Analytics and Material Testing

Tabbed contents

Competences

The Analytics and Material Testing Group investigates damage cases, conducts research projects and supports industrial partners, experts and cooperation partners to characterize and to evaluate raw materials, coating materials, coatings and plastics. In our laboratories, we carry out damage analyses of defects on coatings or substrates as well as we investigate lacquer application on substrates (materials).

Key areas of expertise:

- Chemical-physical analysis programs to characterize/identify materials and to determine temperature- or time-dependent and stress-related material changes

- Damage analysis, clarification of damage mechanisms, analysis of coating defects, adhesion deficiencies or failed batches, competitor comparisons, analytical support in expert reports, identification of ingredients in formulations, comparative analyses, verification of thermal parameters, visual (microscopic) imaging of defect patterns

- Selected analysis methods using infrared spectroscopy and Differential Scanning Calorimetry (DSC) are accredited according to DIN EN ISO/IEC 17025. In addition to paints, paint components and coating systems, we also conduct surface analyses on composite plastic systems, fibers, operating materials, machine parts (contamination), etc.

DAMAGE ANALYSES

Clearly identify the causes; detect and avoid paint damage

In the Department of Coating Systems and Painting Technology, the development and application of paint-related analytical testing methods is a key area of expertise. Our activities focus on organic coating materials, their material properties and application fields. These range from coatings for wood through wall paints to functional and decorative paints for the automotive industry.

There are many causes of paint defects in decorative and functional coatings. Among others, these include curing deficiencies, incorrect mixing ratios for 2-component paints, contamination by substances that impair wetting properties (LABS), the inclusion of foreign particles, and defects in substrates. In some cases, at least two unintentional changes of the system can occur simultaneously. Solvent retention is in many cases a serious problem. Sometimes, such effects would not cause any damage on their own, but in combination they can be responsible for major failures. Since the reason for the defect in each case is unique, a tailored approach to troubleshooting is required. In our laboratories, we have an extensive range of testing methods and equipment at our disposal:

- Infrared spectroscopic tests: for characterizing binders and fillers, detecting surface contamination, infrared microscopy

- Thermal analytics (DSC, TGA, DMA)

- GC-MS: analysis of volatile components

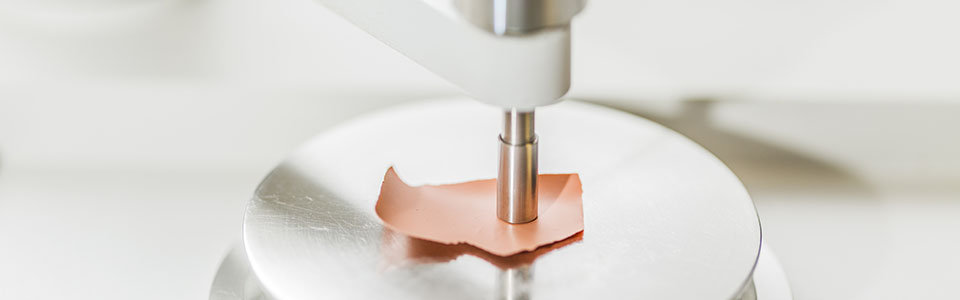

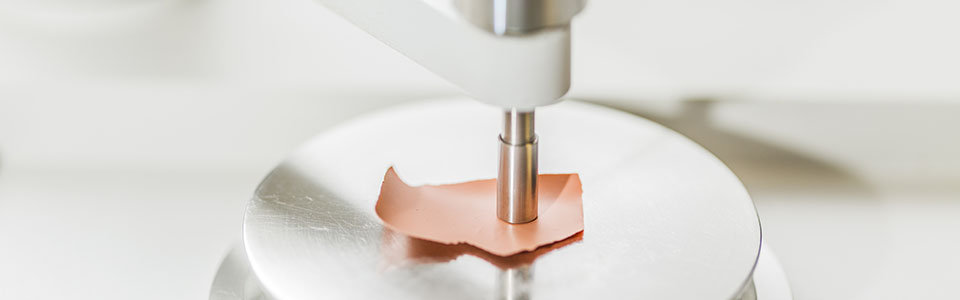

- Determination of the surface energy of substrates (sessile drop) and paints (pendant drop)

- Optical microscopy including the preparation and examination of transverse sections

- Laser scanning microscopy

- SEM / EDX / FIB (Scanning Electron Microscope (SEM) with energy-dispersive x-ray spectroscopy (EDX), Focused Ion Beam)

- Rheological investigations

On account of our long-standing cooperation with external service providers, we also have access to further analytical methods, such as ToF-SIMS and XPS.

We prepare tailored proposals with a selection of suitable analysis methods as well as process analysis and in-process quality control after implementation.

PRACTICAL EXAMPLES

Chemical-physical analysis programs for characterizing/identifying materials and for determining specific material properties

Practical examples:

- Adhesion problems of a tube interior coating .

Outcome: curing temperature in connection with existing organic surface layer - Batches: different application properties when using new product batches of a lubricant varnish.

Outcome: altered composition of paint or binder - Batches: differences in the processing properties of batches of adhesive. Outcome: varying rheological properties

- Blotchy finish: printed, painted decorative paper with uneven, slightly blotchy finish.

Outcome: deviating binder and uneven pigment distribution - Delamination phenomena of a powder coating on steel.

Outcome: inadequate phosphating due to non-conform pre-treatment process - Delamination phenomena on composites made of a plastic substrate and fleece.

Outcome: contamination by silicones and fatty acid esters - Deposits (liquid) in the heat exchanger of a paint shop;

Outcome: constituents of the processed lacquers and coolant - External influence: gelling of various filling contents despite identical composition.

Outcome: metal surfaces of the containers have different structure or properties - Films: formation of white deposits on headlight lenses.

Outcome: substances released from headlight components - Grinding process: Additional effort required to grind and paint plastic components due to frequently protruding fibers and particles.

Outcome: optimization of grinding process / abrasive material after systematically comparing surface topography - Paint deposit on unpainted drive parts. Outcome: paint identical to that on painted parts of the same assembly

- Particles on surface of a sol-gel coating.

Outcome: particles consist of dried paint material - Particles in the sieve residue of a metallic lacquer. Outcome: agglomeration of filler constituents

- Product identity: dispute about identity of a wall coating (specification: silicone resin).

Outcome: wall coating does not comply with specification - Quality control of potting compounds in electrical components with thermal analysis (DSC).

Outcome: one subarea insufficiently cured, adaptation of the curing regime based on DSC results

As a competent contact partner, we will gladly assist you with any problems you may have.

RESEARCH PROJECTS

- UV curing guidelines for organic coatings: Clarification of generally-applicable relationships between curing kinetics and material/performance characteristics

- Influence of plastic additives on the coatings adhesion of add-on parts made of PP materials