Milestone in circular saw technology

Researchers at Fraunhofer IPA have developed an innovative procedure for internally cooling disc-shaped, rotating cutting tools. With the support of pertinent mechanical saw and sawing tool manufacturers, the result is a lightweight, upgradable and cost-effective concept that represents a milestone in the evolution of circular saws.

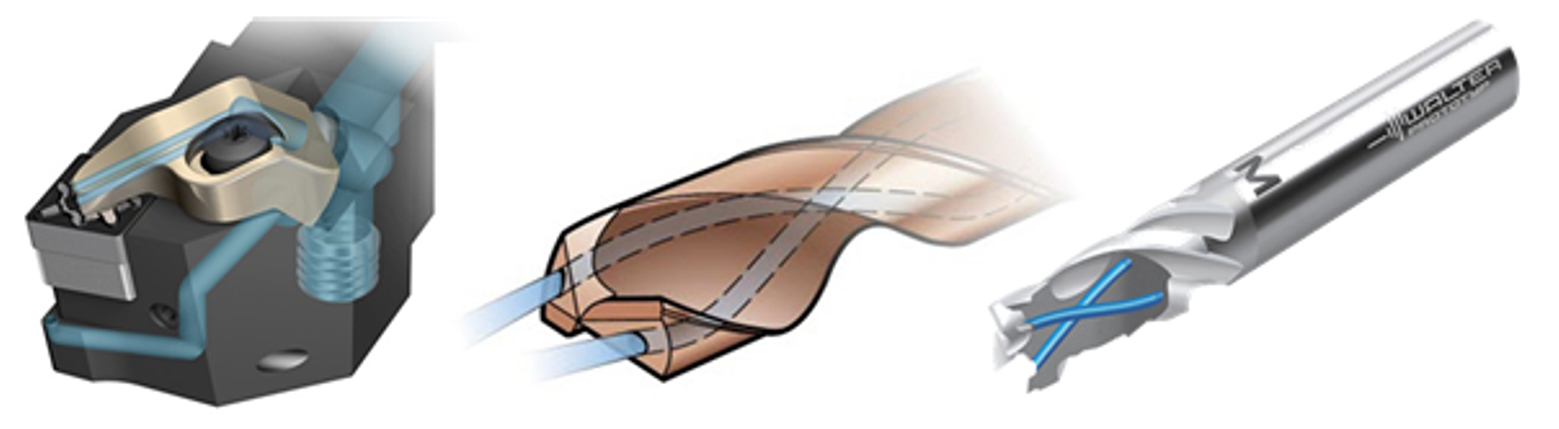

When cutting materials, high temperatures occur at the site of the cut that can negatively affect the cut and the workpiece, as well as shortening the tool’s service life. One possibility for directing the cooling lubricant at the cutting area is internal cooling within the tool, which sees the cooling lubricant directed through internal channels in the tool directly to the cutting area. While this process has been used successfully for lathes as well as milling, grinding and drilling tools for some years now, there is no comparable internal coolant system specifically bringing value added to cutting workpieces made from high-alloy stainless steels, and titanium-based or nickel-based alloys.

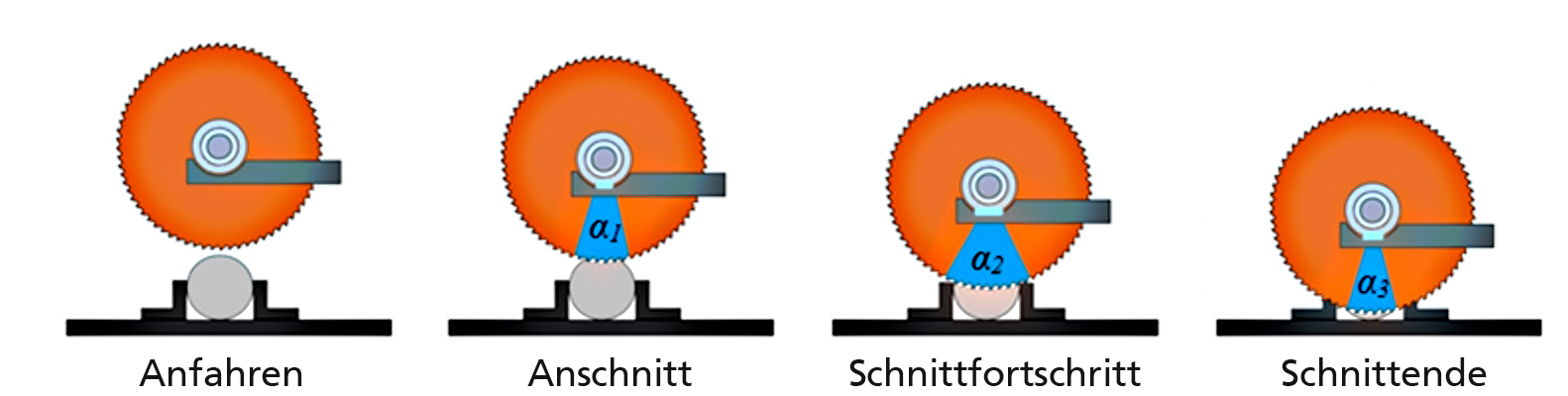

Now, for the first time, Fraunhofer IPA has been able to integrate channels into the saw blade, meaning that internally cooled tools can be created. The idea to adapt internal tool cooling systems to include disc-shaped tools such as circular saw blades has enormous potential and has met with a great deal of interest in the industry. One significant technological advantage is the possibility to process materials that were previously not suitable for cutting with a saw. Fraunhofer IPA project leader Christoph Birenbaum, an Engineering graduate, explains: "The project idea with this innovation appeals to companies as end users that use high-strength stainless steels. Using cooling lubricant directly at the cutting area not only lubricates the sawing process but also reduces heat, meaning that longer working times and above all higher cut speeds can be achieved. This increases productivity significantly."

Mechanical saw manufacturers also benefit from the innovation due to the appreciation of their machinery, and sawing tool manufacturers due to the larger product portfolio. In addition, there is huge savings potential in terms of the cooling lubricants used. For end users, this reduces additional costs and environmental impact. Exploratory talks are currently taking place to develop the internal cooling system for series production.