UV sphere makes applying paint quick and easy

Cars, furniture, electronic enclosures – all sorts of things are painted. However, the usual paint drying processes have attracted criticism on account of high energy consumption. A new refined system reduces energy requirements, sustainably protects the environment and drastically shortens cycle times.

There are two options when it comes to curing painted components: Either you can dry them with warmth, which takes a relatively long time and requires a lot of energy, or you can irradiate them with UV light. However, there are limitations to the usual UV curing methods for industrial applications if the component has a complex shape. In this case, the light source or the part must be readjusted several times, and even then not all surfaces are optimally reached. A consortium of companies and institutes have now developed a system that makes this redundant, works quickly and saves energy. It is based on the following principle: if you beam light into the inside of a sphere, it is almost perfectly scattered by the multiple reflections off the walls. If the part is placed inside a sphere, all of its surfaces receive the same amount of UV irradiation, without the effort of adjusting the part.

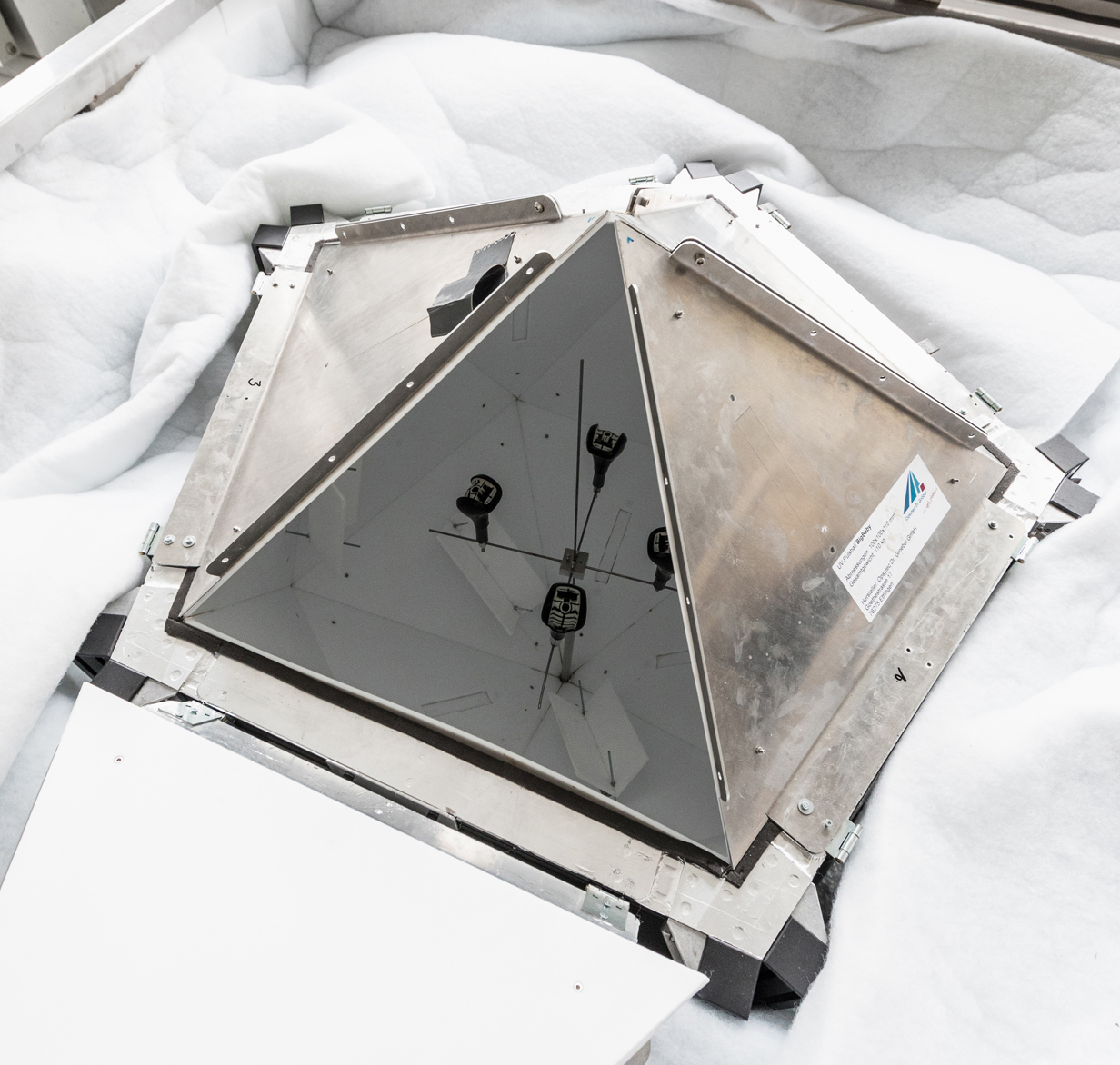

Sphere made from 20 triangles

The engineers did not use a perfect sphere, instead using an approximate spherical shape made up of 20 flat triangles, which is easier to manufacture. The internal surface is made from Teflon, which reflects over 80% of the radiation and is also dirt-repellant and UV-resistant. The UV light sources weren’t the conventional mercury vapor lamps either; they were innovative high-performance LED spotlights that use very little energy, have short warm‑up times, can be turned off quickly and have a long useful life. Alfred Feilen, CEO at Easytec confirms: »The UV LED lamps have particularly advantageous properties for integration into the UV sphere. The small dimensions, high optical output density and quick cyclability makes them the ideal radiation source for this application.«

Cures in seconds

The prototype that has now been developed meets all expectations. Rainer Röck, the inventor and patent holder, is delighted: »We even placed 3D components that have several layers of paint in the patented UV sphere, turned on the high-performance UV LEDs and in the space of a few seconds of UV pulsing, the paint layer cured evenly. And that goes for components with complex shapes, indentations and holes too. The great thing about this is that neither the UV rays nor the components need to be moved or adjusted, regardless of the size and shape of the components.«

Profile

The »UV sphere pulse system for 3D paint curing« project was supported by the Federal Ministry for Economic Affairs and Energy and spanned three years. In addition to the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Durst Lackier- und Trocknungsanlagen GmbH, Easytec GmbH, Institute of Industrial Manufacturing and Management IFF of the University of Stuttgart, Opsytec Dr. Gröbel GmbH and Ritzi Lackiertechnik GmbH were all also involved in the project.