PaintVisco: Rheology and paint film flow

In Short

The “PaintVisco” research project explores the relationships between the properties of liquid paint and the waviness of the films formed by the paints after curing. The knowledge gained will be used to specifically improve the flow characteristics of paint films and to reduce development costs.

In Detail

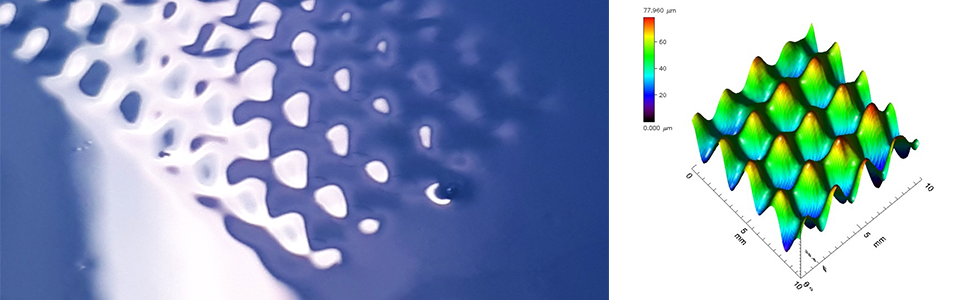

The term “paint film flow” describes the property of wet paints to automatically compensate for the unevenness occurring during their application. Up to now, optimizing the flow has been extremely labor, energy, time and cost-intensive because the properties and parameters of paints are modified step by step in extensive test series. The aim of the research project is therefore to simplify the task of optimizing the paint flow process. Producers of raw paint materials, technical consultants, paint manufacturers and paint processors are expected to benefit.

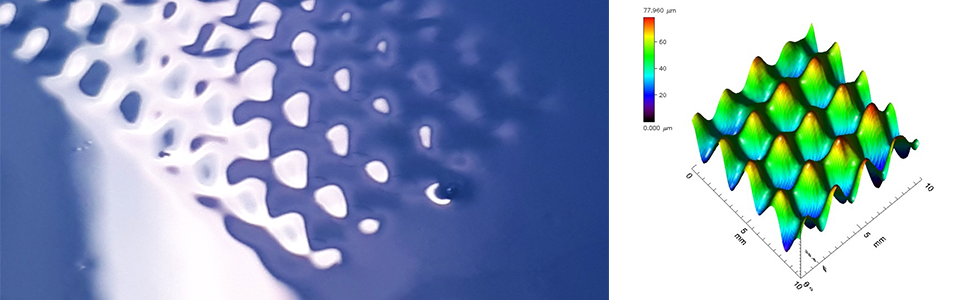

It is anticipated that the research project will deliver in-depth knowledge on the way relevant viscoelastic properties change over the course of the various process steps - atomization, flash-off and baking - and thus determine the final surface structure of the paint film. The necessary knowledge will be gained by measuring rheological properties, using them as input data in flow simulations and then comparing the simulated flow behavior with the measured paint flow. The rheological measurement procedure and paint flow models are adjusted until the simulated behavior matches the real flow.

For this purpose, the following aspects will be worked on:

- Existing flow models for idealized cases will be extended in order to simulate practical cases, such as the way paint flows over irregular surface structures during spray painting or down vertical surfaces.

- Various methods used to measure the waviness of paint films are being studied to evaluate their suitability for measuring the flow characteristics of liquid paints.

- The rheometer measuring cell and the rheological measuring procedure are adapted to simultaneously take thixotropy, evaporation and rises in temperature into account when measuring viscoelastic properties.

Further Information

Project time frame: 01.01.2020 – 06.30.2022

The project was submitted via the German Research Association for Pigments and Coatings (Forschungsgesellschaft für Pigmente und Lacke e. V.) to the German Federation of Industrial Research Associations (AiF Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e. V.) as joint industrial research (IGF). It is financially supported by the Federal Ministry for Economic Affairs and Energy (BMWi) under the funding code number 20994 N. Seventeen companies from the fields of raw paint material production, paint manufacturing, paint processing, technical consulting and measurement technology are involved in the project.