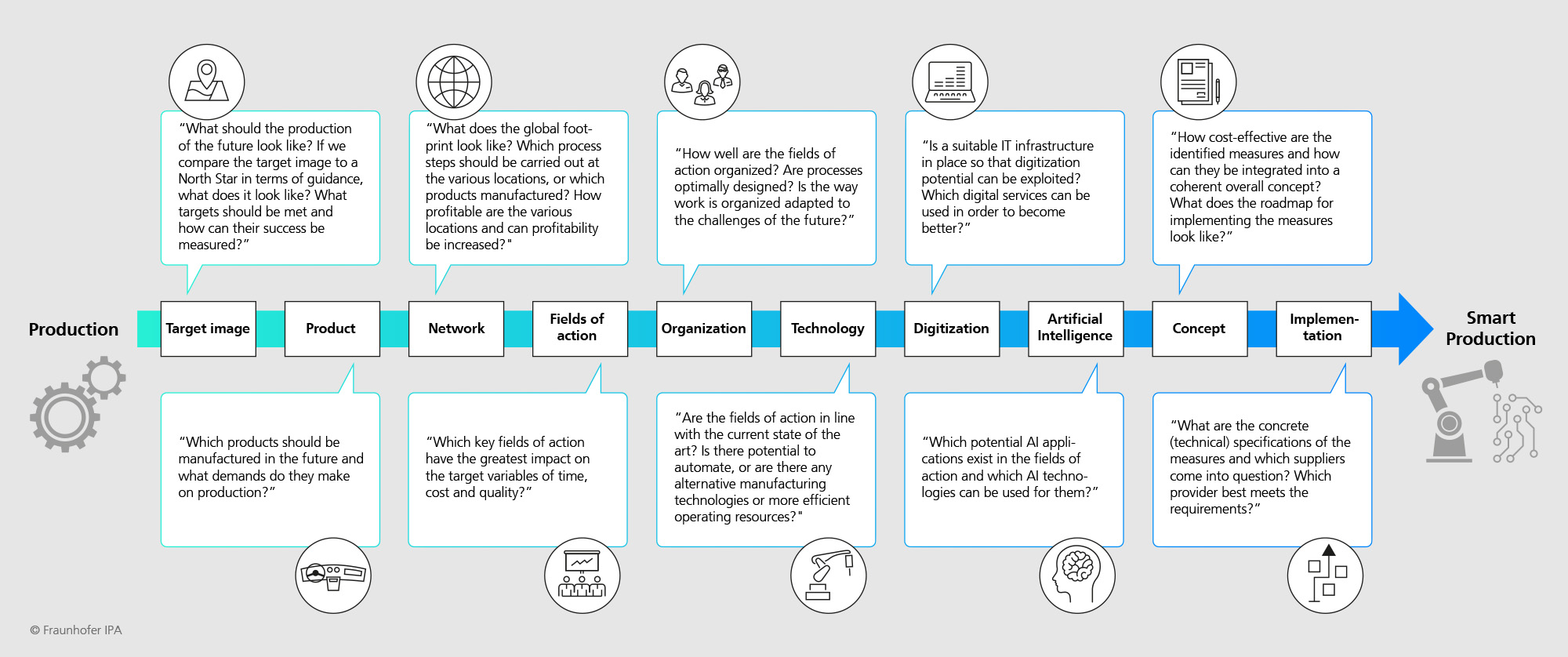

Smart Production

Our understanding of smart production

Disruptive technologies from the fields of digitalization, artificial intelligence, robotics or additive manufacturing open up new opportunities to gain competitive advantages in global markets. As a result, an unprecedented transformation of manufacturing systems, production networks and entire supply chains is currently taking place worldwide. This gives companies the chance to create value chains that are intelligent, flexible, efficient and customer-oriented.

Challenge and benefits

There is enormous pressure to change: decision-makers are increasingly asking themselves which media hype and which technologies are really important when it comes to their own production system. Not every technological innovation is equally relevant to all companies. The resulting uncertainty presents decision-makers with additional challenges in the already demanding process of strategic production realignment.

