Composite Simulation

The Department of Functional Materials at Fraunhofer IPA pursues a holistic approach to research. We are not only committed to generating knowledge and innovations in applied material research but also want to transfer this knowledge to develop functional prototypes or even marketable products for our customers. To integrate ground-breaking technologies and the latest materials developments into innovative applications and optimized manufacturing processes, simulations and scientific computational models are often indispensable.

Today, the use of computer technology to solve engineering problems is a standard procedure in most sectors of industry. However, as a provider of research services, a mere understanding of these development tools is not enough. Our customers and partners need someone who can offer extensive technical expertise and experience and provide them with the latest technologies and simulation solutions.

The Department of Functional Materials supports the entire development process without the need for costly and time-consuming testing procedures. We answer questions and solve problems in numerous areas – regardless of whether you require information about as-yet unknown material properties or need the features of a functional material to be validated for a newly-developed product.

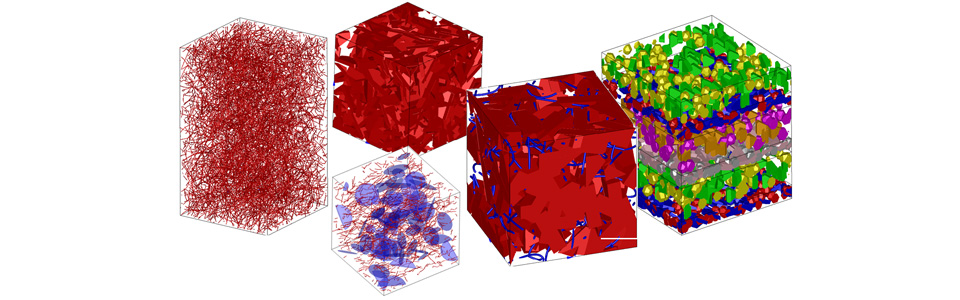

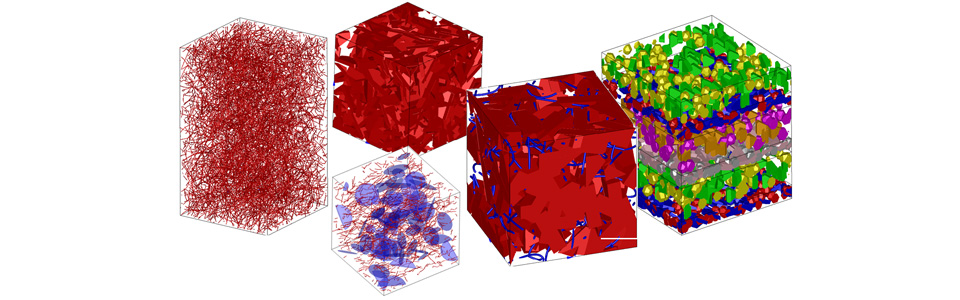

IPA uses two main methods to simulate composite materials: computer aided engineering (CAE) and multiscale simulation. We combine conventional FE-based CAE technology (ANSYS Workbench) with an environment for the multi-scale modeling of composites (DIGIMAT FE). This enables us to extract the material parameters of innovative nano- and micro-composites and develop materials with specific functionalities (virtual material design). The focus of our work is not only on carbon-based particles, such as CNTs and graphene, which are incorporated into a polymer matrix by means of different processes (extrusion, Sol-Gel). We also specialize in metallic inclusions and ceramic matrices, which can be modeled and characterized by this method.

The Department of Functional Materials is an integrated member of the Fraunhofer Gesellschaft and cooperates with numerous research partners. We have established a broad network of research partners and major industrial concerns – also in the field of simulation. Through our participation in public research projects, new simulation applications are always being developed. Examples include the optimization of visco-elastic damping structures and research on electrode technologies for supercaps. These in turn generate new concepts and solutions for tomorrow.