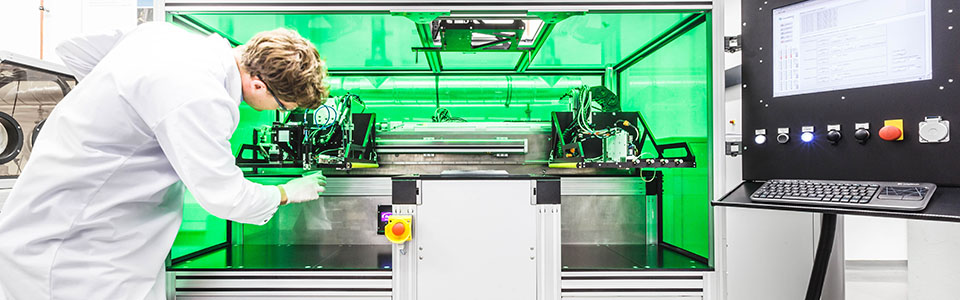

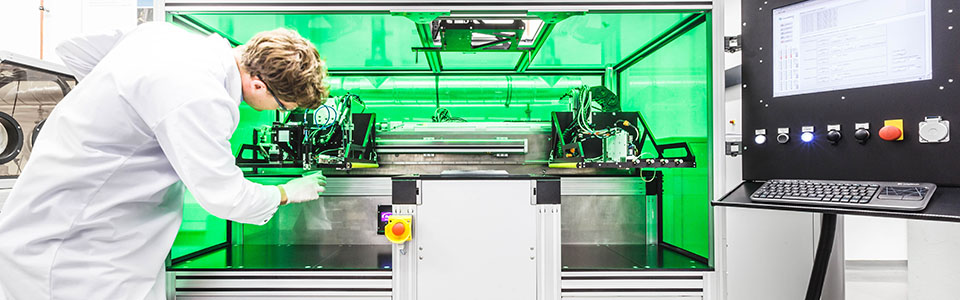

Developing Additive Manufacturing Processes

At Fraunhofer IPA, additive manufacturing technologies are further developed to process polymer-based materials. Applications are as diverse as the material properties which can be achieved. From transparent plastics, through fiber-reinforced materials, right up to ceramic slurries, a huge variety of materials are used. All standard additive manufacturing processes can be implemented on test benches in the laboratories to optimize and further develop processes as freely as possible. Different additive technologies can also be combined. Specific demands made by potential users from a wide range of industries are the drive behind all developments. Thanks to the equipment and expertise available, Fraunhofer IPA can offer a broad range of services, from technology consulting through feasibility studies right up to developing new additive processes and implementing them on test benches, as well as in process modules and manufacturing machinery.