From screen printing to inkjet printing – digital processing of industrial inks

In Short

Together with Ritzi Industriedrucktechnik GmbH, we investigated whether screen printing inks can be processed digitally using inkjet technology. Rheological analyses and initial printing tests confirmed the feasibility of this approach with the aim of transferring these materials to digital manufacturing processes.

In Detail

The transfer of material systems used in classic printing processes, such as screen printing, to inkjet printing opens up new fields of application for the materials. This allows manufacturing processes to be made more flexible and efficient. The aim of the ZIM feasibility study was to process screen printing inks digitally using inkjet printing.

Project partners and technical implementation

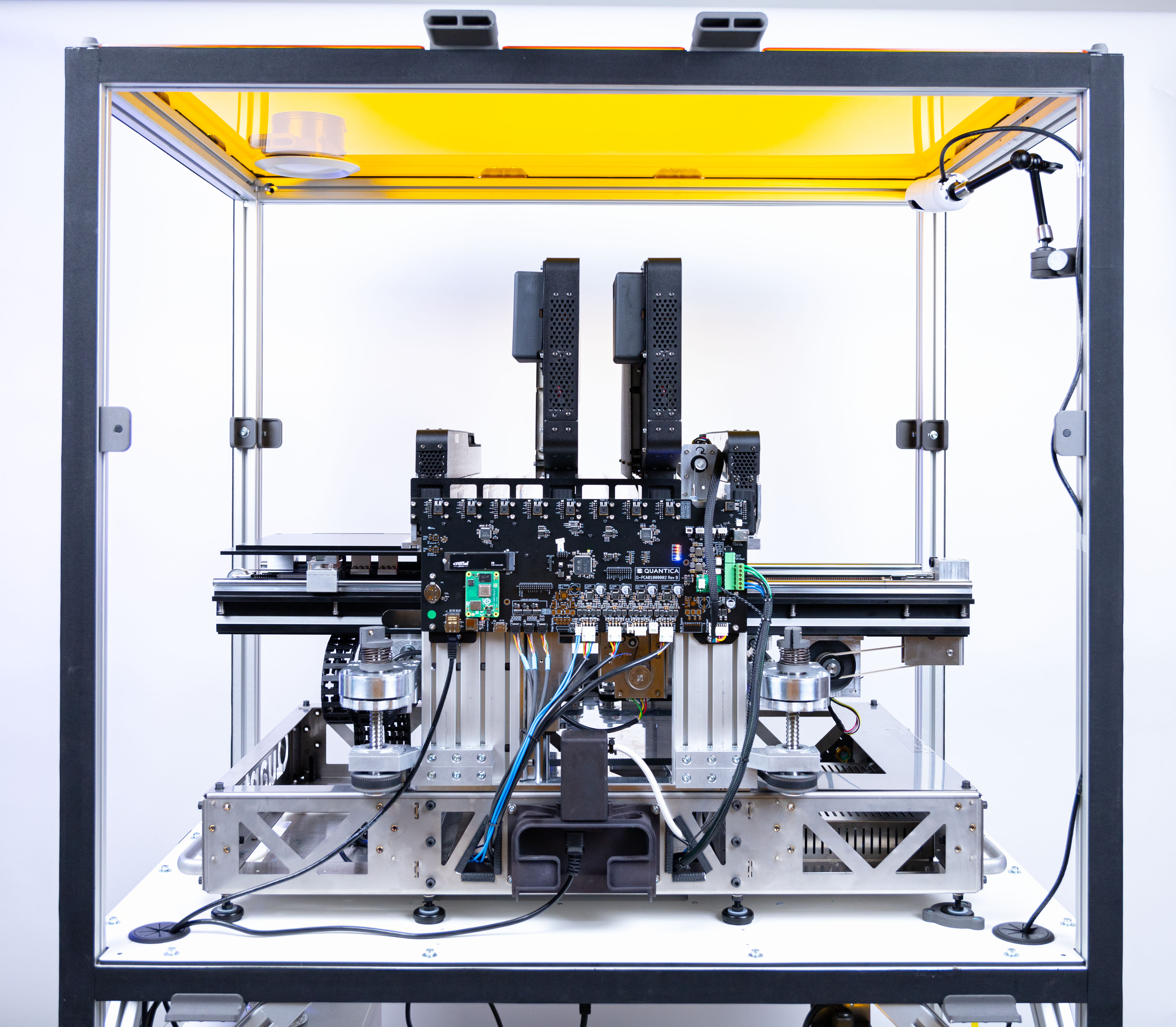

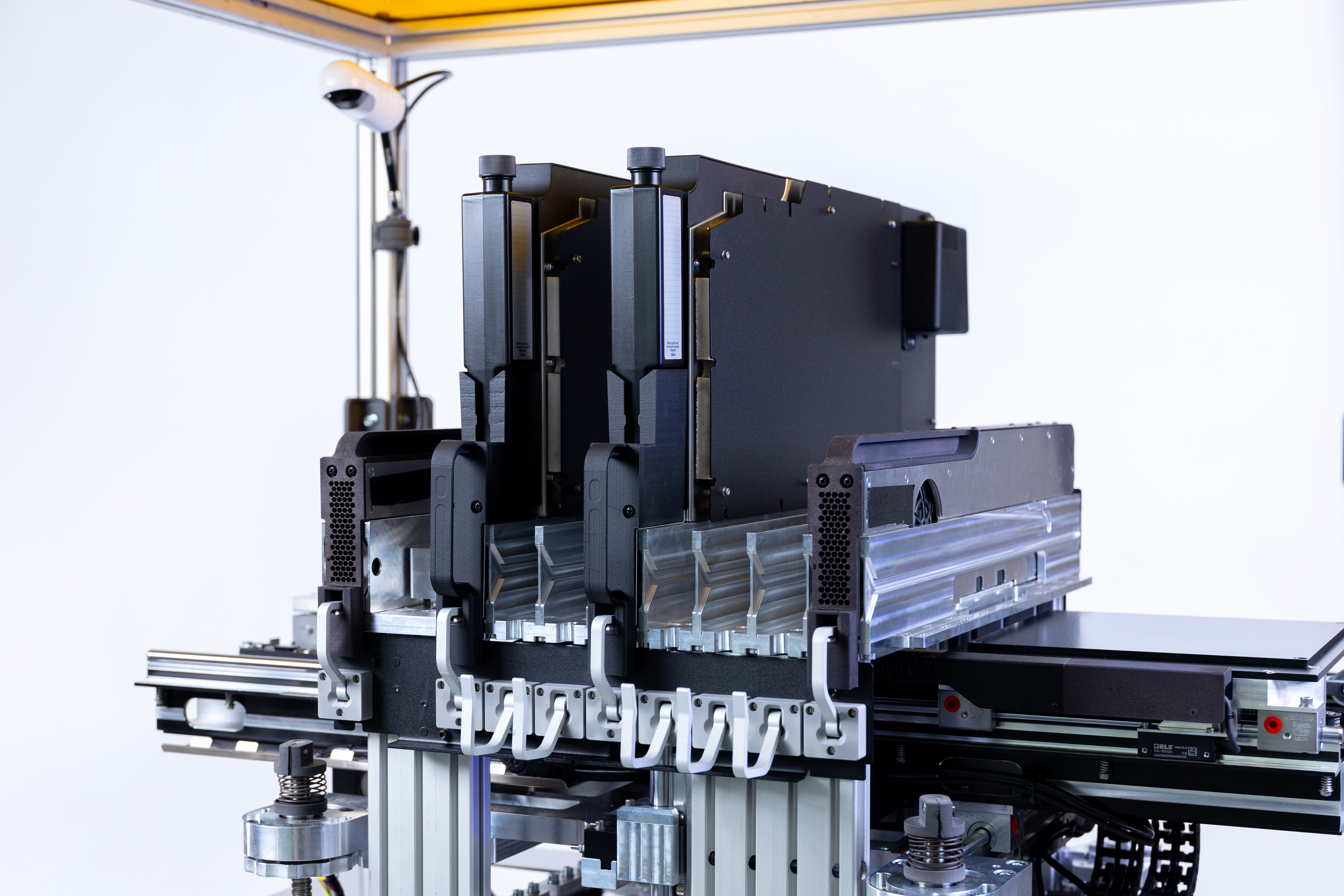

Ritzi Industriedrucktechnik GmbH is a specialized printing service provider for customers in the automotive and medical technology industries. As part of the joint project, reference screen printing inks from Marabu GmbH & Co. KG were used, which enable customer-specific colors as spot colors and are already approved for regulated applications. Until now, these materials have been processed exclusively in mask-based processes such as screen printing and pad printing. Together with Marabu and printhead manufacturer Quantica, the project investigated whether these high-viscosity screen printing inks could also be applied digitally using inkjet.

Solution and role of Fraunhofer IPA

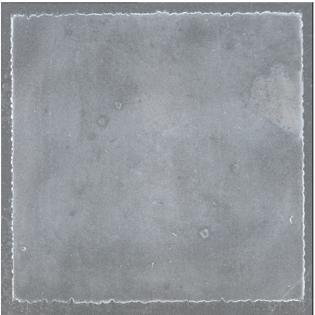

The aim was to combine the material diversity and specific properties of screen printing inks with the fast, contactless application of the inkjet process. The challenge here is the narrow process window in inkjet printing, which is not designed for the properties of conventional screen printing inks. Fraunhofer IPA analyzed key material properties such as viscosity, surface tension, particle size, and compatibility with the print head. Through targeted adjustments, such as dilution, the inks were made suitable for inkjet printing. The results formed the basis for initial successful printing tests at Quantica, in which a screen printing ink characterized by the IPA could be digitally printed. Building on this, development steps for ink stabilization were defined, which serve as the basis for the further development of the inkjet processability of the materials. This innovation paves the way for innovative digital printing solutions in industry.

Customer quote

»Our customers use certified materials that have been specially developed for technical applications and meet high requirements in medical technology and the automotive sector. Until now, these materials could only be processed using screen or pad printing. At the same time, we are noticing an increasing shortage of skilled workers in the field of screen printing training. In addition, the requirements for flexibility and individual labeling are increasing, for example through variable print images or serial numbers. The ability to process existing screen printing inks digitally would be a decisive step for us in meeting these requirements efficiently and economically in the future.«

Marius Ritzi, Managing Director, Ritzi Industriedrucktechnik GmbH