Material substitution in the coating process

Sustainable coatings with no compromises on quality

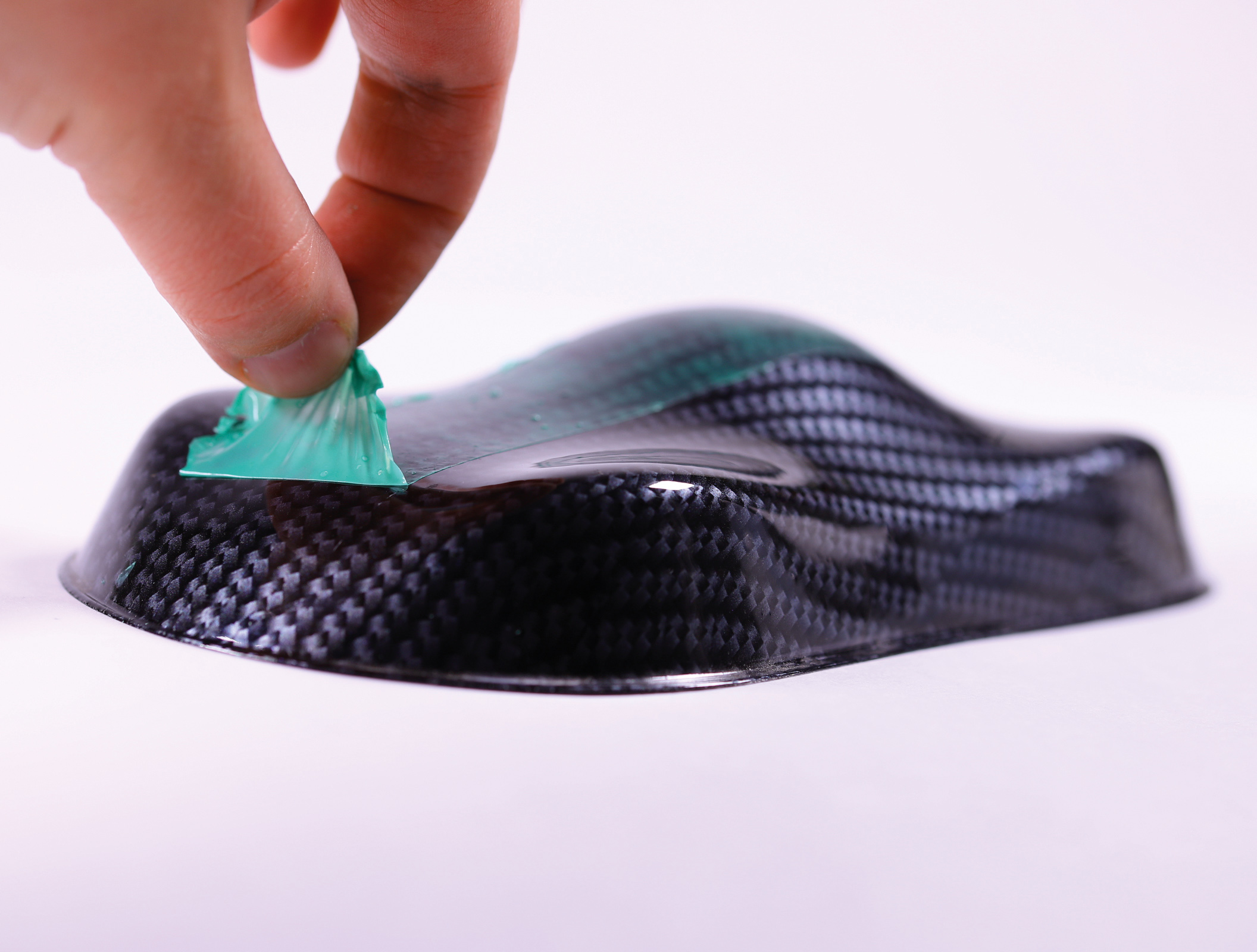

Material substitution in the coating process offers companies a future-proof way to use sustainable materials and replace hazardous substances without compromising on quality or performance. Demand for environmentally friendly solutions is growing: REACH-compliant materials and chromium-free or PFAS-free coatings are becoming increasingly important when it comes to meeting environmental requirements and improving safety.

Our material solutions include alternative substances as the basis for pigments, binding agents, filling agents or similar components that replace traditional materials while also meeting requirements for storage life, tribology, hydrophobia, corrosion protection or conductivity of surfaces. Coatings that are free of solvents and VOCs are particularly important as they contribute to a working environment that is clean, harmless to health and free from harmful substances while also significantly reducing emissions.

Fraunhofer IPA can help you to select and implement suitable material alternatives so that you can increase efficiency and achieve your environmental goals in the coating process.

Contact us for free and individual advice on material substitution.

Key topics in the field of material substitution:

- Substitution environmentally harmful substances: Reduction or replacement of toxic and environmentally harmful material in coatings and coating substances, such as heavy metals (chromium, cadmium), environmentally harmful materials (e.g., PFAS — per- and polyfluoroalkyl substances) and volatile solvents with environmentally friendly alternatives, such as water-based paints or bio-based materials.

