Digital Printing Technologies

Functional digital printing

Inkjet printing and electrophotography (better known as laser printing) are the most popular digital printing technologies. They are generally used to decorate paper and other paper-like materials. However, apart from these purposes, they can also be implemented in interesting applications in digital functional printing.

Piezo inkjet

For many years now, inkjet technology has been indispensable in the printing industry – from home office printers right up to professional poster printers. However, this technology opens up many more possibilities than just these. Apart from decorative applications on paper, it can also be implemented as a lucrative industrial manufacturing process. The flexible technology is still relatively uncommon in this field despite the fact that it can be used in a wide range of applications. For example, it could replace screen printing processes or be used to create individual conductive layers. Biomedical applications are also conceivable. Or we could simply exploit its advantage of being able to apply sharp-edged selective coatings in a contact-free process practically without production waste.

A wide variety of materials can be processed: UV-curing substances and solvent-based materials are suitable, as well as water-based paints. However, as opposed to other methods, only low-viscosity materials can be applied and the proportion of solids they contain cannot be increased at will.

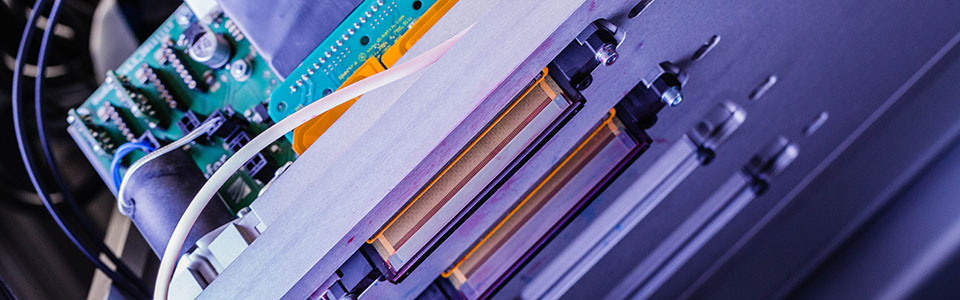

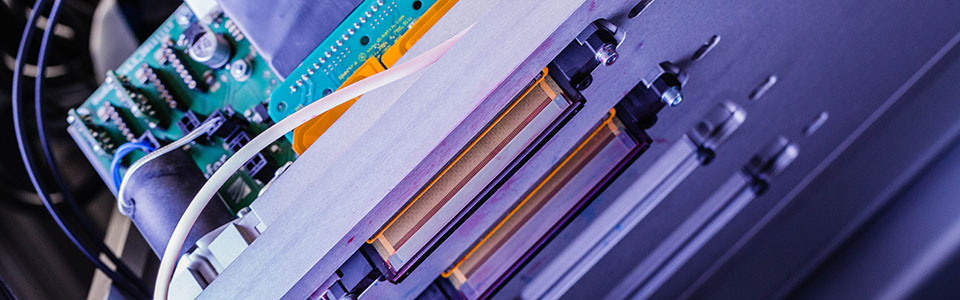

Electrophotography

Electrophotographic printing as a digital printing process is often overshadowed by the better-known inkjet technology. However, from a technical point of view, this is completely unjustified. Electrophotography is a robust and efficient process for applying substances in powder form. Just as with inkjet technology, this technique originated in the printing industry and is implemented comparatively rarely in industrial applications. However, there are two main differences. On the one hand, the substances processed are generally in powder form. On the other hand, this is a contacting technology. Although it is used for different applications compared to inkjet printing, this does not make it any less attractive. For example, this efficient printing method is implemented to manufacture biochips (peptide arrays). The technology and materials required were developed in a cooperation between Fraunhofer IPA and the German Cancer Research Center DKFZ. This example is typical of the type of expertise offered by Fraunhofer IPA. The working group is characterized by its ability to apply prints onto a wide range of substrates, particularly inelastic materials. It also has the necessary know-how to develop its own printing mechanisms. Advice on material selection and feasibility. Besides requiring a high degree of flexibility, these manufacturing technologies also place certain demands on material parameters. This often makes it impossible to use materials known from other application technologies in digital printing processes in an identical way. We help our customers to implement and integrate digital printing processes, from giving advice on feasibility studies and processability tests, right through to further developing existing materials or even developing completely new ones as required. We see ourselves as integrators and draw on an extensive network of material manufacturers and developers.

Process and plant development

To benefit from the advantages of digital printing technologies, it is often impossible to implement existing processes in an identical way. New concepts are required for the materials used, as well as for upstream and downstream process steps. Additionally, most of the printing heads and systems available on the market are designed for decorative applications on paper-like substrates, making it necessary either to adapt them accordingly or develop new ones. We have been assisting our partners and customers in this field for many years. Our services range from feasibility studies, through integrated process development, right up to constructing appropriate printing systems, peripheral equipment and complete test benches. In cooperation with special equipment manufacturers, we can also develop systems suitable for production.