Digital twins in industry – efficiency, transparency, and quality in real time

Your supplier sends you an updated parts list, but the data does not match your system. Files are sent back and forth for weeks, changes are coordinated by phone, and errors are only discovered during production. This costs time, money, and nerves. With a digital twin, everyone involved, from the supplier to the final assembly, has access to the same, up-to-date data. Changes are visible in real time, systems communicate seamlessly with each other, and misunderstandings are a thing of the past.

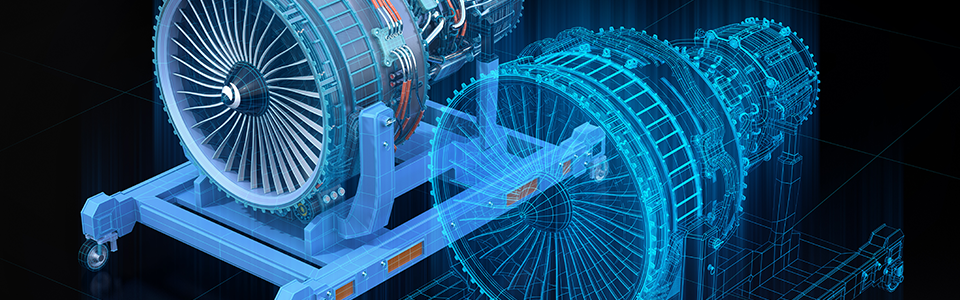

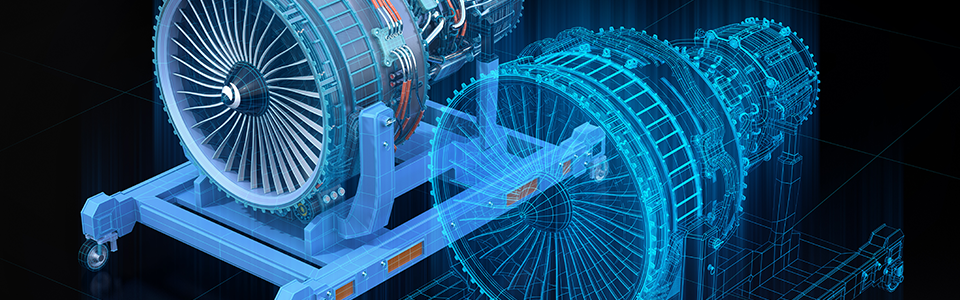

What are digital twins?

Digital twins are virtual representations of real machines, systems, or products. They provide real-time information on status, usage, and performance, thereby supporting transparent decisions and efficient processes throughout the entire product and production life cycle.

Various approaches and technologies are available for implementing digital twins, such as the Asset Administration Shell (AAS) (IEC, 2023). What they all have in common is that they provide all relevant data in a structured and machine-readable form, thus enabling smooth interaction between the digital twin and connected systems.

The digital twin is not a visualization or a standalone technology, but rather a concept that unleashes its potential in combination with other technologies such as the Internet of Things, cloud or edge computing, and artificial intelligence (AI).

This enables a wide range of applications, from predictive maintenance and process optimization to simulation and virtual commissioning to improved traceability, quality assurance, and error detection.

What types of digital twins are there?

There are different types of digital twins, which differ according to their area of application:

- Product twins

- Process twins

- Plant twins

- Quality twins

What advantages do digital twins offer for industry?

Real-time transparency and compliance: Compliance with supply chain legislation with product and supply chain information for a complete and auditable database (Wagner et al. 2024).

Sustainable efficiency gains: Increase productivity and reduce costs with AI support (Meyer et al. 2025).

Faster process and quality optimization, less downtime: Reduction of downtime with AI quality control for early fault detection (Shi et al. 2024).

Accelerate development and simulation:

- Up to −88.5% orientation time when restocking shelves; −71.5% total search time for new employees (Graf et al., 2024).

- 14x faster reactions and decisions in the development of a robot work cell through digital twins with RAG system (Shi et al. 2025).

Our digital twin solutions in detail

Development and implementation of digital twins

Participating companies benefit from:

- Comprehensive analysis of existing infrastructure and a customized implementation approach

- Expert support in setting up digital twins and integrating them into existing systems

- Development of standard and custom models to optimize digital twin technology

Which companies benefit most from digital twins?

This project is ideal for companies that have already taken their first steps toward digital twins and are aiming for full implementation. It is aimed at organizations that need deeper customization of their systems and are willing to invest in comprehensive modeling work.

What does it cost to develop a digital twin in industry?

The project is calculated individually based on the scope and complexity of the requirements. The cost structure is as follows:

- Base price for identifying the use case and developing a model: starting at €40,000.

- Additional $4,000 per additional standard model or $9,000 per special model, depending on the complexity of the use cases.

Use digital twins for your company

Interested in how a digital twin can optimize your processes? Feel free to contact us for a no-obligation consultation or an initial analysis of your production data.

Sources

Graf, F., Bazlen, F., Degel, S., & Lindermayr, J. (2024). Intelligent pointer unit to speed up the shelf replenishment process in retail stores. Dynamics in Logistics. https://doi.org/10.1007/978-3-031-56826-8_35

International Electrotechnical Commission. (2023). IEC 63278-1:2023—Asset Administration Shell for industrial applications: Part 1, Asset Administration Shell structure. https://webstore.iec.ch/en/publication/65628 (Retrieved October 20, 2025)

Meyer, O., Albers, L. C., Schwab, J., Schuller, A., Leippert, M., Munz, B., Schel, D., & Eigenbrod, H. (2025). Quality improvement through digitalization: Use of AI methods and digital twins in the production of satellite components. ZWF – Journal for Economic Factory Operation. https://doi.org/10.1515/zwf-2024-0120

Schade, R., Speckmann, F.-W., & Birke, K. P. (2025). Ranking of novel criteria for prioritizing production-relevant quality-critical product parameters of electrolysers and fuel cells. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2025.03.251

Shi, D., Liedl, P., & Bauernhansl, T. (2024). Interoperable information modeling leveraging asset administration shell and large language model for quality control toward zero defect manufacturing. Journal of Manufacturing Systems, 77. https://doi.org/10.1016/j.jmsy.2024.10.011

Shi, D., Li, J., Meyer, O., & Bauernhansl, T. (2025). Enhancing retrieval-augmented generation for interoperable industrial knowledge representation and inference toward cognitive digital twins. Computers in Industry, 171, 104330. https://doi.org/10.1016/j.compind.2025.104330

Wagner, E., Kegler, S., Gallina, V., Aigner, T. M., & Koller, J. (2024). How industrial data meets information requirements of the digital product passport: The case of remanufacturing data. Electronics Goes Green 2024+. https://doi.org/10.23919/EGG62010.2024.10631243