- Avoidance of environmentally harmful chemicals: Development of replacement substances, such as chromium(III)-based coatings instead of chromium(VI)-based coatings, or non-toxic paints to minimize health risks.

- Reduction of VOC emissions: Water-based and UV-cured coating components as attractive alternatives to volatile organic compounds (VOCs), which are found in paints, lacquers and solvents and are harmful to the respiratory tract and environment.

- Compliance with legal requirements: Development and integration of material combinations to guarantee material compliance in the context of the EU REACH Regulation or RoHS Directive on restricting certain hazardous substances.

- Availability of raw materials: Substitution of costly materials, such as certain metals (e.g., nickel) or substances from fossil-based resources, to reduce the significant dependence on non-renewable raw materials, as well as to lower costs and promote the circular economy through the use of waste products as alternative substances (e.g., chitin, feather keratin or natural starch).

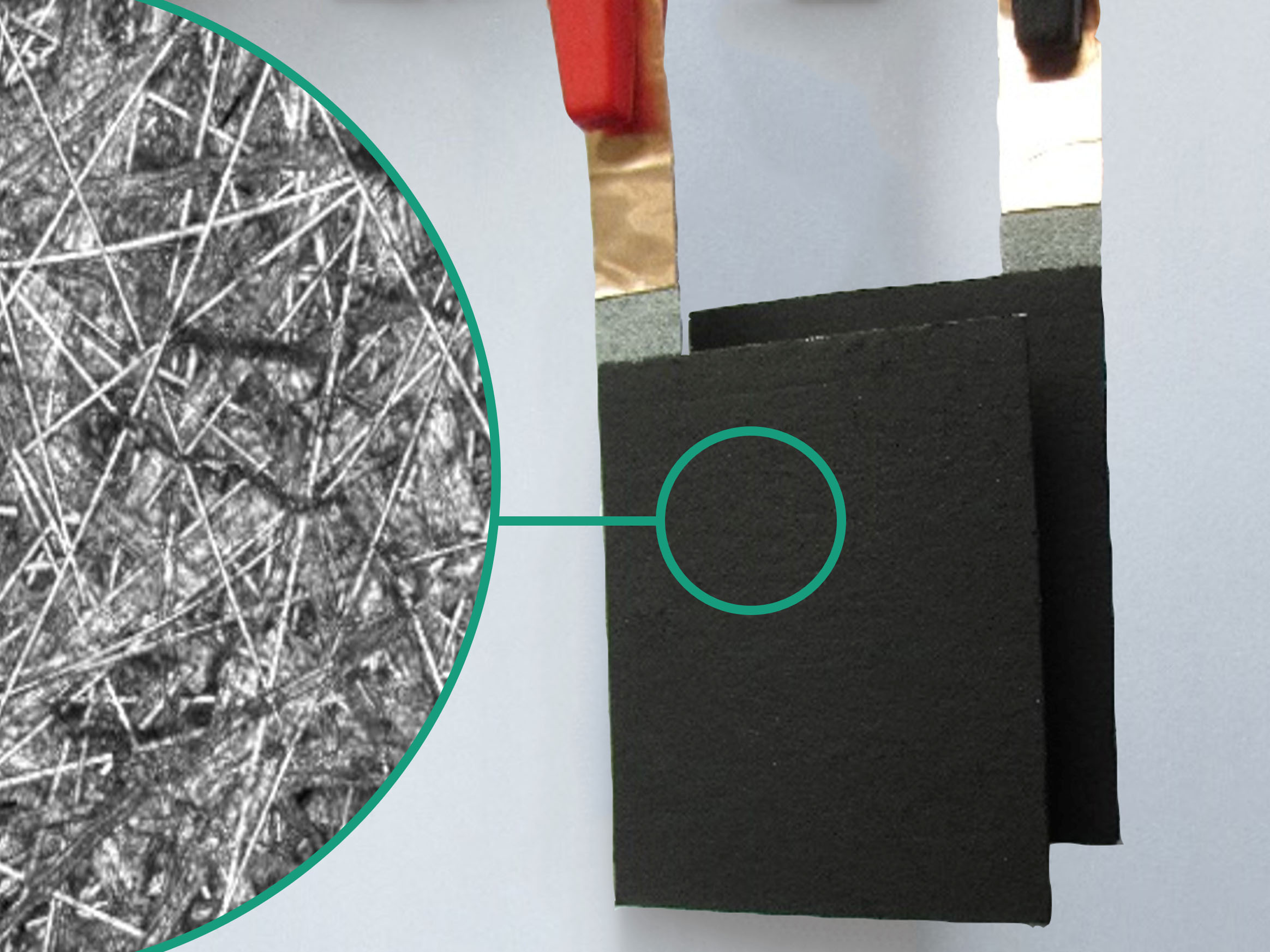

- Nanotechnology and advanced materials: Nanocoatings or materials with special functional properties, such as anti-corrosion, self-cleaning or water-repellent properties, offer new ways to substitute traditional materials. Nanomaterials are an attractive and powerful alternative, particularly when substituting PFAS in coatings.