Manufacturing concept and automation and cost analysis at STEM SAS

Scalable and future-oriented production of membrane-based exchangers for air and water treatment in a green tech start-up

In short

The aim of the project was to create a basis for STEM SAS and its investors to make decisions regarding future developments. Challenges included: best-fit manufacturing system (short/mid term), product cost forecasts by system (short/mid term), automation level during ramp-up, and outsourcing strategies.

Fraunhofer IPA supported the project with a structured approach that included product analysis, development of manufacturing and assembly concepts, design for automation, evaluation of automation potential, and outsourcing strategy. The team defined short- and mid-term manufacturing and assembly concepts, assessed the product design for automation readiness, and conducted cost analyses of future scenarios and key drivers to guide decisions on which processes to outsource. In addition, for different outsourcing strategies the cost scenarios were adapted. The results were summarized in a roadmap that includes the investment costs for the long-term scenario.

In detail

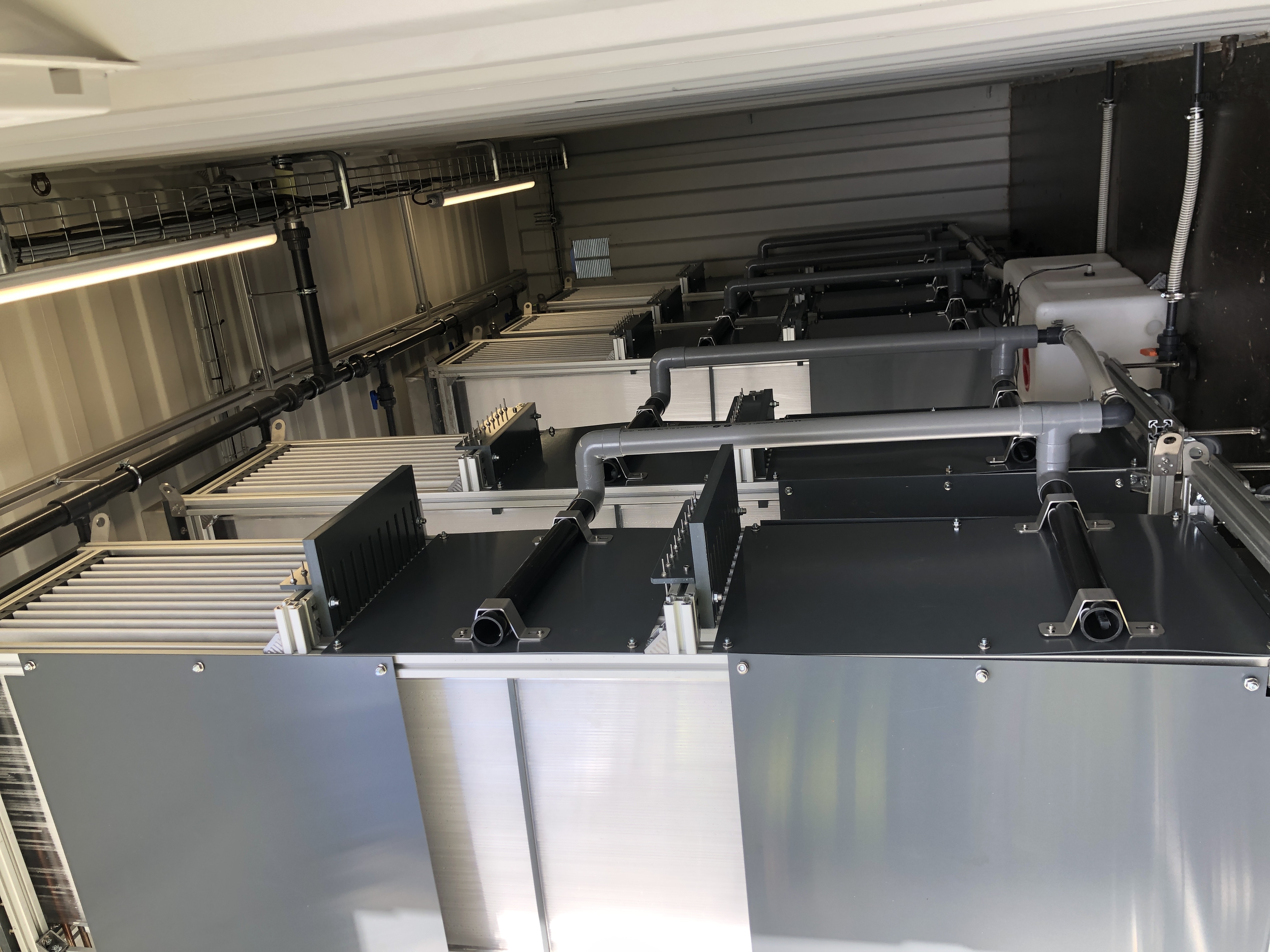

STEM Technologies is a young start-up focused on developing advanced membrane-based solutions for air and water treatment. The company faces challenges typical for emerging businesses, such as scaling production and establishing market presence. Their innovative products include membrane contactors for efficient gas transfer and membrane bioreactors for wastewater treatment. Committed to sustainability, STEM Technologies aims to offer environmentally friendly solutions while optimizing processes for improved efficiency and reduced environmental impact. Despite its challenges, the company is positioned as a key player in the membrane technology sector, driving innovation in the industry.

Fraunhofer IPA analyzed STEM SAS's product portfolio. Assembly priority graphs were created for each product, considering current manufacturing and assembly processes, as well as possible degrees of freedom. The need for workstations or worktables, as well as the requirements for their equipment, were determined based on work content and planned quantities. Typical production key performance indicators were considered when designing the manufacturing concept. Based on this, several layout variants for the manufacturing concept were developed and evaluated, taking future development scenarios into account. A preferred variant was then selected.

Additionally, a design for automation approach was used to evaluate the individual product components to make future production as efficient and assembly friendly as possible. An automation analysis compared current and planned future levels of automation, identifying promising processes for future automation solutions. Furthermore, process steps and parts were identified for which the make-or-buy question will need to be addressed in the future, given the expected growth in unit numbers.

A cost assessment was also carried out, evaluating and challenging individual parts and components in terms of cost. This was done primarily to enable future cost developments to be estimated as accurately as possible, and to allow necessary measures to be incorporated into planning at an early stage. This supports the future development of STEM SAS based on facts and sound decision-making principles.

Customer quote

»Fraunhofer IPA’s analysis helped us convince our investors by building confidence in our business plan and product cost estimations. With the results and the roadmap, we now have a scalable manufacturing strategy for the coming years.«

David Poizat (Directeur Général)