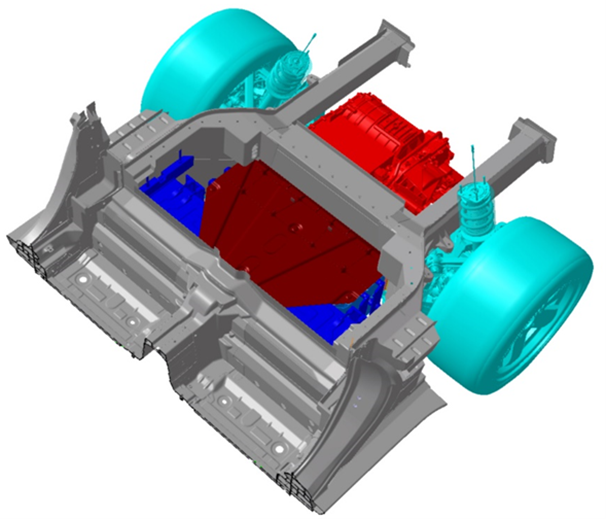

Case Study – Prototyping a Highly Integrated Rear Module

As part of the »HigHKo« research project, we developed a prototype of a highly integrated rear module for battery-electric vehicles. Our focus was on joining technologies for multi-material design. This included developing the JoinIT methodology for selecting suitable joining processes, a performance matrix to evaluate lightweight efficiency, and an adapted interface and risk matrix for hybrid assemblies.