Evaluating Joins and Mounted Subassemblies

Evaluating material joins

When assessing material joints with non-destructive methods, active thermography is implemented to identify discontinuities in the joining layer.

Defects in material joins are areas where the joining material is lacking. Thermography can be utilized to evaluate welded, soldered and bonded joins on metallic and non-metallic materials. To analyze the join, the flow of heat normal to the joining plane is the main aspect considered. With a welding spot, for example, the temperature profile above the spot is analyzed and the quality of the join assessed by its development over time and spatial expansion. The temporal and spatial development of the temperature profile can also be analyzed to draw conclusions about the quality of joins made with welding beads

This principle can be also applied to analyze bonded joins: In such cases, mainly the lack of bonded, delamination and “kissing bonds” in the adhesive layer are of interest.

Inspecting force-fit joins

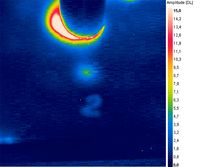

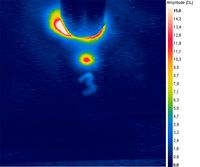

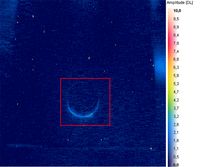

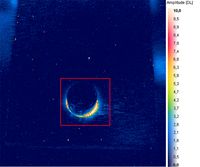

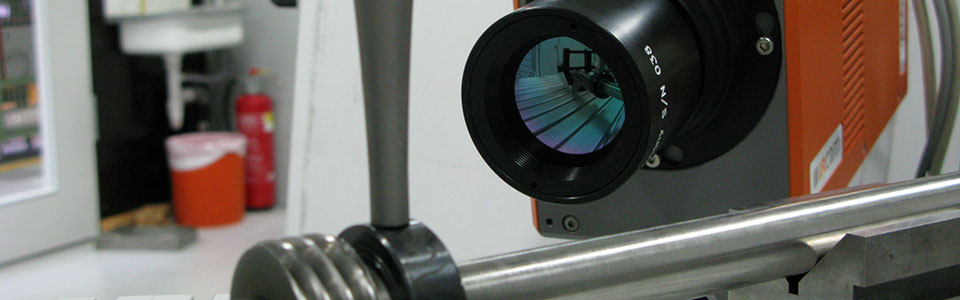

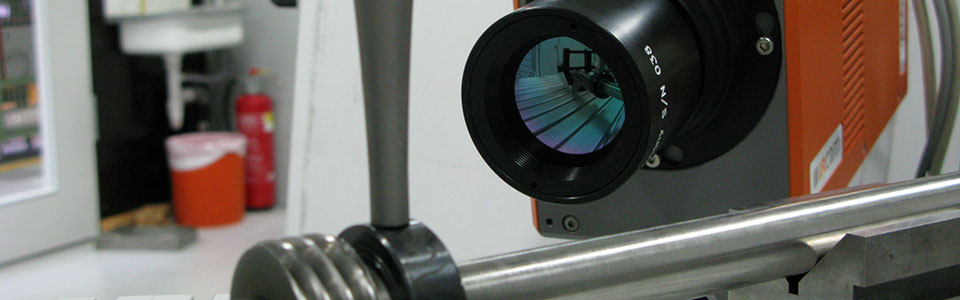

As opposed to searching for discontinuities as is the case with material joins, when analyzing force-fit joins the correlation between the joining force and the thermal behavior of the join is evaluated. The relative movements taking place in the join itself are especially important in this regard because they are often directly related to the development of heat at the joining site. This information can be used to assess the quality of the join. High-intensity ultrasound is the most suitable form of excitation for this, with a frequency being selected to match the mechanical properties of the join. The ultrasound waves applied induce an oscillation mode, causing relative movements dependent on the joining forces to take place in the join. The energy dissipated in this way is converted to heat, which is then detected and analyzed by a thermographic system.

The following example illustrates the analysis of a press fit.

Evaluating assembled components

Plastics in particular have different properties of transparency in the infrared spectrum than in the visual spectrum. This fact can be utilized to identify even hidden defects on mounted subassemblies and is an interesting alternative to x-ray or CT-based methods.

Examples:

- Monitoring the assembly of ballpoint pens

- Foreign bodies in brake plates

- Inspection of weld seams and spots

- Inspection of bonded joins