Design of Experiments

Does your production process always run smoothly? Do you know which parameters affect product quality in your production plant?

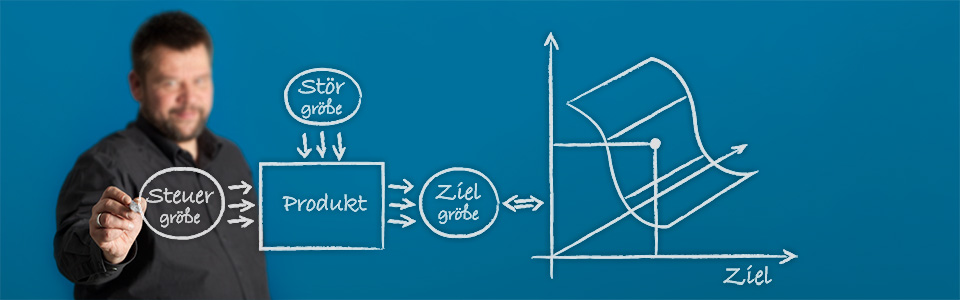

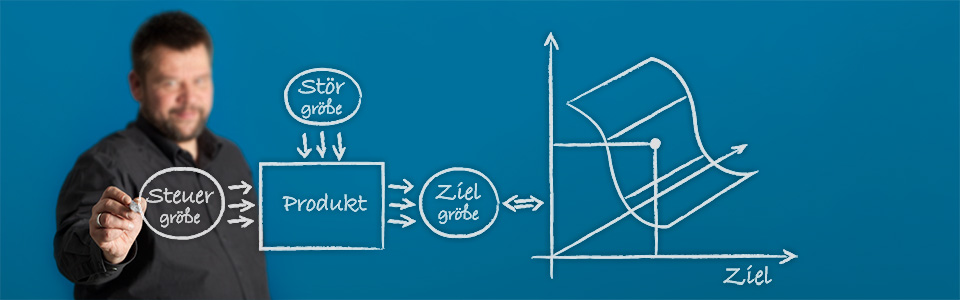

In order for production processes to be stable, there has to be a way to intervene in the event of a discrepancy. A methodical procedure based on Design of Experiments (DoE) supports testing procedures by systematically identifying parameters that affect processes. The end-result is a model of production process parameters. Once the relevant influencing factors (e.g. coolant temperature, ambient humidity) are known, the model can then be used to calculate the parameters required to attain desired target features (e.g. diameter of a workpiece, surface roughness). The application of such a model ensures that product features are generated within specified tolerance levels despite fluctuating external influences (e.g. temperature).

Services

- Methodical identification of parameters influencing the production process,

- Identification of relevant influencing factors (disturbance and control variables) through systematic deduction processes and analysis of preliminary tests

- Elaboration of a test plan with the aid of DoE as well as analysis of tests and derivation of a production process parameter model.