Biomimetics in Medical Engineering

Tabbed contents

Expertise

The group "Biomimetics in Medical Engineering" comprises engineers and scientists from the fields of technical biology, electrotechnology, mechanical engineering and mechatronics.

Biomimetics uses animals, plants and humans as models to develop products, surgical instruments and replacement body parts, such as implants and prostheses. Models of animals are carefully studied and their efficient principles transferred to innovative concepts, which are then tested. According to current estimates, there are around 1.25 million living and 130,000 million extinct species of animals. Hands, feet and mouth parts are effectors used to cut, sting, suck or grip. Surgical instruments must also be capable of these functions.

We place great importance on the design of biomimetically-inspired surgical instruments, prostheses and orthoses, ensuring that they have an aesthetic and biomimetic appearance. This is where the phrase “form follows function” comes into play. This means that the function of shape and, where applicable, color, must be justified and make sense, particularly from the aspects of ergonomics, weight reduction and usability.

A few examples of our biomimetic developments:

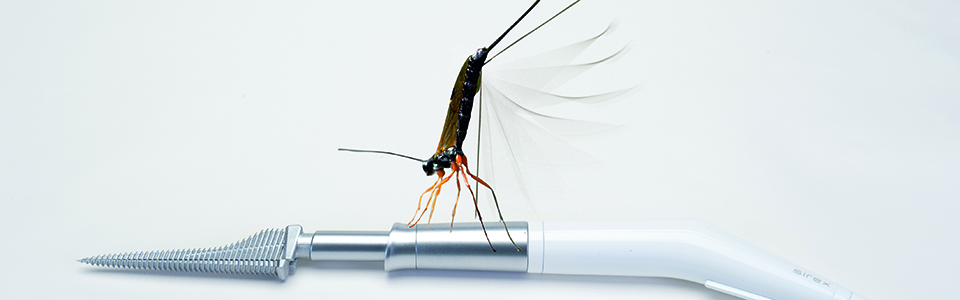

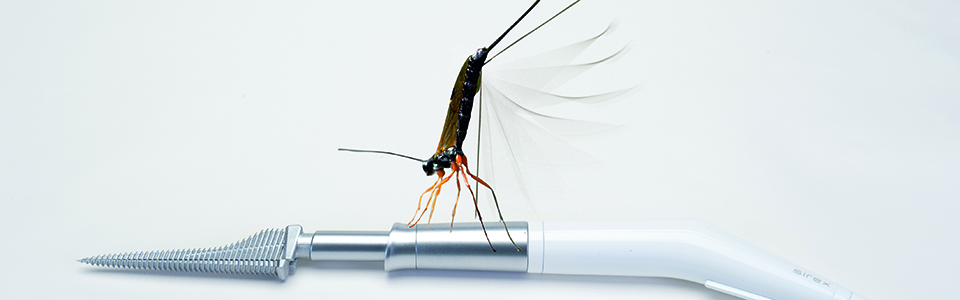

- The Sirex drill, modeled on the wood wasp

In medicine, such as with hip and dental implants, or anywhere else where dowels need to sit securely, angular edges guarantee a torsion-resistant fit. Inspired by the technique used by wood wasps with their drill lances that slide next to one another - the pendulum stroke technique - the biomimetic Sirex drill can shape any bore geometry, either straight or curved. For example, femurs can be hollowed out so accurately that the shaft of an artificial hip joint is inserted with a perfect fit. - Lightweight roadster modeled on the skull of an ichthyosaur

The skull of the simosaurus – an ichthyosaur that lived on Earth for 165 million years - is used as a model for an extremely robust roadster. The great advantage of the two-seater is its safety: in a head-on crash, energy is absorbed by the entire structure, thus protecting the passengers inside. The complete vehicle has an aluminum hull 1mm thick and weighs just 500kg. - New treatment for patients with chronic venous insufficiency (CVI), modeled on the three-cusp heart valve

As a new treatment for chronic venous insufficiency, a technology has been developed to reproduce venous valves in leg veins using a polymer. The valves display optimum flow characteristics without a tendency to develop thromboses. The design is based on the three-cusp heart valve, as well as on the surface structure of blood vessels and the formation of gradient materials – a universal principle of nature applied to reduce shear stress. - Bone punch modeled on the swallowing mechanism of a snake

We developed the bone punch based on a snake’s swallowing mechanism. Designed with teeth and a reservoir, the bone punch can be used to cut, transport and store pieces of tissue. The cutting mechanism is similar to the way carnivores use their incisors. This reduces the cutting forces required by up to 50 per cent.