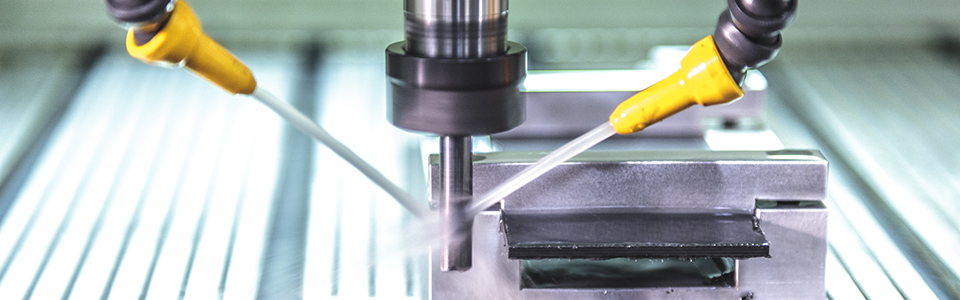

Coolant technologies

Coolants are essential to the process of machining many modern materials. They reduce frictional forces and discharge heat and chips from the machining zone. As such, they make a considerable contribution to reducing tool wear, improving machining quality and increasing process stability and productivity. It is essential that the coolant is adapted to the process and the material that is being machined. We will be happy to support you with our many years of experience and help you to optimize the design of your process.

Case study — coolants for composite materials

The process of machining composite materials involves a host of challenges. Due to the heterogeneous material properties, the cutting edges of the tool often undergo multiple load changes within a single cut. This often generates hard, abrasive particles of lubricant layers with strong adhesive properties, leading to early tool failure. The use of coolants can alleviate friction and prevent any adhesion. The use of wet machining improves machining quality, extends the tool service life and protects employees, as the coolant binds any harmful dusts.

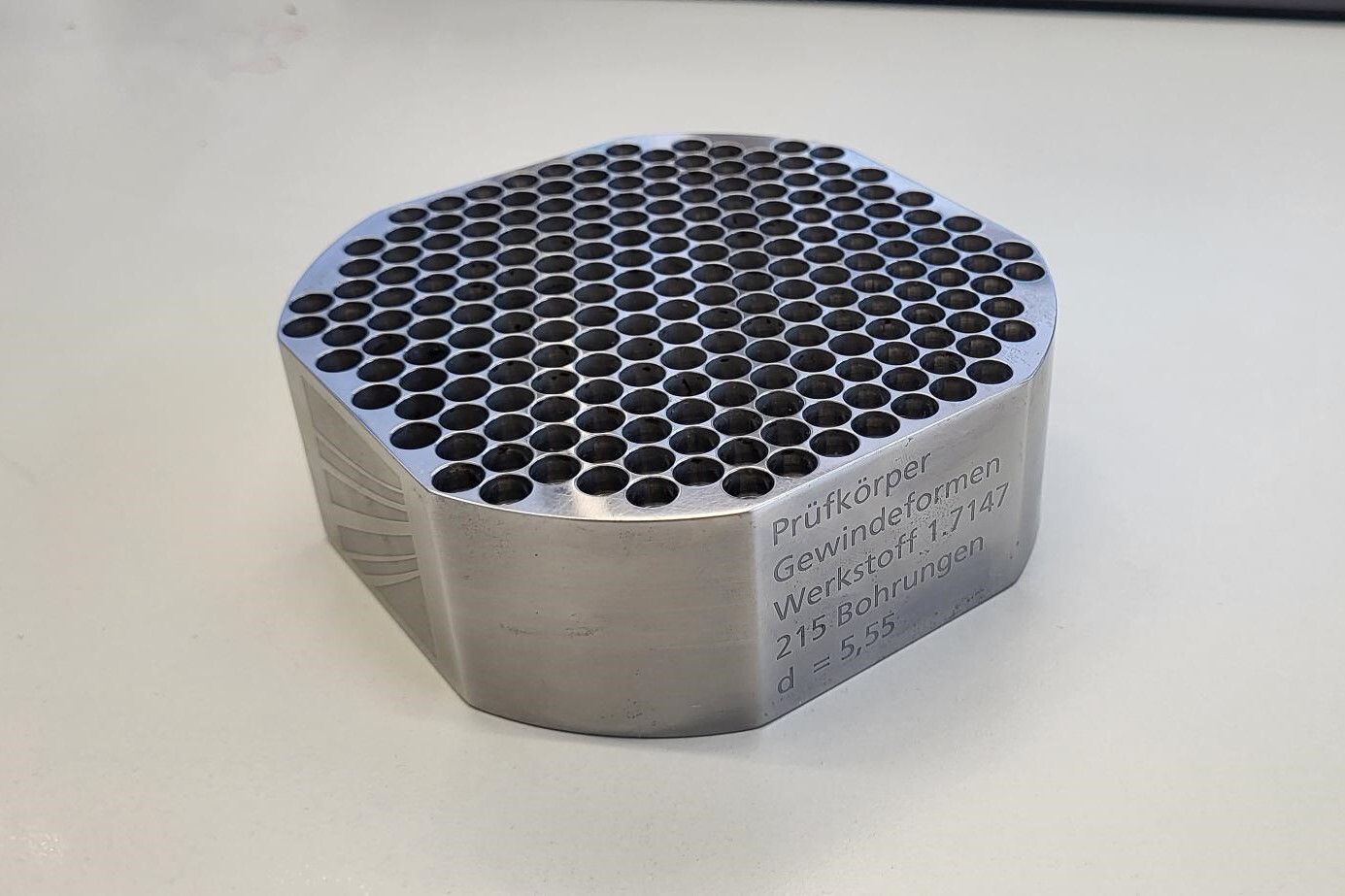

Case study — tapping torque test piece in special material

For suitability testing of various coolants in its production process, an industrial customer needed a test piece for the tapping torque test made from the material predominantly processed at its site. While the manufacturer of the test equipment only offers a small number of materials, we can manufacture test pieces in a wide range of materials (high-grade steel, wrought aluminum alloys, stainless steel, titanium, Inconel) and in almost any shape by drawing on our expertise in machining different materials. These meet all of the requirements defined in the standard, even exceeding them in places.

Case study — coolant compatibility testing of machine elements

Coolants come into contact with many different components during use. In addition to tools, workpieces, clamping equipment and the lining of the interior, there are various scrapers, seals and pipelines that come into contact with media. Aging tests and subsequent examinations can be used to determine whether contact poses no risk to the components or whether the machine may be damaged in the long term.