Thermography for Inspecting Metallic Materials

When inspecting metallic components for defects on or just below the surface, active thermography can be utilized to detect a wide range of flaws. For example, cavities or cracks are selectively identified using electromagnetic or mechanical waves.

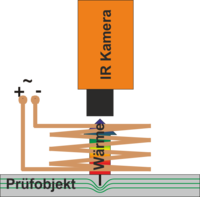

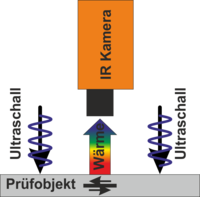

When inspecting metallic components for defects on or just below the surface, active thermography is an interesting alternative to common methods, such as eddy current, magnetic particle and color penetration testing. No consumables are required and the method is easy to automate, even where more complex geometries are concerned. Different excitation sources can be used. These are generally either induction or mechanical oscillation induced by an input of subsonic waves. In the case of metallic materials, these cause a rise in temperature directly where the defect is located, thus functioning selectively in dependence on the defect and assuring easy detection.

Exemplary EU-sponsored project "Trainwheels"

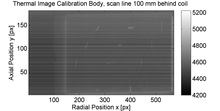

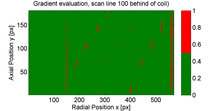

In recent years, railroad safety has become more and more the focus of research in the field of inspection systems and quality assurance. Modern eddy current or magnetic particle testing systems used to recognize defects, such as cracks in the contact surfaces of wheels, cannot be automated and require a lot of effort. The use of induction thermography in this area would not only increase the probability of detection but also enable the inspection procedure to be automated. The method utilizes electro-magnetically induced fields to create eddy currents in the test object. If any defects are present, the current flow is disturbed and the flow density increases. This causes a rise in temperature at the site of the defect, which is then detected by thermography. The aim is to establish this as a standard method for identifying surface defects as a supplement to ultrasound inspection, which is only capable of detecting defects below the surface.

Examples:

- Wheel inspection in rail transport

- Inspection of forged and cast parts

- Inspection of tooth flanks

- Inspection of weld seams