Accuracy improvement of cable-driven parallel robots by measuring cable lengths with laser distance sensors (DCLM-Sensors)

In short

The accuracy of cable robots is often negatively impacted by effects such as elongation of cables due to their inherent elasticity. To combat this effect, a method based on the use of laser distance sensors was developed at Fraunhofer IPA to correct the cable lengths and thus improve the cable robot accuracy.

In detail

In general, cable robots have to be very accurate, for example when printing 3D concrete structures or assembling facade elements. Effects such as elongation of the cables due to their inherent elasticity or creep in synthetic fiber cables can lead to inaccuracies when calculating the length of the cables. This, in turn, impairs the accuracy of the end effector. Payloads on the end effector can further exacerbate these effects.

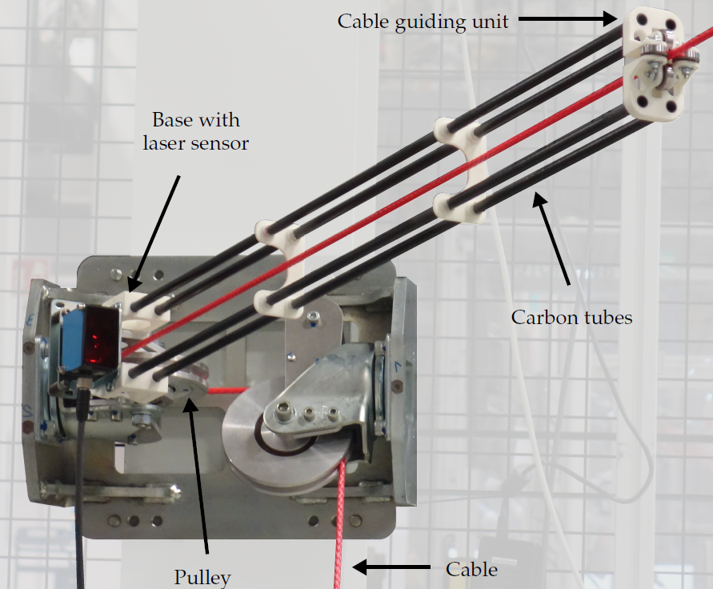

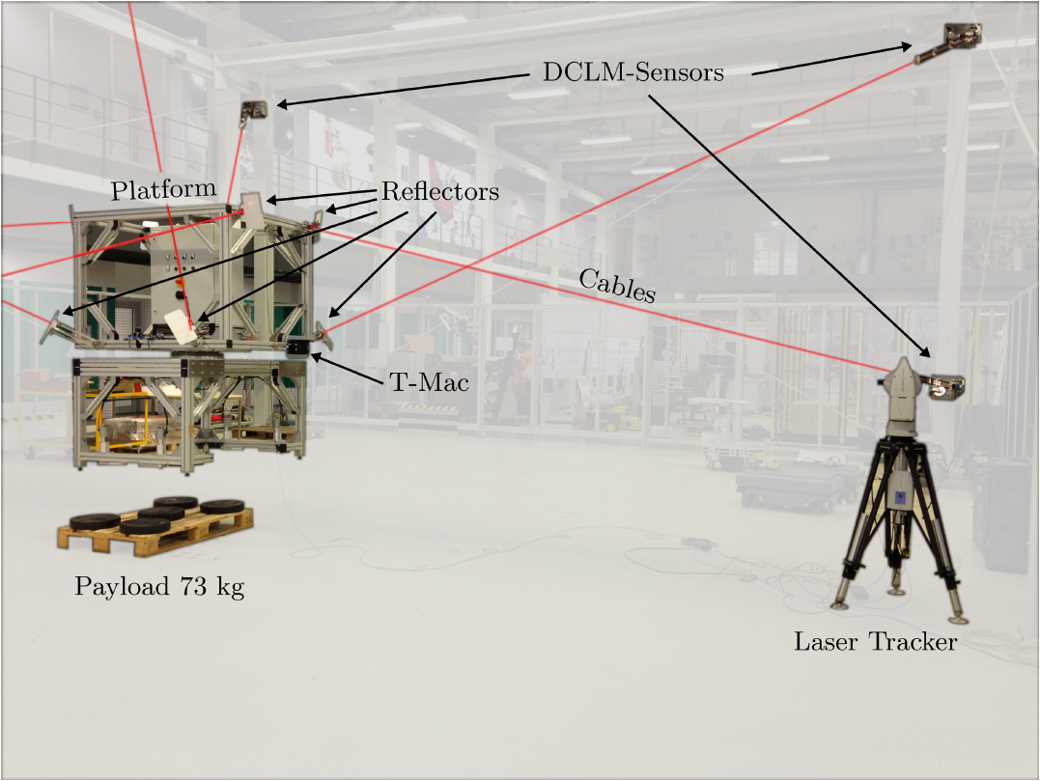

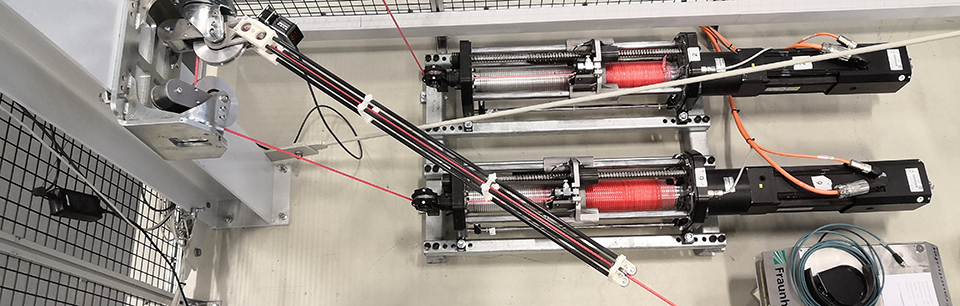

To compensate for inaccuracies due to such cable length errors, a sensor for directly measuring the length of cables has been developed at Fraunhofer IPA (hereinafter referred to as Direct Cable Length Measurement Sensor, or DCLM-Sensor for short). The DCLM-Sensor is based on laser distance sensors and can be mounted on the cable robot’s pulleys. A cable guide ensures that the laser beam of the DCLM-Sensor is aligned parallel to the cable. At the other end of the cable, which is connected to the cable robot platform, there is a reflector. This external sensor system allows the distance between the sensor and the reflector, and thus also the length of the cable, to be accurately measured.

To evaluate the sensor system, all cables of the IPAnema 3 demonstrator were fitted with a DCLM-Sensor. The cable lengths measured by the eight DCLM-Sensors were fed into the cable robot’s control system and used to compensate for cable length errors. To measure the increase in accuracy, a trial was conducted to measure the accuracy of the pose with a laser tracker (Leica AT960). Compared to the cable robot’s standard control system, the error compensation achieved by the DCLM-Sensors results in an accuracy improvement by up to 86 percent. The installation of DCLM-Sensors on cable robots also simplifies the calibration of the home pose because the absolute lengths of the cables can be measured. In further research work, there are plans to use the sensors to optimize the geometrical parameters of cable robots.

If you are interested in a more accurate cable robot, you are welcome to inspect the technology on our IPAnema 3 demonstrator. The sensor system can also be integrated into your cable robot within the scope of a project.

Insights into the project

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyDCLM-Sensor mounted on a pulley of the IPAnema 3 cable robot during a trajectory run.