Implementation strategies for additive manufacturing processes

Additive processes create added value in industrial production

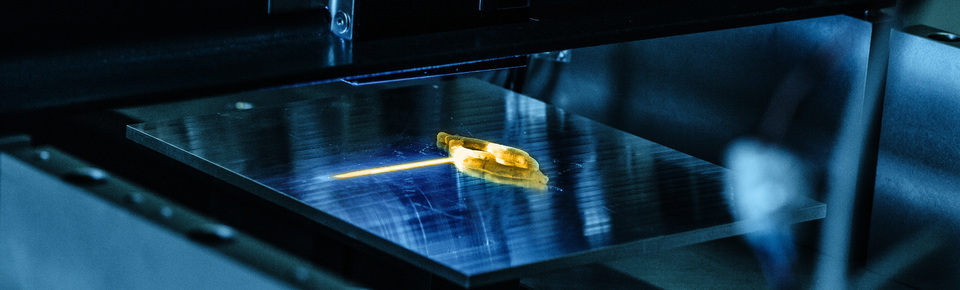

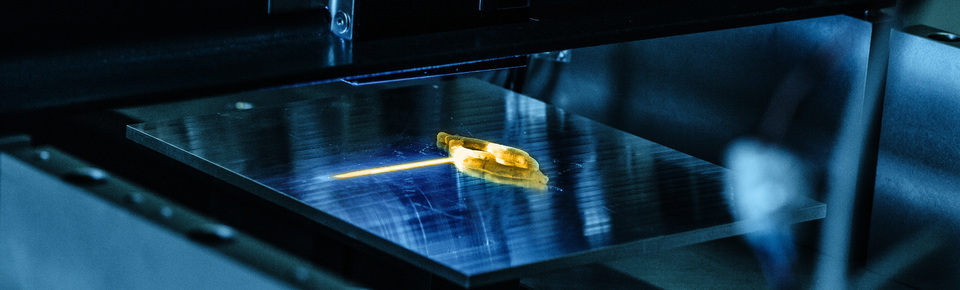

Additive processes - also known as 3D printing - have been used in the field of model and prototype construction for many decades. However, it is only in recent years that additive technologies have also become established in the field of production and are thus becoming the basis for existing and new business models. In the context of digitalization, additive manufacturing processes often open doors and, when used correctly, create unexpected added value.

Challenges and Benefits

Many companies expect additive manufacturing processes to provide major competitive advantages and facilitate the development of new business models. Other incentives include reintegrating production steps, integrating customers into the value creation process, and designing a flexible supply chain. To recognize and exploit this potential, Fraunhofer IPA brings together experts from various fields to offer companies a comprehensive range of services for introducing additive processes.

Approach

Whether you are just starting out or already have additive manufacturing processes in-house or are sourcing printed components from external service providers - we will support you with the right range of services:

- Would you like to determine if additive manufacturing is a good fit for your company? We can help you develop various application scenarios and show you how to evaluate them economically and develop new business models.

- Do you already know how you want to use additive processes in your company? We can help you select processes and equipment, as well as work with you to create a sound basis for strategic decisions on getting started with the technology.

- Would you like to use additive manufacturing processes in series production? We can help you further develop application scenarios, design end-to-end process chains, and develop new business models. With our expertise in additive processes, we can also assist with the application-specific development of these processes.