Automatic optical inspection (AOI) with machine learning

In short

This project extends existing optical quality control methods by machine learning techniques to reduce the pseudo error rate in automatic optical inspection (AOI). As a result, fewer manual follow-up checks are required, and workers are relieved of monotonous tasks.

In detail

Many manufacturers use AOI as a means of quality control in SMD production (Surface Mounted Devices). These systems use conventional image processing algorithms, which makes them high-maintenance and much less dependable where product variants are concerned. The automated inspection process therefore generates many pseudo errors, with the consequence that all hits need to be checked by hand.

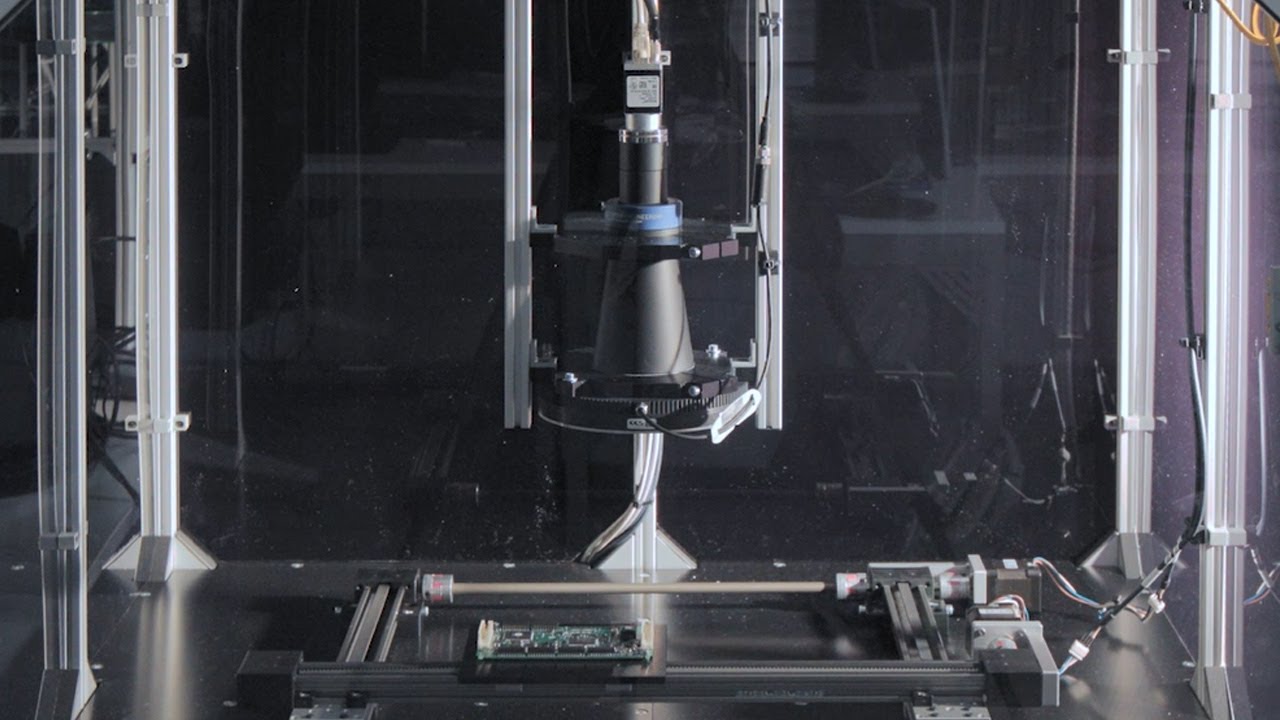

In the course of the project, a machine learning technique was developed that can distinguish between pseudo errors and real errors in an AOI. The technique is highly robust in the face of varying components. This greatly reduces the need for manual rechecks and eliminates these monotonous tasks. To better understand how the new technology works, the algorithm was implemented in a demonstrator that independently takes photos of defective components and thus imitates the AOI process (see video). The software is easily updated by simply adding new components to the training data set and carrying out a short re-training procedure.

Funding

Sponsored by the State of Baden-Württemberg, Ministry of Economics, Labor and Tourism

Insight into the project

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyVideo of the AI-based AOI. A machine learning technique detects devices mounted on a circuit board and marks those with defective components.