Nano Dispensing Technology

When handling liquids in volumes below one microliter, common pipetting systems are generally insufficiently accurate and need to be supplemented by specific nano dispensing technologies.

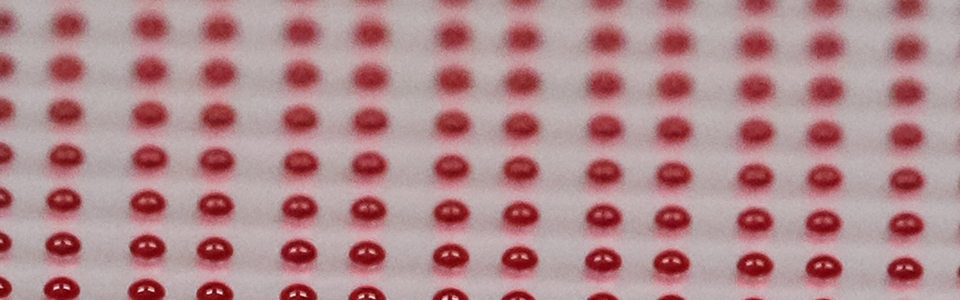

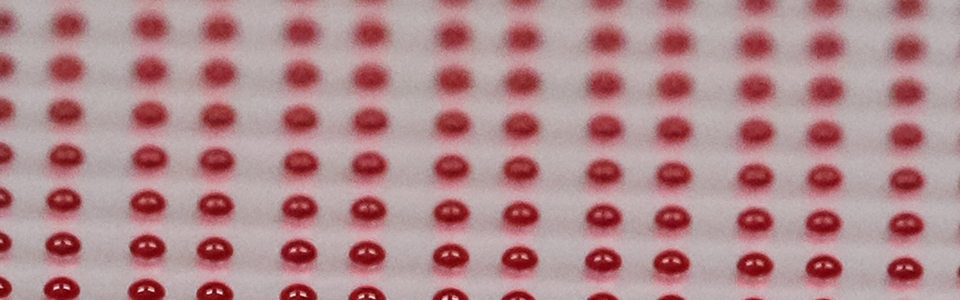

With I-DOT (Immediate Drop on Demand), we have a robust technology that is gentle on resources for performing dispensing tasks in the nanoliter range. I-DOT is an innovative, high-throughput, liquid handling technique for the automated processing of volumes in the nano and microliter range. Drops are dispensed directly contact-free from a 96-well microplate in SLAS format onto any desired substrate. This could be a microwell plate with up to 1536 cavities or any other plate or slide format. With the 8-fold parallel dispensing head, drops approximately 1 nl in size can be dispensed from any single nozzle at a frequency of up to 600 Hz. This enables enormous throughputs to be achieved in a volume range of 10 nl to 1000 nl. So far, I-DOT has been used to perform tasks for miniaturized qPCR as well as to dispense single cells and print highly-viscous media.

As a result, I-DOT is a technology which enables most pipetting steps to be performed fully-automatically - and thus rapidly, cost-effectively and flexibly - in a compact device.

Thanks to the success and the important demand of the I-DOT Technology, Fraunhofer IPA scientists founded the company »Dispendix«.

Application of I-DOT:

- Cell separation and cell printing

- Preparation of samples for qPCR

- High-throughput screening

- Diagnostics

- Manual pipetting tasks

Advantages of I-DOT at a glance:

- No contamination

- Fewer consumables required, lower costs

- Reliable, robust handling of liquids in the nanoliter range

- Source plates made from just about any plastic

- Ability to process high-viscosity liquids

- Blocked nozzles can be easily cleared with a short blast of air

- No complex cleaning steps required