Data fusion for non-destructive testing methods for fiber reinforced plastics

In Short

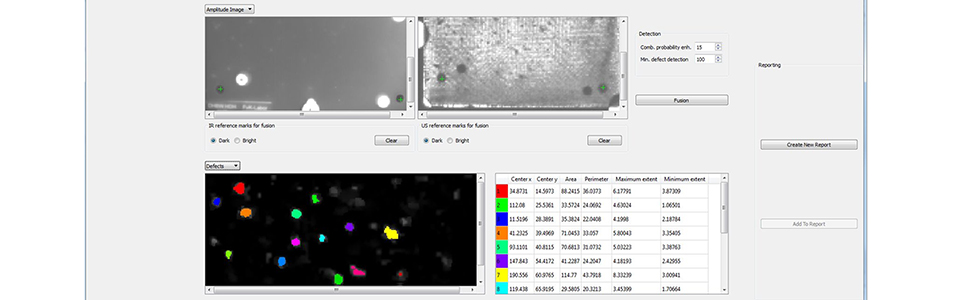

A software platform was developed for the joint evaluation, display, and fusion of data from the non-destructive testing methods of computed tomography (CT), ultrasonics and thermography. The focus was on testing carbon (CFRP) and glass fiber reinforced plastics (GFRP).

In Detail

In the EU project QualiFibre, the non-destructive testing methods of CT, ultrasonics and thermography were examined. The focus was on testing fiber reinforced plastics (FRP), especially CFRP and GFRP. Each of the mentioned testing methods has its specific advantages and disadvantages. To generate the maximum possible added value, a software platform was developed for the joint evaluation, display and fusion of the data generated by the methods.

To evaluate the three-dimensional CT data, the platform includes algorithms for detecting defects and for analyzing fiber orientation and porosity.

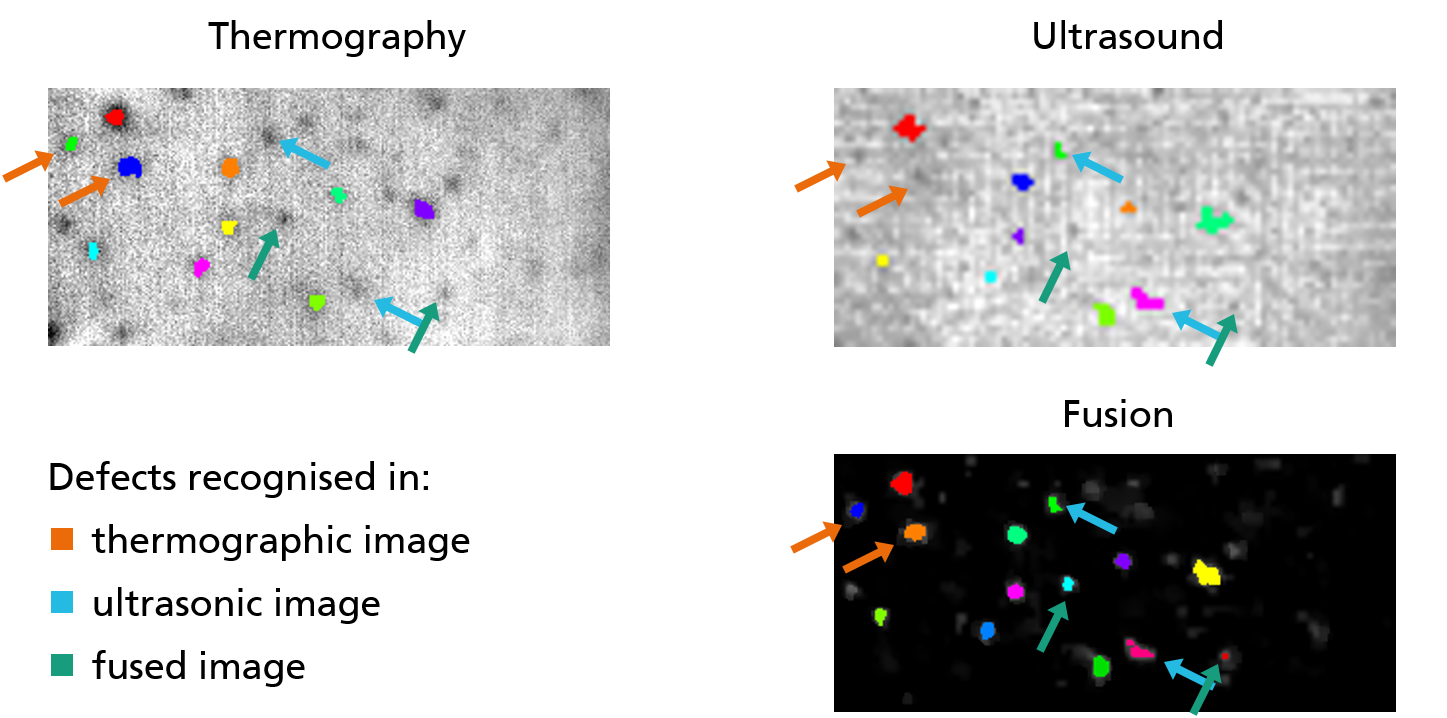

The two-dimensional ultrasonic and thermography data are also automatically analyzed to detect defects. Since some defects are not included in both image types, a method for fusing data was developed. This makes it possible to obtain the maximum amount of information from both inspection techniques and to increase the overall defect detection rate.

Although the developed techniques were designed for FRP, they can still be transferred to a variety of other material types.

Insights into the project