Design and Simulation-Based Product Development in Lightweight Engineering

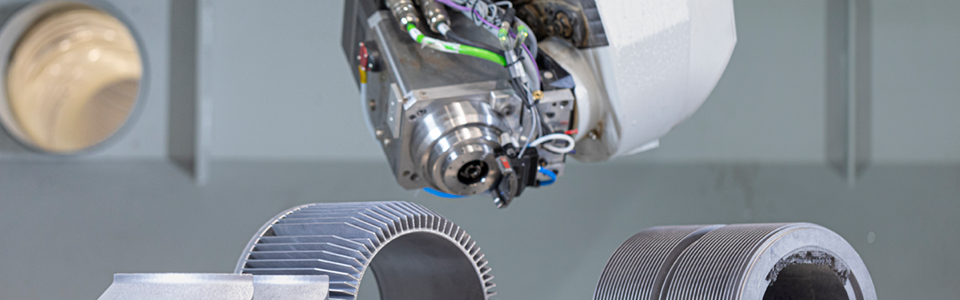

Modern design methodologies promote a systematic approach in which tailored methods are used to continuously improve concepts and prototypes. Combined with simulation tools such as the Finite Element Method (FEM) or Computational Fluid Dynamics (CFD), this enables the efficient development of application-specific products across various industries.

Significant added value is provided by the increasingly applied multi-material design. This approach allows the benefits of different materials to be leveraged, enabling targeted, component-specific control of properties such as strength, stiffness, and other characteristics – ultimately leading to significant weight reductions.

We support you in developing innovative, lightweight, and high-performance products that meet the demands of modern markets.

Case Study – Resource-Efficient Manufacturing of Weight-Optimized, Modular Lightweight Structures Using Typical Mechanical Engineering Components

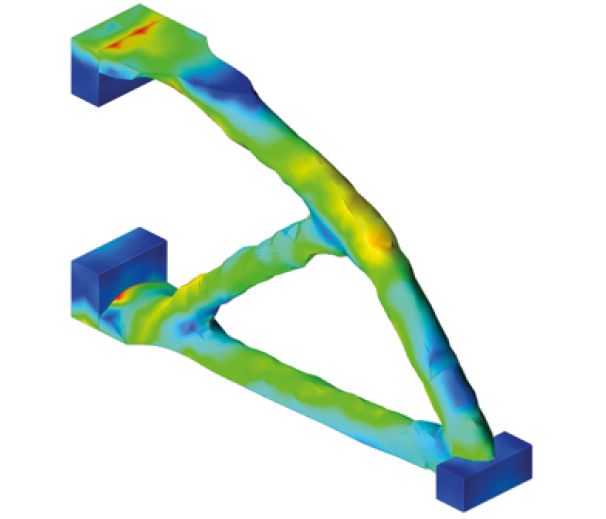

In the research project "RegemoLe", a method is being developed for the automated derivation of topology-optimized structures using differential construction techniques. This enables the use of standardized semi-finished products, which is particularly beneficial for cost-effective manufacturing of lightweight components in low to medium volumes. The newly developed design methodology and topology optimization approach are validated in practice using typical mechanical engineering components.

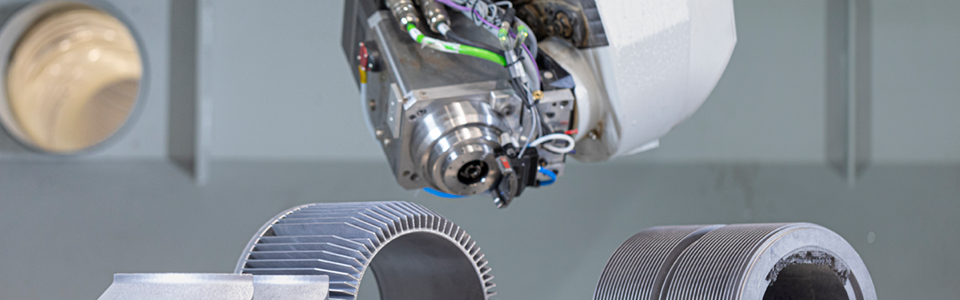

Case Study – Use of Novel Materials for Cutting Tools

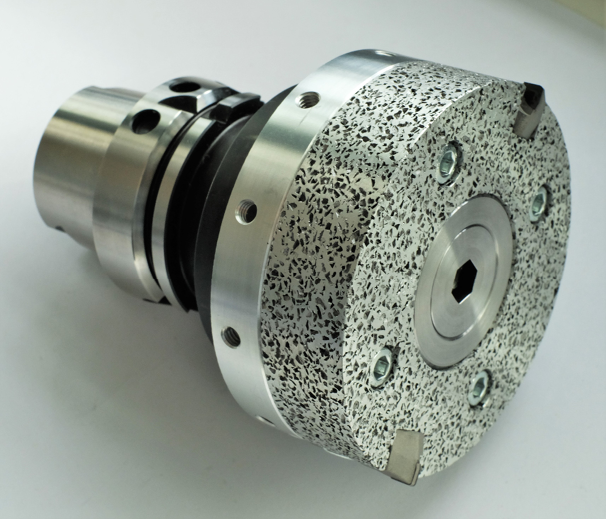

Open-pore cast aluminum offers a weight advantage of up to 60% compared to solid aluminum of the same alloy. This aluminum-hybrid material can be produced using a cost-effective permanent mold casting process with freely selectable pore sizes. We investigate its suitability for cutting tools used in the machining of metals, plastics, and wood. In addition to weight reduction, the material’s high damping properties improve tool performance. Further advantages include machinability with existing equipment, full recyclability, and customer acceptance of aluminum as a material.

