Evaluating paintability by means of fluid-dynamic simulation

The customer

Audi AG is a German automobile manufacturer based in Ingolstadt in Bavaria that became a member of the Volkswagen Group in the 1960s. Since the 2000s, the company has been regarded as a manufacturer of premium vehicles.

Initial situation

Many functions cannot be tested for their suitability until the prototype vehicle has been built. At this point, however, it is virtually impossible to make any changes to the design. If problems associated with the painting process only now become apparent, corrections and expenses will delay the planned completion.

Solution

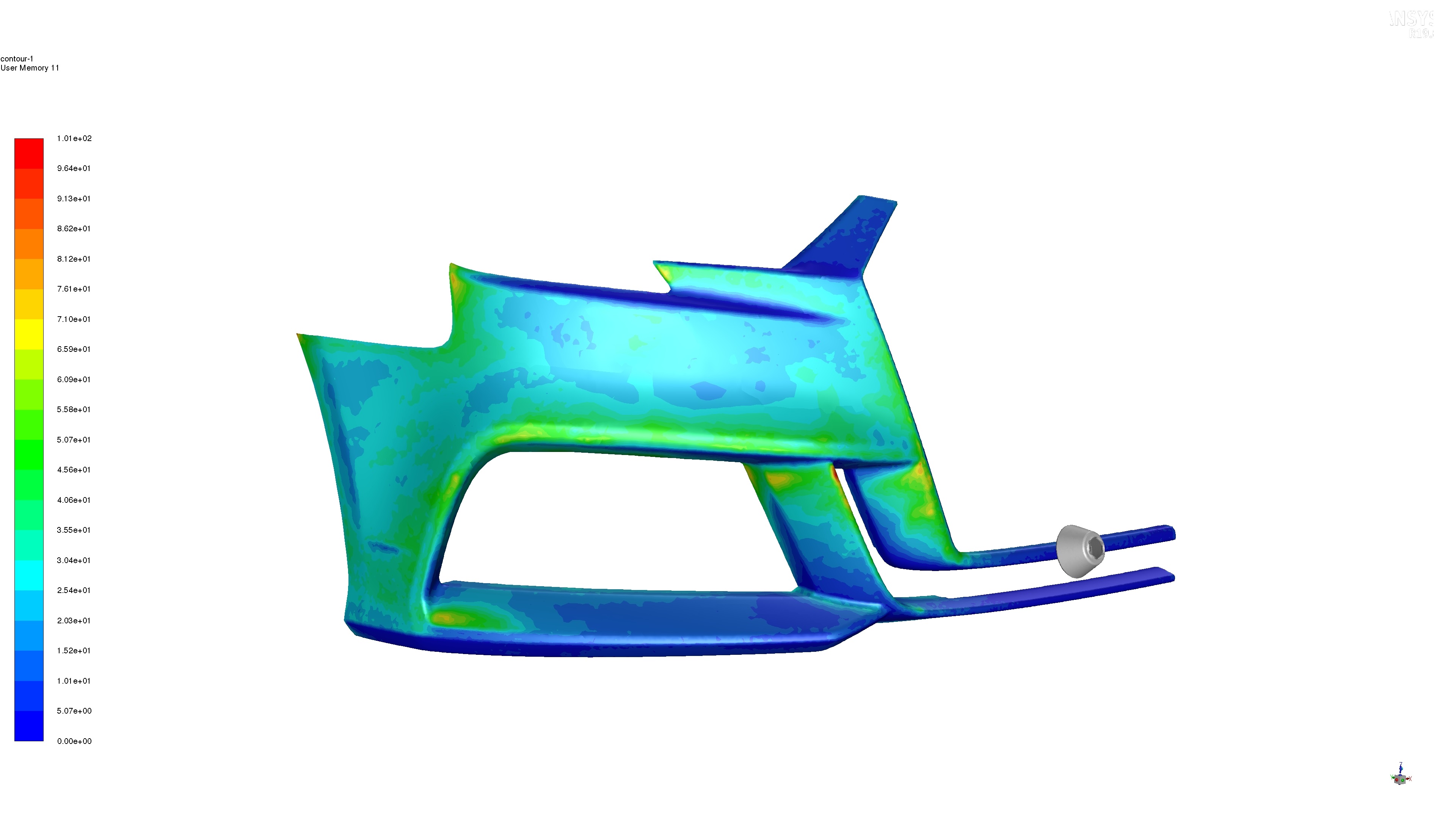

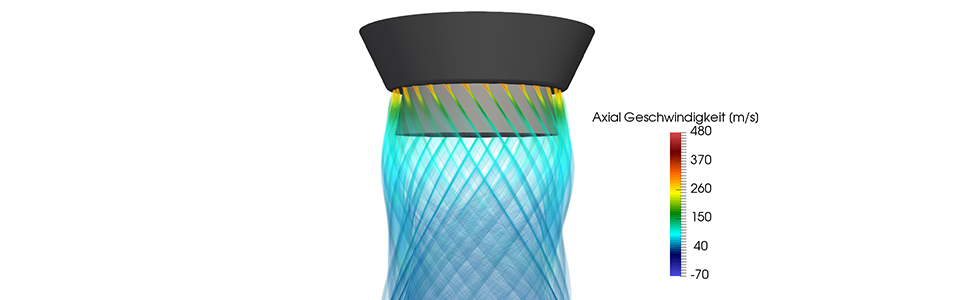

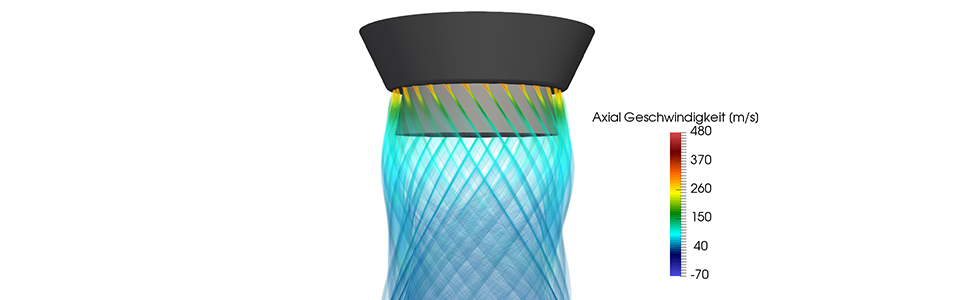

In this project, fluid dynamic simulations were carried out on a 3D model of a fender to find out where problem areas (undercuts, dynamic pressure fields) for electrostatic coating processes are located.

Advantage

During the design phase, structural modifications can still be made in order to optimize paintability. This saves later tool changes or the resulting additional costs for special processes.

- Shorter development process

- Costs for design/process changes are eliminated

- Faster commissioning