Heating and Cooling

The progress of the energy turnaround poses new challenges for the manufacturing industry and energy supply companies. The balance between energy consumption and generation must be ensured at all times. Electricity prices and uncertainty about future energy price developments are rising. In addition, the aspect of climate neutrality is becoming increasingly important.

Particular attention must be paid to heating and cooling, which is responsible for 75 % of the total energy consumption in the German industry. The aim is not only to reduce energy costs in the short term. Sustainable, economical and future-proof thermal energy supply concepts and technologies are called for.

Selecting the right energy source, the appropriate technologies, and coupling and integrating energy storage systems is no easy matter. It all depends on the thermal energy levels required, where the energy will be used, the production processes involved, and, of course, the company's objectives. We help you find the ideal solution for your needs, independent of the manufacturer and technology.

Our services and expertise:

Together with you, Fraunhofer IPA develops problem-driven strategies and solution approaches to ensure a sustainable, efficient and robust energy supply:

- Development of climate-neutral, thermal energy supply concepts

- Design of concepts for hybrid production machines

- Development of integrated energy systems

- Identification and assessment of energy flexibility potentials

- Development of hydrogen use paths

- Evaluation of thermal energy storage systems

- Modeling and numerical simulation of thermal systems

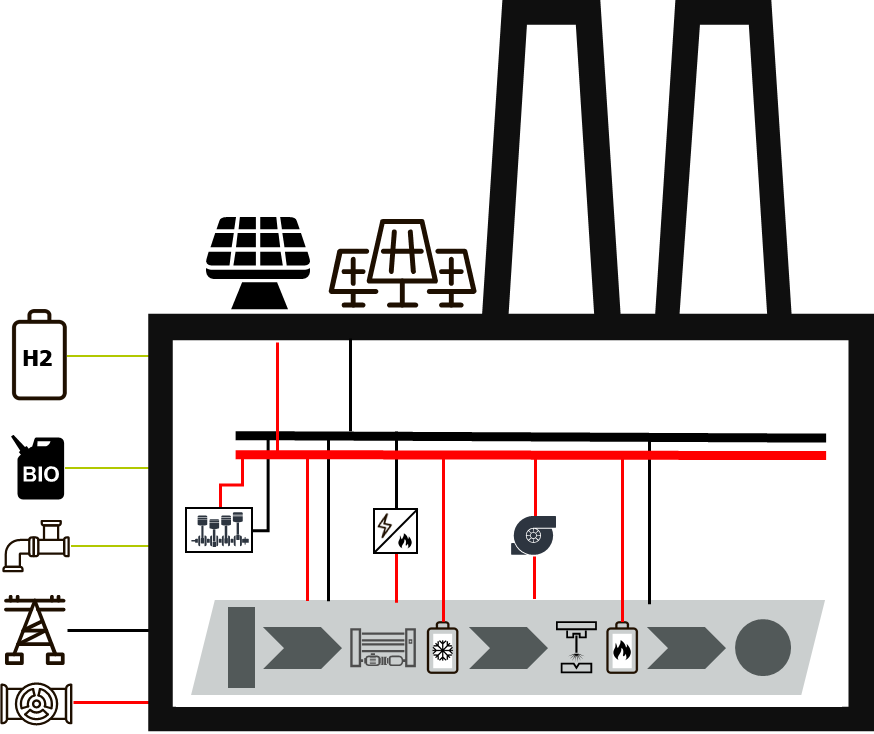

Climate-neutral supply concepts

Economic growth can only be achieved with sustainable measures. The aspect of climate neutrality in the manufacturing industry is becoming increasingly important. According to a survey by the Institute for Energy Efficiency in Production (EEP), a high number of large companies, but also many SMEs, want to become climate-neutral by 2030. A climate-neutral and sustainable energy supply is key to a company's conversion to climate-neutral production. The entire transformation chain must be considered: generation - distribution - storage - reuse. We can optimize your thermal energy supply system.

We help you:

- increase the energy efficiency of processes through thermal simulations

- optimize heat cascades and waste heat utilization

- integrate renewable energy sources & innovative generation technologies

- integrate and design thermal and electrical energy storage systems

- evaluate techno-economic and ecological aspects

- develop control strategies

Energy flexibility

The balance between energy consumption and generation must be ensured at all times. In this regard, companies must also assume responsibility. However, this is not only associated with hidden challenges but also with opportunities.

By exploiting the potential for greater energy flexibility in factories, companies can optimize their energy supply costs. For example, they can increase their own consumption of renewable energy, cut energy supply costs by reacting to fluctuations in energy prices, or market flexibility potential as a system service.

We help you:

- identify and assess the energy flexibility potential of your industrial systems

- plan, design and evaluate thermal storage systems

- design concepts for hybrid production machines

- develop electrification concepts

Use of hydrogen

In order to decarbonize industry, a holistic approach is called for. The full use of renewable energy must be given top priority. According to numerous studies, in the medium to long term the flexible energy carrier hydrogen is seen as being the key to integrating renewable energies into the electricity, heating, transport and industry sectors.

Through the possibilities of storage, transport and conversion it offers, hydrogen can contribute to decarbonization while helping to make electricity demand more flexible at the same time. Already today, the technological maturity of many hydrogen technologies such as electrolysers and fuel cells is very advanced. Despite this, their use is not widespread due to high costs and low awareness.

The aim is to establish hydrogen technologies on the market. To achieve this, economical applications for a wide range of users must be demonstrated. These are seen in the combined use of hydrogen. Therefore, its usage in industrial energy supply, mobility and other applications is increasingly in focus.

We help you:

- identify substitute processes

- plan, design and evaluate potential processes

- design concepts for production machines

- develop business cases

Sector coupling

To achieve a climate-neutral energy supply solely from electricity, industrial processes must be networked and intelligently controlled. In addition to integrating a company into its own ecosystem, it must also be coupled to the energy market and the intelligent energy system. Sustainability and digitalization are thus merging to become the biggest change driver in industry.

A key element in this context is sector coupling. In industry, sector coupling is understood as linking electrical, thermal, mechanical and chemical consumers and generators. Electrifying non-electrical energy sources, such as heating and cooling, plays an important role here.

We help you:

- examine the coupling and efficiency measures of your processes and energy generation

- plan, design and evaluate your energy system with regard to sector coupling

- couple thermal, mechanical and chemical consumers to the energy market

- develop electrification roadmaps for a purely electrical energy supply

- use cross-sectoral applications and technologies

- network processes and IT