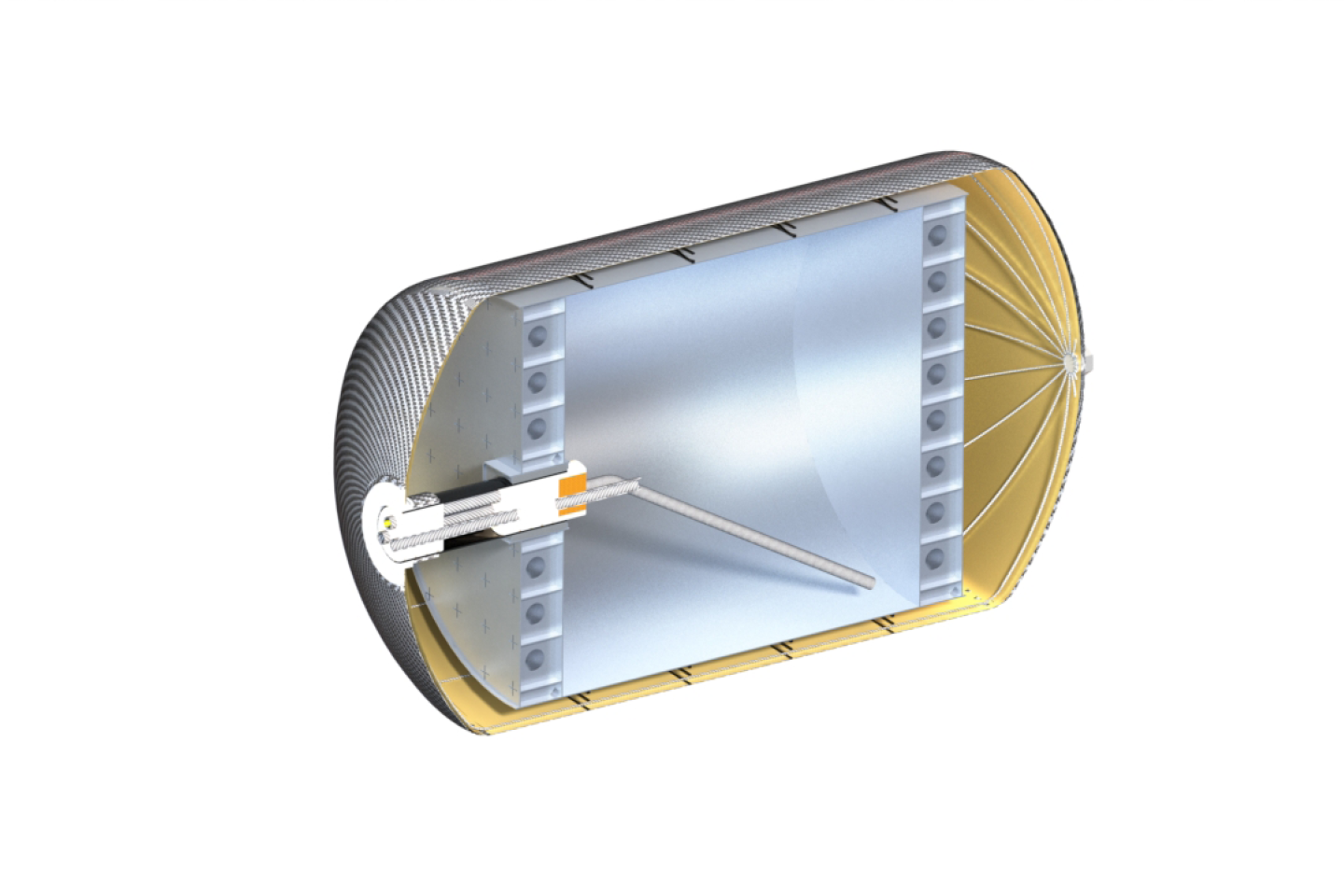

Case Study – Cost-Effective Lightweight Concept for a Liquid Hydrogen Tank Based on Hybrid Material Use

A tank concept was developed consisting of a replaceable inner aluminum tank made using sheet metal lightweight construction and a detachable CFRP outer tank. The inner tank, exposed to hydrogen and associated embrittlement, is designed to be replaceable and fully recyclable – enabled by the aluminum material. Leaks in the inner tank can be easily repaired, while the outer tank is reusable for numerous cycles. The differing thermal expansions of the two materials are compensated through design measures, combining the thermal insulation performance of a classic Dewar vessel with a double-walled tank structure capable of withstanding high mechanical loads, as required in aerospace applications.