Center for Particle Technology

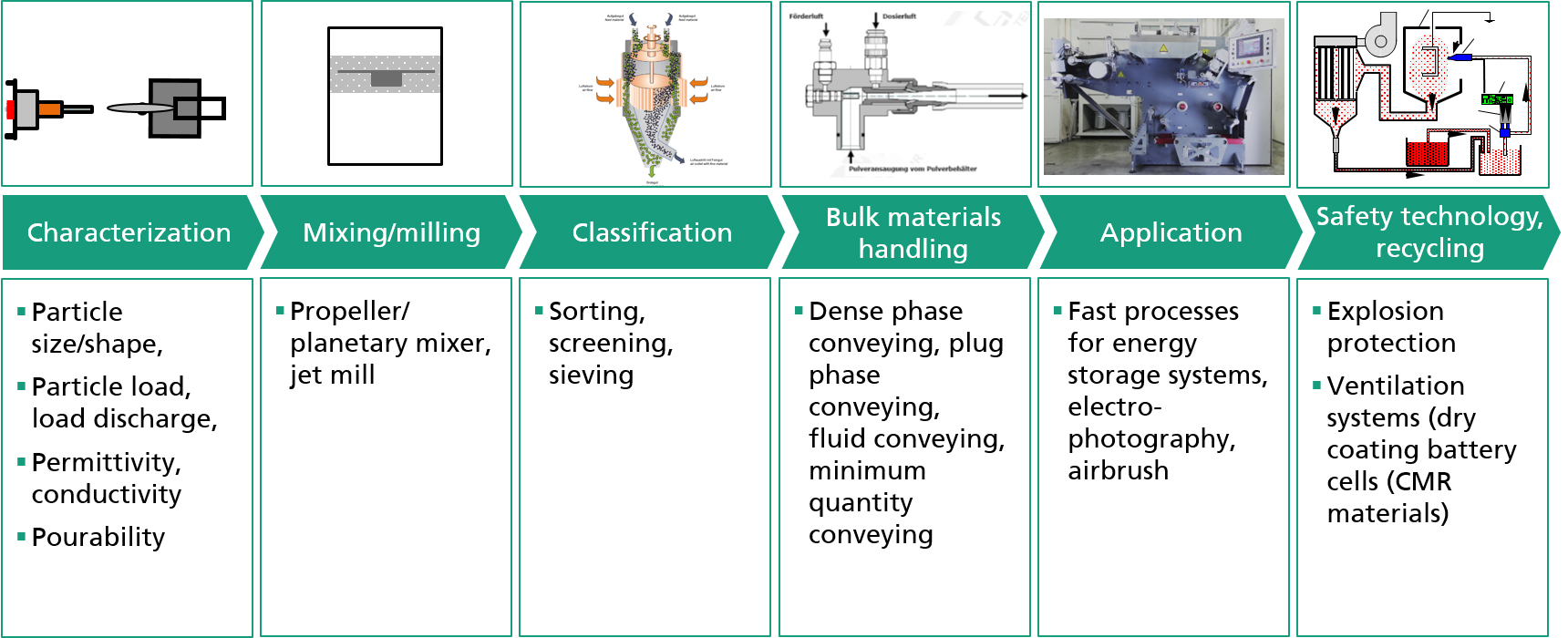

Fraunhofer IPA has decades of experience in the field of surface technology and bundles this expertise in its Center for Particle Technology, where it also cooperates with the Department of Ultraclean Technology and Micromanufacturing and the Center for Additive Manufacturing. Taking a comprehensive and interdisciplinary approach, the center covers the entire process chain of particle technology, from the development of basic scientific principles right through to industrial applications.

Manufacturers, users and Fraunhofer IPA researchers meet up in the application center to discuss issues on an interdisciplinary basis. With IPA acting as a supporting research institution, current techniques can be improved and new techniques tested under realistic production conditions in existing and future laboratories and pilot plant facilities. Research issues address topics related to particle manufacture and processing with the corresponding work safety measures, as well as energy and resource efficiency and environmental protection.

The focus is on application-oriented consulting, process comparisons and fundamental research projects on

- basic processes for powders and bulk materials, equipment and process components,

- packaging and filling,

- nanoparticle technology,

- testing, control, automation, digitization, topics related to Industrie 4.0,

- safety and environmental technology, explosion protection and quality control, assurance and management.

Applying powders in a roll-to-roll process

When it comes to manufacturing electrodes for electrochemical energy storage devices, coating current collectors is a key process. Materials used so far require energy-intensive drying processes and release solvents that are hazardous to people’s health and to the environment. The powder coating technology based on the TransApp® process not only eliminates this potential hazard but also offers further advantages.

Numerous customer-specific tests carried out in the pilot plant at Fraunhofer IPA with the Austrian partner company TransApp-GmbH prove the excellent coating results of this application technique which does not require the use of a powder gun: the processes of pre-treatment, powder application, baking and cooling can be significantly shortened, saving both on energy and costs.

With this in mind, a method of applying the dry-blend functional material by electrostatic deposition to the current collector foil without the use of a gun was developed at IPA as part of the Elibama (European Li-Ion Battery Advanced Manufacturing) research project.

To dry the material, Fraunhofer IPA uses an infrared temperature treatment technology with short- and medium-wave heaters operated by gas and electricity. Application-specific adaptations of coil coating processes are often developed with the partner institute CRM in Liège, Belgium. Using a modified technique, electrodes for energy storage cells are manufactured on an experimental scale in Stuttgart using a roll-to-roll powder coating process.

Applications

Cudazzo, M.; Hubrich, C. (2019): Flüssigkeitsgefüllte Mikrokapseln für Pulverlack

In: In: besser lackieren 21 (5), S.6

Cudazzo, M.; Pulli, K. (2018): Pistolenlose Pulverbeschichtung

In: besser lackieren 20 (18), S.6

Cudazzo, M.; Joachimi, C. (2019) Wärmeleitung in Pulverlack

In: besser lackieren 21 (19), S.6

Landwehr, I. (2018): Elektrodenfertigung mit Pulverbeschichtung

In: besser lackieren 20 (11), S.6

Schälicke, G. et al (2020): Solvent-Free Manufacturing of Electrodes for Lithium-Ion Batteries via Electrostatic Coating

In: Energy Technology 8 (2), Art.No. 1900309, 8 S

Poster »Funktionsschichten für elektrochemische Speicher und Wandler« [ PDF 0,44 MB ]