We help you find out which technologies can add value to your company and where they can be used effectively. New technologies are never an end in themselves, but enable companies to provide efficient and customer-oriented services. Focusing on the right technologies, making value-enhancing investment decisions and drawing up an adequate technology roadmap are essential components of the production strategy that we develop, thus paving the way to smart production. Applying scientifically proven methods, we help you objectively validate the benefits of new technological possibilities in order to prepare your production for the challenges of the future.

Our approach

Together with you, we develop a strategy that optimally aligns your production with future market requirements in terms of cost and revenue. Through our scientifically based and comprehensive approach, as we develop a suitable strategy we bundle the know-how of our technology experts that includes the latest technology impulses from science and practice. We are capable of critically assessing new technological developments to objectively evaluate their relevance for your company. Our approach consists of several phases; throughout each phase we provide you with comprehensive support or alternatively offer targeted assistance in dealing with individual phases.

Target image

Based on future market requirements and your product strategy (if you need help developing a product strategy, our business model experts can assist), we work with you to develop a vision of your production of the future. We capture this vision in a target image. The target image includes aspects from the fields of organization, technology, digitization and artificial intelligence and is a guide that enables you to meet your customers’ future requirements. Via the target image, we define a target and performance indicator system with you. As a result, you can measure and assess the success of the technological change.

Product

Based on your product strategy (if you need help developing a product strategy, our business model experts can assist) we derive the requirements for the manufacturing system, production network and supply chain. We provide support as you introduce new products and check whether you have the necessary skills, technologies and capacities to manufacture them. We also plan the necessary adjustments to your production process.

Network

We analyze your global production network and provide you with the information you need to make decisions on how to shape your global footprint. To this end, we assess the competencies of your production sites and determine which products are manufactured or production processes are carried out there. By developing a sourcing strategy, we define the future supply chain. If individual production sites are struggling to remain profitable, we identify the reasons for this and develop appropriate countermeasures. People often ask how pilot projects that have been successfully tested at some sites can be rolled out to other locations in the production network. To achieve this, we analyze the conditions specific to the production sites concerned and develop an appropriate rollout strategy.

Fields of action

To ensure that the use of new technologies is not an end in itself, we take the formulated objectives (time, costs, quality, etc.) as a basis to identify the key fields of action that will really help you to achieve your goals. These may be individual production areas or products. These fields of action form the core of our strategy development process. Throughout the entire duration of the project, we point out the impact of individual technologies or changes on the formulated goals. In this way, you can be sure that all improvement measures start at the right place.

Organization

We are convinced that an efficient organization is the basic prerequisite when it comes to digitalization and the use of new technologies. Disruptive technologies cause people to change how they want to live and work. This has a strong impact on cooperation - not only within organizations but also across organizational boundaries. In order to create the conditions required to implement the strategy successfully, we first analyze how the fields of action are organized and derive necessary changes to the organization of structures, processes and work activities.

Technology

Our technology experts identify the potential to use technologies and automate your production processes. They also find out how alternative manufacturing technologies (e.g. additive manufacturing) can be implemented and where it makes sense to invest in more efficient equipment to replace existing machines.

Digitalization

To digitalize your company successfully, you need a suitable IT infrastructure. Based on the required capabilities of the production system, we determine the future IT infrastructure and IT system landscape and derive the necessary measures and investments.

Artificial Intelligence

Digitalizing your company creates enormous amounts of data. Artificial intelligence (AI) can help to evaluate this data and derive important information so that you can increase productivity. In addition to data analysis, further potential for enhancing productivity can be tapped by automating previously manual activities with the help of AI. Together with our AI experts, we analyze your fields of action and pinpoint applications that can be improved by implementing AI technologies.

Concept

All the measures identified are examined for their target effect and are then prioritized and put into chronological order. This implementation roadmap is documented as part of a general concept and serves as a basis for your decisions.

Implementation

Together with our technology experts, we assist you in implementing the planned measures. For this purpose, we develop detailed professional concepts that include all technical specifications. Drawing on our extensive knowledge of the market, we help you identify and select suitable suppliers. We provide you with support in the form of coaching when introducing new technologies. Our change management experts assist you in preparing your employees for the upcoming changes.