Motion Analysis for Quality Assurance

Tabbed contents

Expertise

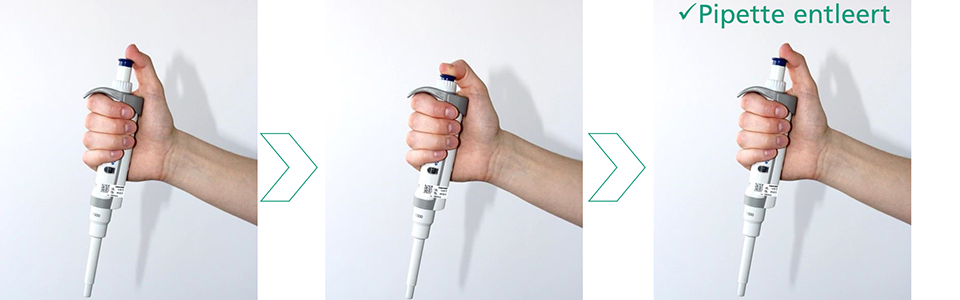

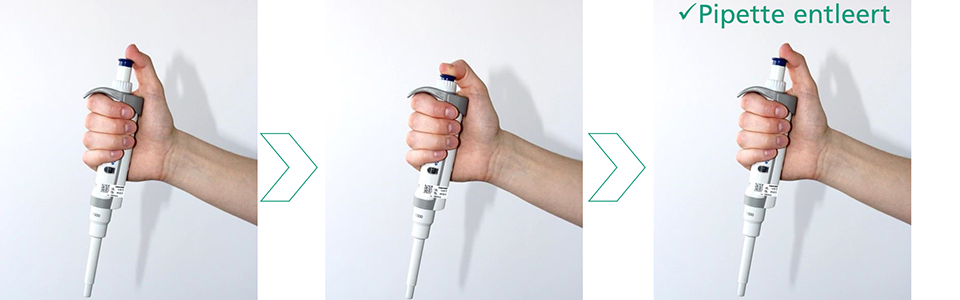

Optical motion analysis has a broad spectrum of application, from assistance with assembly and laboratory processes right up to safety devices. Wherever it is used, optical analysis contributes to quality assurance without the need for any invasive accessories or interaction. By analyzing hand movements in combination with object recognition, correct assembly processes can be identified via direct component analysis. In laboratory environments, by identifying and automatically filing typical motion sequences, this technology assists staff with time-consuming documentation processes and also supplements them. Through tracking movements in critical areas, e.g. where safety or cleanliness are crucial, production errors can be directly avoided. Optical motion analyses of complete production environments incorporate all stationary and moving objects and people within it, thus paving the way for the full realtime digitization of running processes.