AI-supported grouping, nesting and scheduling

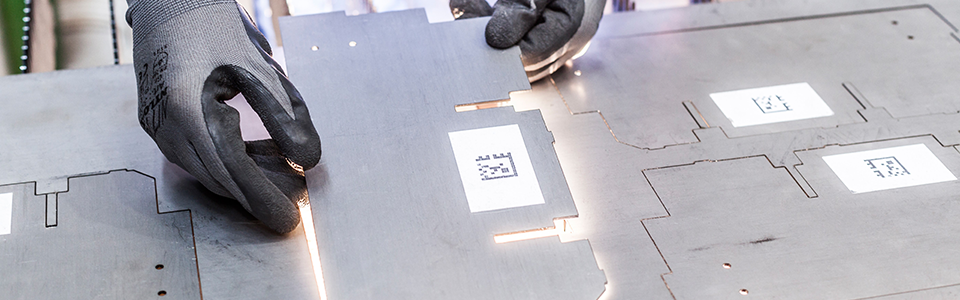

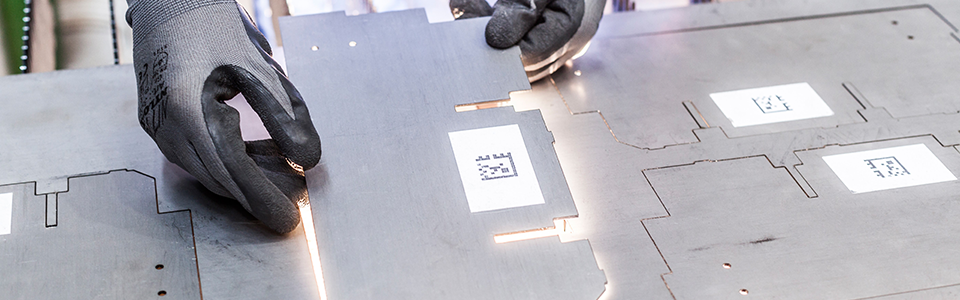

When laser-cutting sheet metal, orders and sheets are brought together into groups that require nesting. The nesting process ensures that the components are distributed optimally across sheets for laser-cutting. In the scheduling process, the nested sheet metal is distributed over the available machines to ensure the production process is organized and runs on time. This is one of many examples in which we can help you to automate and optimize grouping, nesting and scheduling tasks.

Value proposition

Our solution comprises the development of custom algorithms and software modules that are based on a hierarchical approach and include both mathematical optimization and reinforcement learning. By integrating these methods, we aim to achieve maximum efficiency and material utilization in complex production processes.

Investment and scope of services

For an investment starting from 50,000 euros, you will receive the following services:

- Analysis of production processes and challenges for selected products

- Development of custom AI-supported algorithms and software modules for automated processing of grouping, nesting and scheduling tasks

- Implementation of the developed solutions in the customer’s production environment