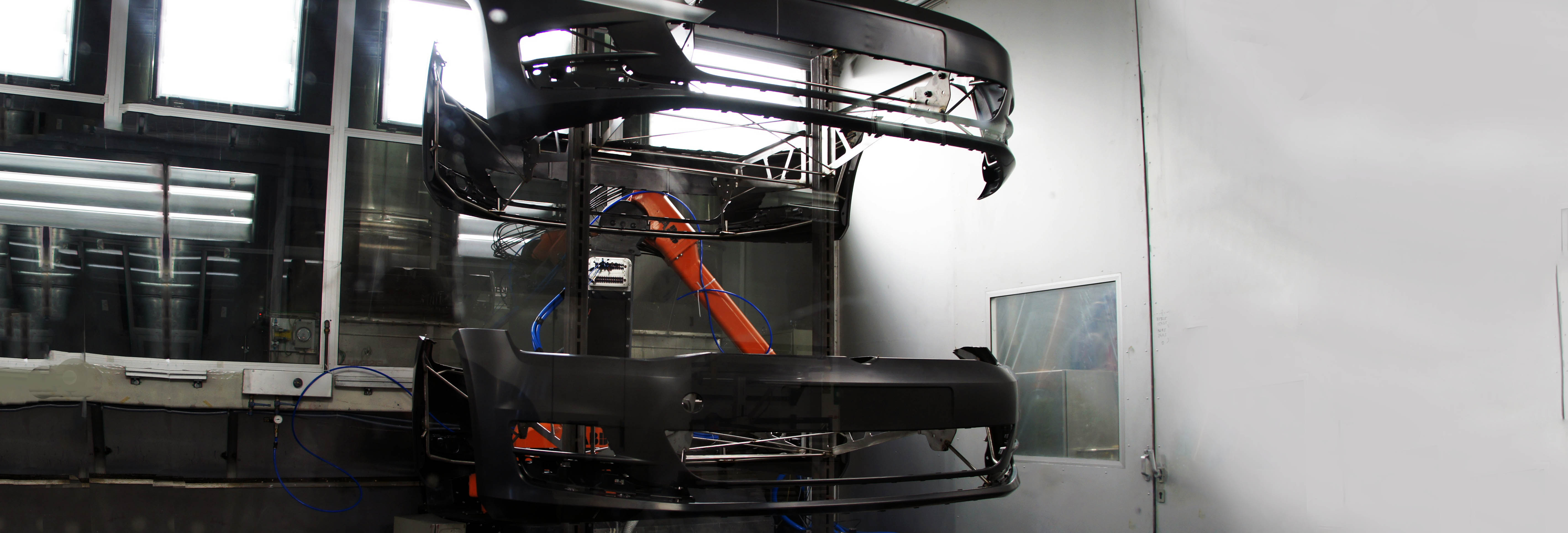

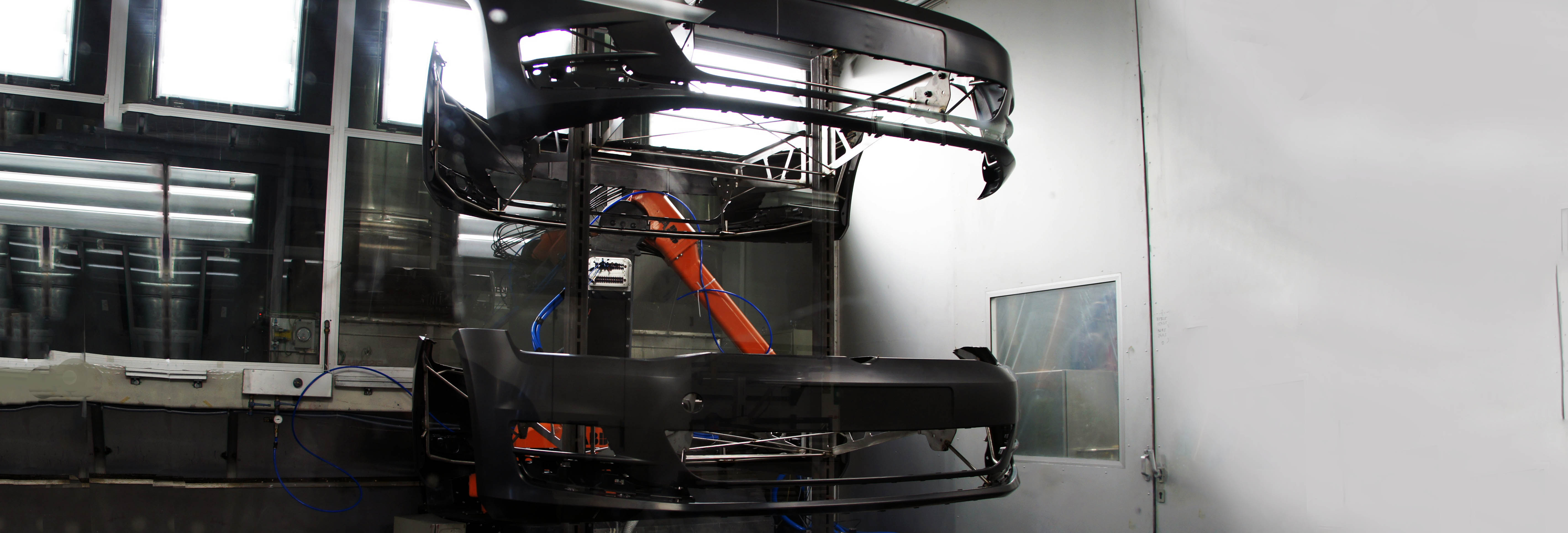

Feasibility studies for new materials and processes

Will the planned change in your coating process achieve what you hope?

If you want to implement a new coating process or coating system, or integrate a new material into your existing process, you may be asking yourself the following question: Will this change achieve the desired effect when it comes to quality, process stability, sustainability and efficiency? If the planned change is to be a success in practice, it must undergo comprehensive examination and testing to ensure that it is suitable for the industry.

Minimizing risk and increasing investment security

Feasibility studies play a key role in automation, digitalization and when setting up sustainable coating processes. They minimize the risk involved in technical developments and offer a solid basis for making investment decisions. Whether you are seeking to modify an existing coating system or develop an entirely new formulation, a feasibility study illuminates all aspects of the planned investment:

- Technological feasibility: Examining the implementation of new methods and materials

- Integration in existing production processes: How can the innovation be incorporated into your processes?

- Cost, efficiency and future analysis: Assessment of economic and long-term benefits

- Use of the latest testing and measurement technology: Safeguarding functionality with precision testing

- Examining suitability for industry: Tests in multiple pilot plants to simulate actual production conditions

Clear results for well-founded decisions

At the end of the process, you will receive a detailed report that evaluates the feasibility of your innovation in the context of your process chain. We will list the necessary measures, identify any potential restrictions and make specific recommendations so that you achieve success.

A professional feasibility study minimizes uncertainty so that you make well-founded decisions — for sustainable coating processes with future viability.