Agile business model transformation at EOS Electro Optical Systems

In short

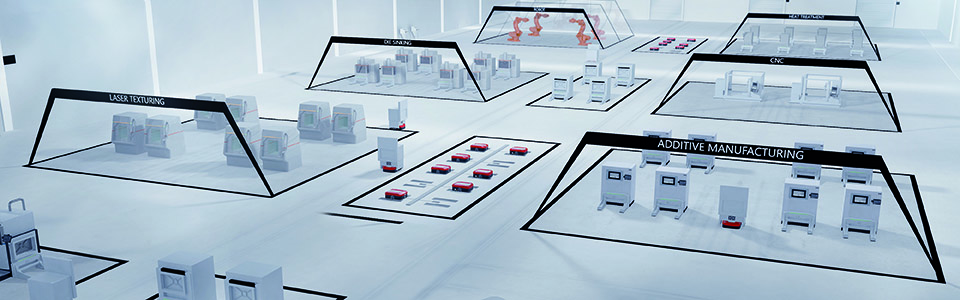

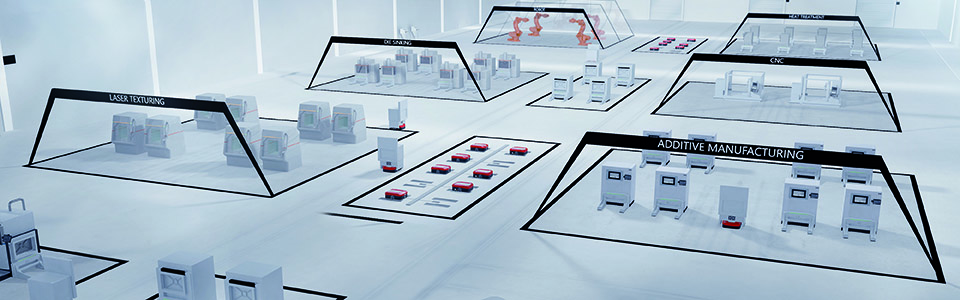

EOS GmbH offers its customers advanced systems for industrial 3D printing. It is also forging ahead with digitizing its own product development process. Together with Fraunhofer IPA, EOS has developed a new data-driven business model that can be used to generate even more added value for the customer.

In detail

Manufacturing with 3D printing is becoming inceasingly popular in the manufacturing industry. New technological requirements regarding maintenance, logistics and material procurement are often a challenge for users. EOS is already providing customers with assistance for this today. In the future, 3D printing cells, manufacturing systems, digital services and customers will be closely networked with each other. This is enabling EOS to further improve its customer services. EOS has developed a digital business model in cooperation with Fraunhofer IPA. The following aspects played a decisive role:

- Greater involvement of partner companies from the EOS ecosystem

- Target-oriented consolidation of existing EOS expertise

- Further development of core transaction business into performance-based revenue models

- Common understanding and willingness to change on the part of employees at all company levels

- Visionary attitude of decision-makers

Thanks to the new integrated solution for additive manufacturing and the data-driven business model based on it, EOS can now offer further added value opportunities to its customers and ensure sustainable growth.

In order to implement the new business model, adjustments needed to be made to the existing organizational structure. The hybrid organizational structure developed with Fraunhofer IPA makes it possible to continue to derive efficiency advantages from standardized organizational processes while driving innovation with the necessary agility and dynamism at the same time.

For the entire project, EOS and Fraunhofer IPA chose an iterative approach in small steps based on a Minimum Viable Product (MVP). This strategy allows EOS to pursue its vision with

- Phase 1: Analysis and expansion of the existing business model vision

- Phase 2: Definition and refinement of the core business model based on an MVP

- Phase 3: Analysis of current organizational development projects and preparation of a roadmap

- Phase 4: Development of an organizational structure for implementing and operating the MVP

- Phase 5: Methodical implementation support

Insights into the project

Together with Fraunhofer IPA, we have succeeded in laying the foundations for a data-driven business model that will establish EOS on the global market as a provider of highly-integrated additive manufacturing solutions.

Güngör Kara, Chief Digital Officer

EOS's new integrated additive manufacturing solution delivers many more customer advantages than just selling individual equipment.

Trevor Kirsten, Head of Digital Manufacturing