DesignChain - Automating the CAx process chain

Tabbed contents

EXPERTISE

Mounting price pressure due to the rising number of global suppliers, increasing product individualization and ever-shorter delivery times are challenges faced by industry in the coming years. In this context, mass personalization refers to the individualized manufacture of customer products in batch size 1 at the price of standard products.

The possibilities offered by digitization and by automating technical order processing open up the opportunity for companies to significantly reduce their complexity costs and lead times and thus improve their competitiveness. Many companies are already using a range of CAx tools and configuration solutions today. Expert employee knowledge is often hidden in “knowledge silos” and rarely networked across processes.

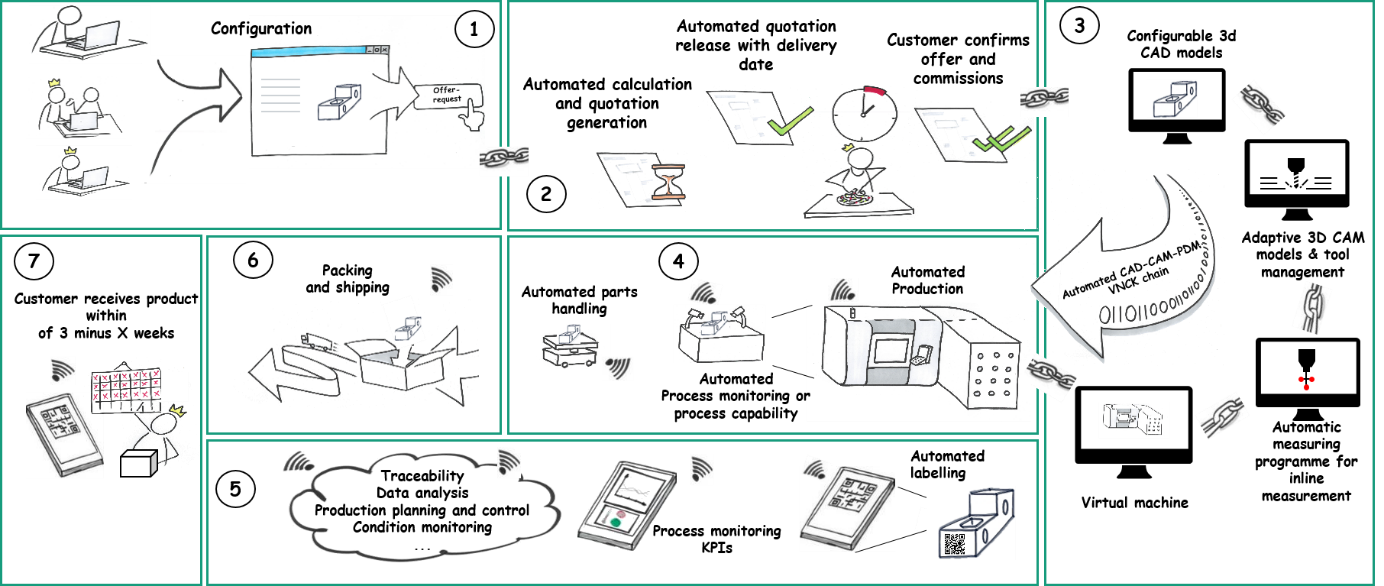

Under the heading DesignChain, Fraunhofer IPA works with you to develop the vision and prototypical implementation of a highly automated end-to-end process - from the systematic recording of customer requirements using company-specific workflows to the transfer of a validated NC code to production. The focus is on methodically structuring and regulating features, closing gaps in the heterogeneous CAx chain and identifying potential cost savings.

Advantages of an end-to-end design chain:

- Shorter delivery times for customized products

- Minimized efforts in indirect areas (sales, design, work preparation, purchasing, production planning, etc.)

- Optimized information flow between departments

- Simplified product structure

How we help you develop an end-to-end design chain:

1. Analysis:

- How products, components and product variants are configured

- Information flow process sequence

- IT infrastructure (CPQ, CRM, ERP, PDM/PLM, CAD , CAE, CAM, MES, CAP, etc.)

- How tools are coupled and their data kept

- Identification of savings potential

2. Prototypical implementation (based on concrete use cases):

- Customer requirements systematically recorded in a standardized language

- Structured configuration level (metaconfiguration, CAD tools, Excel, etc.)

- Regulated object dependencies (configuration elements: bill of materials, work plan, production aids, costing, drawings, roles/persons, documents, quotation texts, network plans)

- Defined configuration-oriented design guidelines + prototypical implementation

- CAD-CAM information exchange, linking (PMI, feature ID, surface ID, color code, etc.) or part-into-part programming

- Development of a business model

3. Implementation support

- Digitization strategies

- Overall project coordination

- Change management