Effects analysis – identifying relationships in production

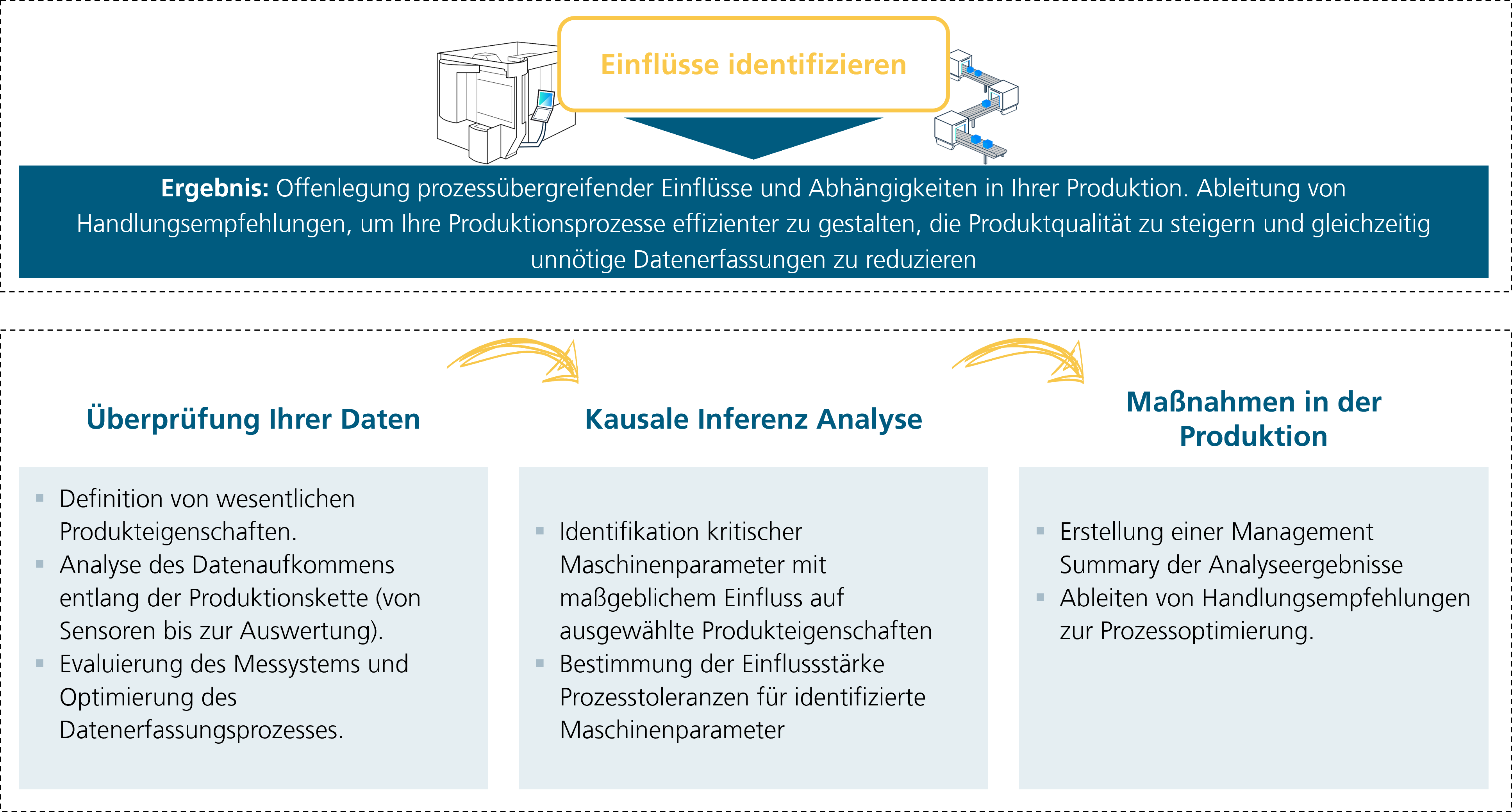

Cause-and-effect relationships are the key to understanding mechanisms in production. The difference between causality and correlation is crucial in this regard. We offer a detailed effects analysis aimed at identifying the effects and relationships across production processes. By using the latest methods of causal inference, we can help you to identify the precise relationships between machine parameters and production properties so that you can optimize your production processes.

Value proposition

Use our expertise to capture your production data efficiently, reduce unnecessary data overloads and identify the relevant relationships between machine parameters and product quality. By applying causal inference, we can offer detailed findings to improve your production processes and increase the quality of your products.

Investment and scope of services

With a proof of concept, we can offer the following services, starting from 25,200 euros:

- Analysis of the data gathered throughout the production chain (from sensors to evaluation).

- Evaluation of existing measuring systems and optimization of the data capture process.

- Identification of critical machine parameters that influence key product characteristics in order to determine the causal relationships and effects.

- Development of recommended actions to optimize processes.

Procedure and expected results