Functional Materials

Tabbed contents

Areas of expertise

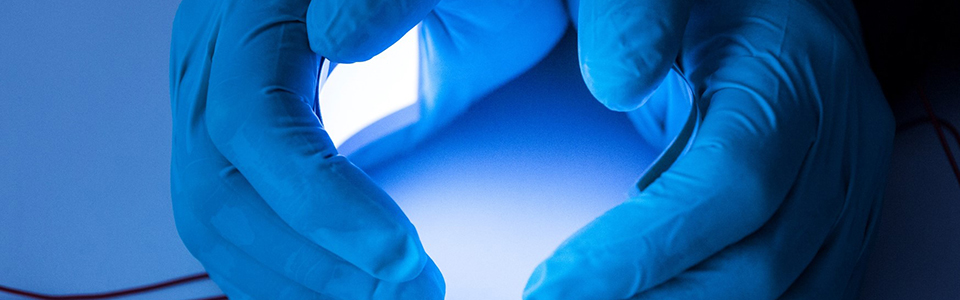

Innovations are increasingly taking place at process level. Nano-modified high-performance materials make plastics more robust, metals lighter and energy storage systems more efficient.

In doing so, conventional materials are modified with nano-scale fillers, such as graphene, nanotubes and silver nano wires. These fillers are synthesized, functionalized, dispersed and applied according to individual customer requirements in our laboratories at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA.

The department has a reactor park, dispersion testing facility as well as a range of pilot application systems. These are used for conventional printing processes and additive manufacturing technologies, such as fused deposition modeling (FDM).

The department is a pioneer in application-orientated material and process research. Today it is recognized as one of the largest research groups active in the field of functional materials. Thanks to its high level of integration, research issues are solved quickly and comprehensively, enabling results to be transferred efficiently to product and process innovations.